Automobile slotless AC electric generator

A technology for alternators and automobiles, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problem of insufficient power generation efficiency, achieve the effects of enhanced induction magnetic field strength, optimized magnetic permeability, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

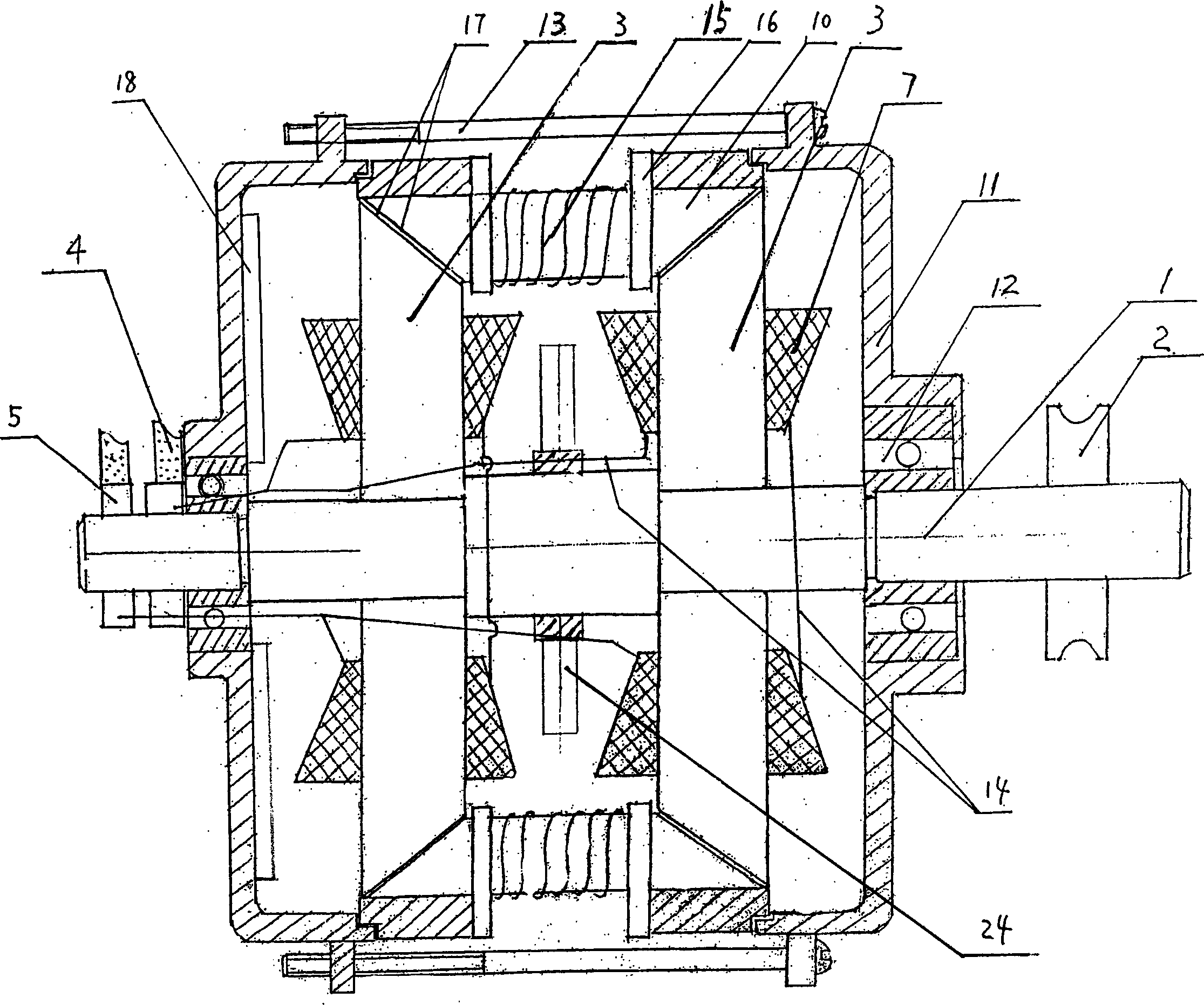

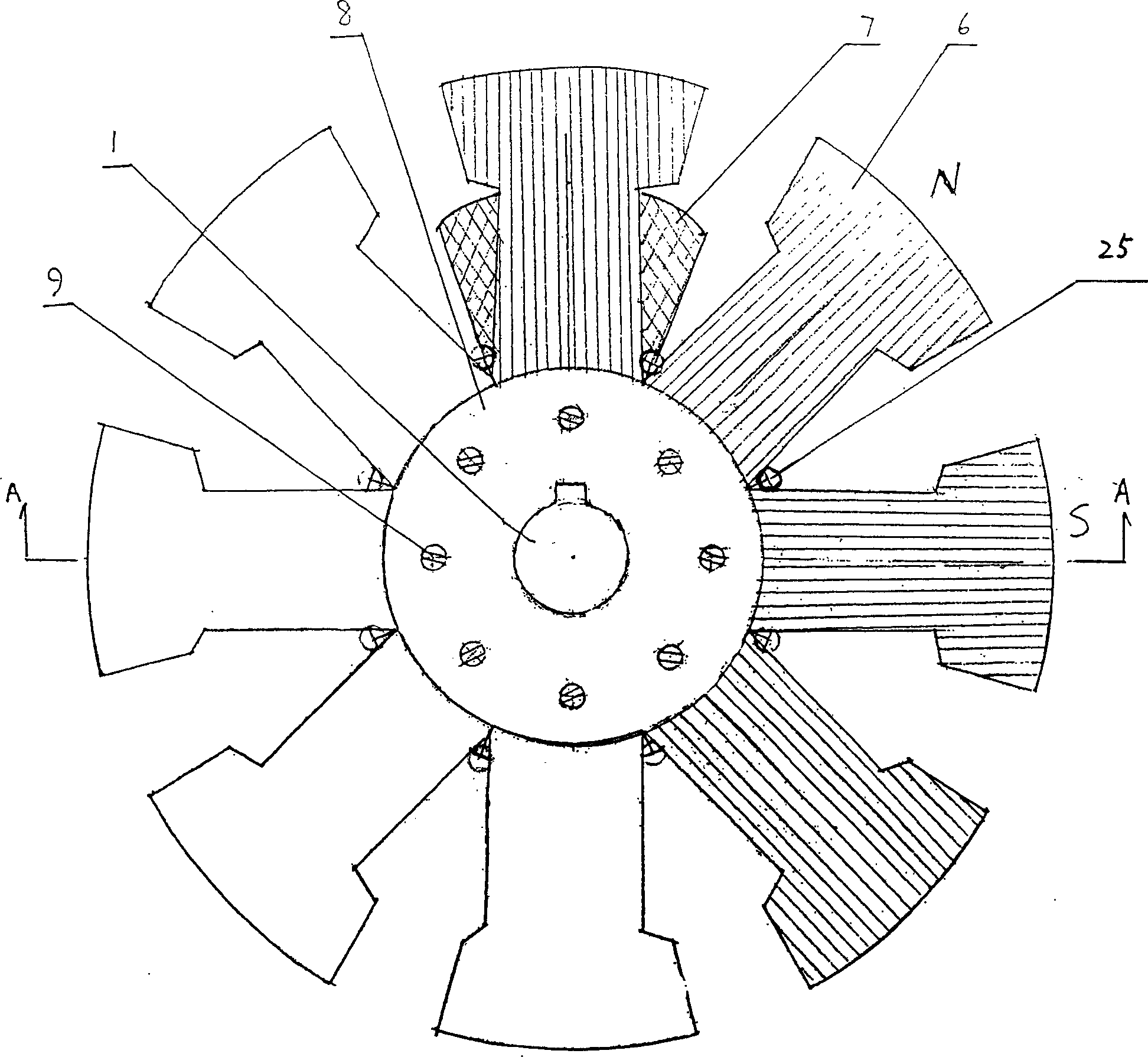

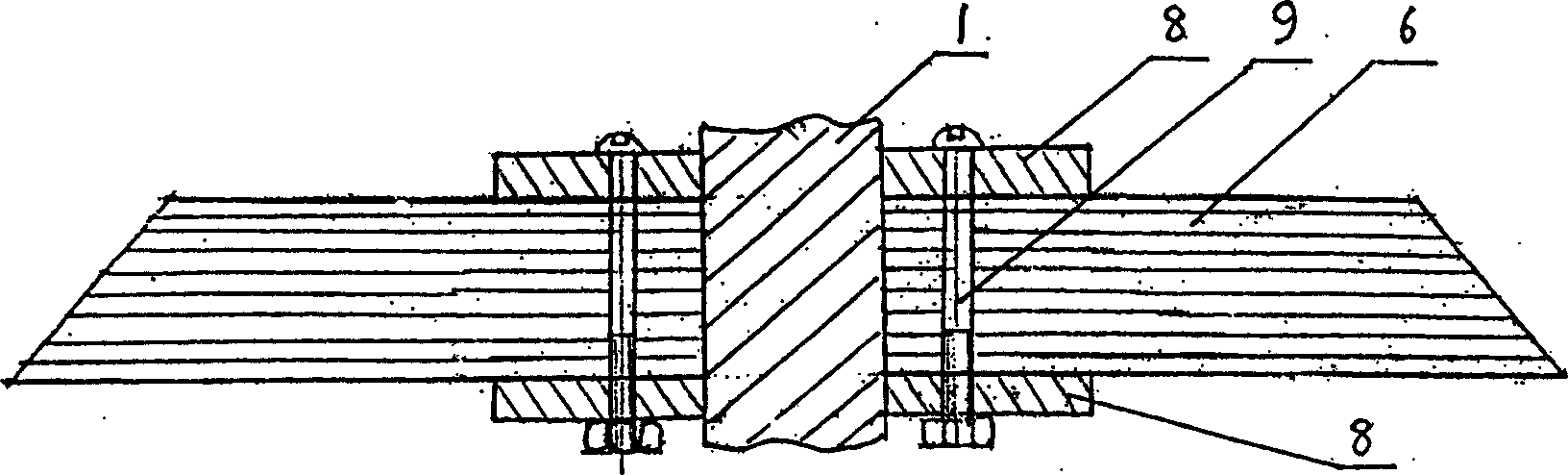

[0022] Referring to the accompanying drawings, the automobile slotless alternator described in the embodiment includes a stator, a rotor and a rectifier 18 . The rotor includes a rotating shaft 1 supported by bearings 12 on the left and right end covers 11. The left and right end covers 11 are fixed by end cover fixing bolts 13. The rotating shaft 1 is covered with an inherent pulley 2, two pole plates 3 and carbon brushes 4. The contact slip ring 5, the shaft 1 is cylindrical and stepped, the middle section between the two pole disks 3 is the thickest, and the two end sections are the thinnest, and the inherent fan is set on the middle section of the shaft 1 between the two pole disks 3 Blades 24, each pole disc 3 of the rotor includes 8 magnetic poles 6 uniformly arranged radially, the inner section of each magnetic pole 6 is closely adjacent, and the outer section is a thickened trapezoidal surface, the bottom of the trapezoidal surface is arc-shaped, Ventilation holes 25 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com