Samarium-cobalt magnet and method for improving solid solubility of Zr element

A samarium cobalt magnet, solid solubility technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve problems such as the inhomogeneity of Zr solid solution can not be completely improved, to improve the performance of magnets, improve stability, improve high temperature stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1: Ingredients and Melting

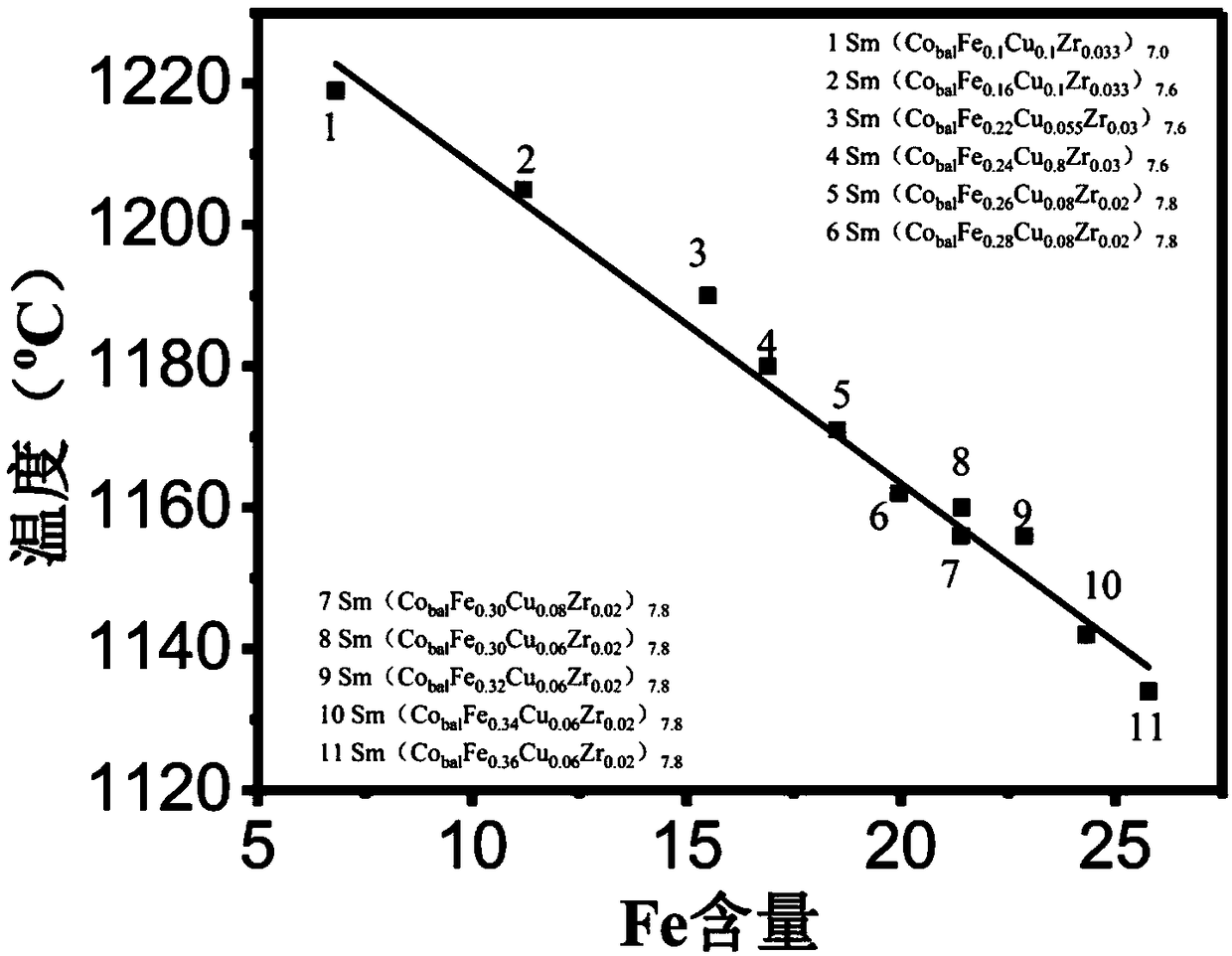

[0048] Rare earth element Sm with a purity of 99.95%, Co with a purity of 99.98%, Cu with a purity of 99.99, Fe and Zr with a purity of 99.9% are used as raw materials, and they are placed in a water-cooled copper crucible in a vacuum arc melting furnace, which is easy to burn The damaged metal Sm was placed at the bottom of the crucible and vacuumed to 2×10 -3 ~5×10 -3 After Pa, fill the furnace body with high-purity argon gas, the volume percentage purity of argon gas is 99.99%, and the vacuum degree in the furnace rises to 0.8×10 5 Stop filling after Pa, repeat the smelting for 3 to 4 times under the conditions of working voltage 30V-45V and working current 600A-800A, and cool down to obtain alloy ingot: Sm(Co 0.767 Fe 0.1 Cu 0。 1 Zr 0.033 ) 7.0 ;

[0049] Step 2: Milling and shaping

[0050] In a glove box filled with high-purity argon with an oxygen content lower than 0.5ppm, the ingot was pulverized with a pulverizer and ...

Embodiment 2

[0059] Step 1: Ingredients and Melting

[0060] Rare earth element Sm with a purity of 99.95%, Co with a purity of 99.98%, Cu with a purity of 99.99, Fe and Zr with a purity of 99.9% are used as raw materials, and they are placed in a water-cooled copper crucible in a vacuum arc melting furnace, which is easy to burn The damaged metal Sm was placed at the bottom of the crucible and vacuumed to 2×10 -3 ~5×10 -3 After Pa, fill the furnace body with high-purity argon gas, the volume percentage purity of argon gas is 99.99%, and the vacuum degree in the furnace rises to 0.8×10 5 Stop filling after Pa, repeat the smelting for 3 to 4 times under the conditions of working voltage 30V-45V and working current 600A-800A, and cool down to obtain alloy ingot: Sm(Co 0.65 Fe 0.24 Cu 0。 08 Zr 0.03 ) 7.6 ;

[0061] Step 2: Milling and shaping

[0062] In a glove box filled with high-purity argon with an oxygen content lower than 0.5ppm, the ingot was pulverized with a pulverizer and ...

Embodiment 3

[0071] Step 1: Ingredients and Melting

[0072] Rare earth element Sm with a purity of 99.95%, Co with a purity of 99.98%, Cu with a purity of 99.99, Fe and Zr with a purity of 99.9% are used as raw materials, and they are placed in a water-cooled copper crucible in a vacuum arc melting furnace, which is easy to burn The damaged metal Sm was placed at the bottom of the crucible and vacuumed to 2×10 -3 ~5×10 -3After Pa, fill the furnace body with high-purity argon gas, the volume percentage purity of argon gas is 99.99%, and the vacuum degree in the furnace rises to 0.8×10 5 Stop filling after Pa, repeat the smelting for 3 to 4 times under the conditions of working voltage 30V-45V and working current 600A-800A, and cool down to obtain alloy ingot: Sm(Co 0.60 Fe 0.32 Cu 0。 06 Zr 0.02 ) 7.8 ;

[0073] Step 2: Milling and shaping

[0074] In a glove box filled with high-purity argon with an oxygen content lower than 0.5ppm, the ingot was pulverized with a pulverizer and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com