Annealing separant for high-magnetic-induction oriented silicon steel and preparation method thereof

An annealing release agent and high magnetic induction orientation technology, which is applied in the field of release agent and preparation for silicon steel, can solve the problems of uneven atmosphere and increased dew point, and achieve the effects of good insulation performance, reduced yield ratio, and excellent magnetic induction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below:

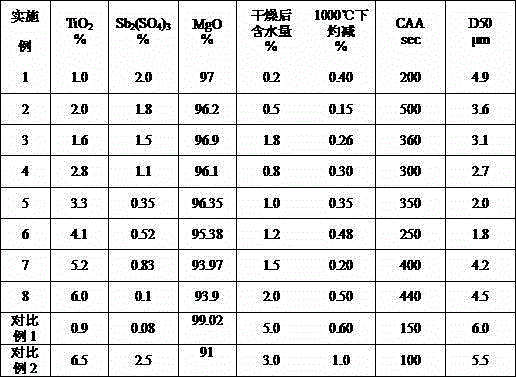

[0023] Table 1 is the raw material composition and content list of each embodiment of the present invention and comparative example;

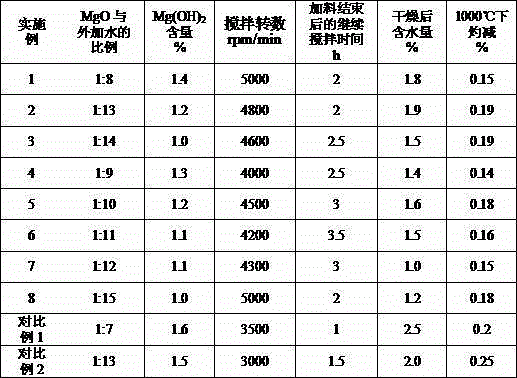

[0024] Table 2 is the main process parameter value list of each embodiment of the present invention and comparative example;

[0025] Table 3 is a list of the performance test results of each embodiment of the invention and the comparative example.

[0026] Each embodiment of the present invention is produced according to the following steps:

[0027] 1) Mix MgO and water, the ratio of MgO to water is 1:8~15, and stir well and evenly; control Mg(OH) 2 Amount <1.5%;

[0028] 2) Add TiO according to 1~6% 2 , and stir well and evenly;

[0029] 3) Add Sb according to 0.1~2% 2 (SO 4 ) 3, and stir;

[0030] 4) Sb 2 (SO 4 ) 3 After the addition, continue to stir for no less than 2 hours;

[0031] 5) Standby.

[0032] The data of each embodiment in Table 1 and Table 2 are not in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com