A kind of treatment method of waste gas in synthetic leather production process

A production process and treatment method technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as high cost of distilled water, troublesome waste gas treatment methods, complicated process flow, etc., to increase relative humidity and reduce cleaning difficulty , the effect of high spray intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

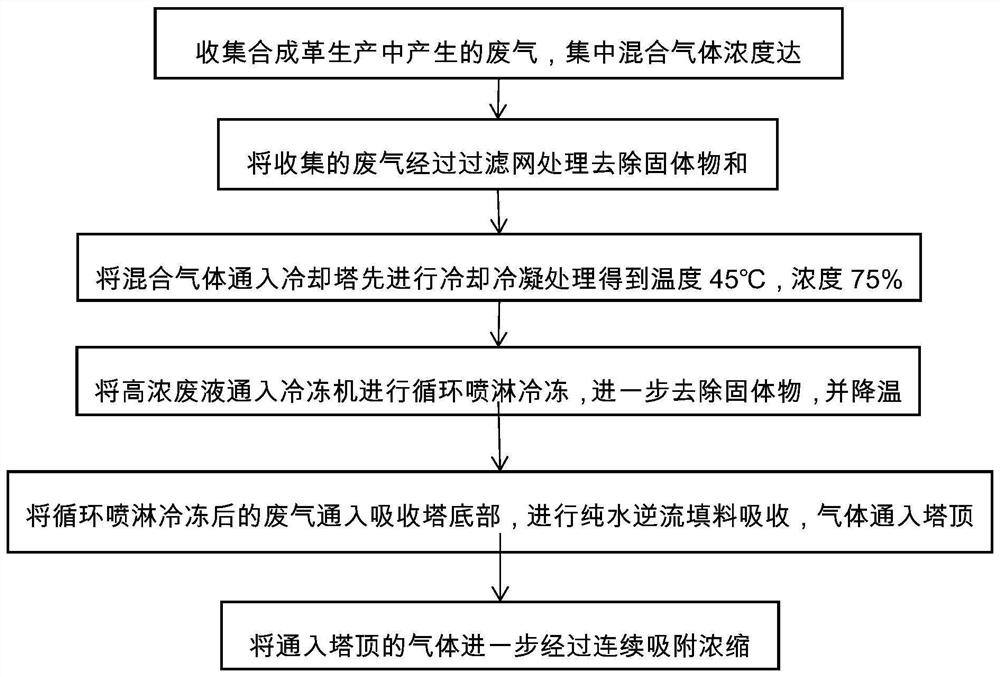

Method used

Image

Examples

Embodiment 1

[0046] Taking a single line of 40000m³ / h, 100°C, 4500mg / m³ DMF, and other components of 500mg / m³ as an example, the outlet temperature of the refrigerated spray circulating liquid is considered as 27°C, the cooling coefficient is considered as 8, and the standard gas volume of the exhaust gas is 29276m³ / h , the cooling and condensing load is Q=550000kcal / h, the heat exchange surface of the cooler is about 350㎡, the cooling fan is 3kw, the circulating water pump is 5.5kw, the refrigeration load is 100000kcal / h, with a 20t / h cooling tower, the power of the refrigerator is 18.5kw, The air pressure of the fan is 4000Pa, the air volume is 33000m³ / h, the power is 55kw, the circulating spray pump is 5.5kw, the desorption fan is 2500Pa, 3600m³ / h, the power is 5.5kw, the total installed power of the system is 93kw, and the power consumption per hour is 79 degrees according to the demand factor of 0.85.

[0047] The cooling condenser adopts a large tube outer film evaporative condenser. ...

Embodiment 2

[0051] Usually, in chemical absorption process, pure absorbent is added to the top of the tower and exhaust gas through the liquid distributor for pure counter-flow mass transfer absorption, so as to have the maximum mass transfer absorption driving force (effective maximum mass transfer concentration difference), but because DMF is water-soluble The water consumption of the dry-process synthetic leather waste gas absorption packing tower is very small, and the wettability of the packing in such a small amount of water (0.15m³ / ㎡.h) will also affect the absorption efficiency, so it is currently used. The dry absorption tower adopts a 3-stage or 4-stage circulation process. Although part of the absorption mass transfer concentration difference is destroyed due to the circulation of the absorption liquid, it can ensure the wettability of the packing and the absorption effect. Under the condition that the DMF components of the exhaust gas discharged from the top reach the standard,...

Embodiment 3

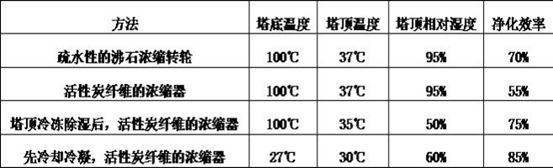

[0056] The above example 2 only considers DMF recovery. If the waste gas of 5000mg / m³ is preferentially collected to remove most of the DMF in the range of 4400-1600mg / m³, there are still other harmful solvent components of about 500mg / m³, which is far from reaching the emission standard and needs to be further However, if the 3-stage or 4-stage circulation of the dry absorption tower is used alone, the temperature of the exhaust gas reaches the top of the tower as high as 37 °C and the relative humidity is as high as 95%, which will affect the subsequent adsorption and concentration efficiency to a certain extent, even if the hydrophobic zeolite is used for concentration. The purification efficiency of the runner is also 60-70%, and the cost of this method is too high; if the lower-cost activated carbon fiber is used, the efficiency of the concentrator is only 50-60%; if the temperature is lowered to 35 °C at this time, the relative humidity will be reduced. To about 50%, it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com