Polymer solution-based magnetofluid self-assembly needle-free electro-spinning device and nanofiber electro-spinning method thereof

A technology of polymer solution and magnetic fluid, which is applied in the direction of single-component synthetic polymer rayon, electrospinning, fiber treatment, etc. Problems such as complex structure of spinning equipment and difficulty in stable control of the production process to achieve the effects of simplified structure, continuous specification and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

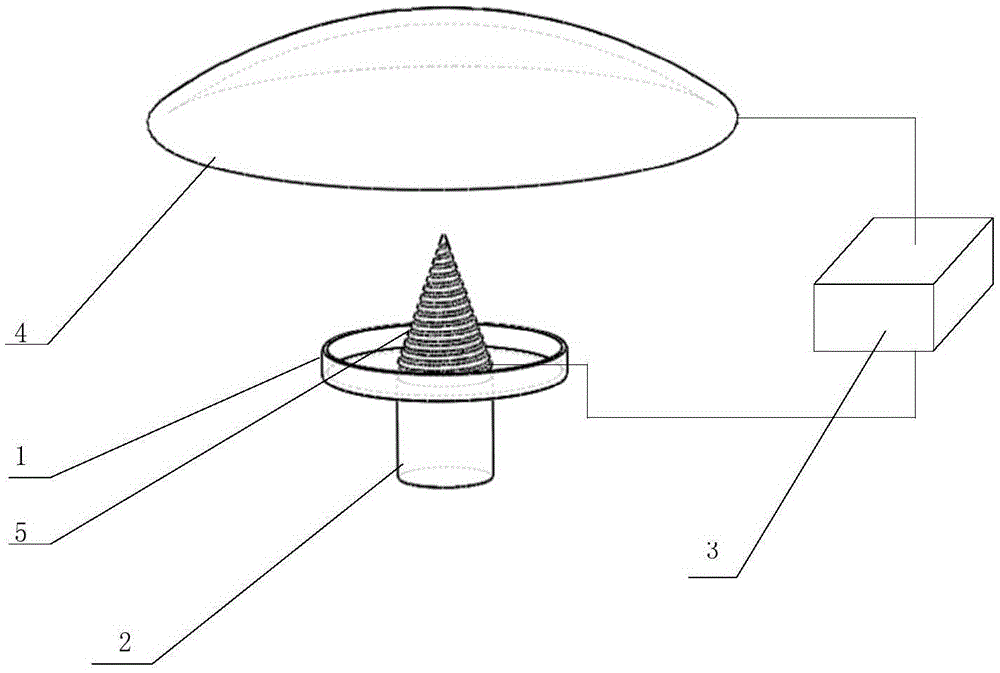

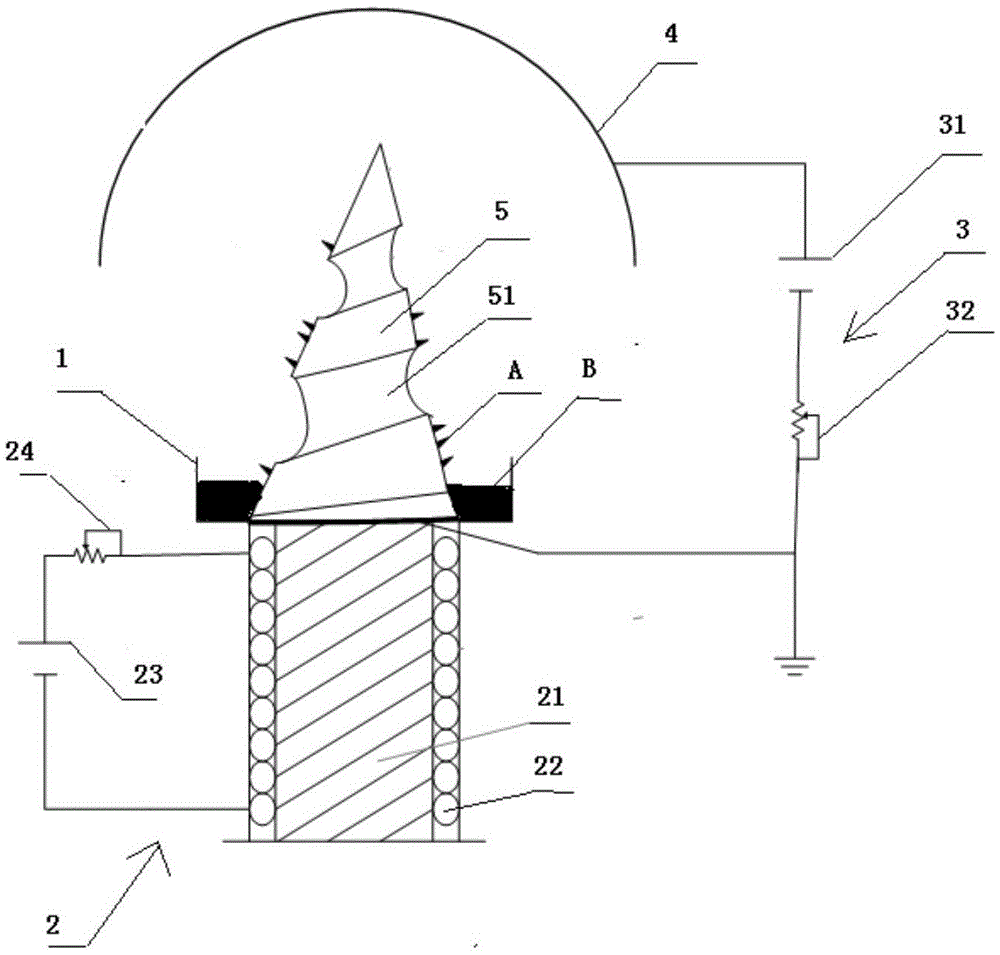

[0034] Such as figure 1 and 2 As shown, this embodiment provides a polymer solution-based ferrofluid self-assembled needle-free electrospinning device, which includes a groove 1 made of plexiglass, a controllable magnetic field generating module 2, a high-voltage electric field generating module 3, and is used to collect fibers. The conductive fiber receiving module 4 of silk and a conical tower 5 with electrical conductivity and magnetic permeability, the surface of the conical tower 5 is provided with a threaded groove 51 spirally rising along the conical tower 5;

[0035]The conical tower 5 is evenly distributed in the groove 1, the fiber receiving module 4 is arranged above the conical tower 5, and the controllable magnetic field generating module 2 is arranged below the groove 1 and is used to apply a controllable The magnetic field is on the conical tower 5 , one end of the high-voltage electric field generating module 3 is electrically connected to the fiber receiving ...

Embodiment 2

[0047] In this example, also refer to figure 1 and figure 2 , the polymer solution-based ferrofluid self-assembled needle-free electrospinning device is substantially the same as in Example 1, the difference being specifically: the taper of the conical tower 5 is 0.18; the height of the conical tower 5 is is 6.67cm; the depth of the thread groove 51 is 0.30cm; the pitch of the thread groove 51 is 0.65cm, and the distance between the fiber receiving module 4 and the groove 1 is 18cm.

[0048] In the production process, the specific method of electrospinning nanofibers is as follows:

[0049] S1: Add an appropriate amount of high molecular polymer solution-based magnetic fluid B to the groove 1; the preparation method of high molecular polymer solution-based magnetic fluid B is: first configure the polyvinyl alcohol (PVA) with a mass volume ratio of 7wt%. Aqueous solution, after mixing evenly, add 0.2g / ml of coated Fe3O4 powder into the above solution and mix evenly;

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com