Making process of electromagnetically shielding composite wooden material

A composite material, electromagnetic shielding technology, applied in the fields of magnetic/electric field shielding, shielding, impregnating wood, etc., can solve the problems of inability to achieve electromagnetic shielding effect, poor durability of the adhesive layer, harsh conditions, etc. Low, strong bond effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

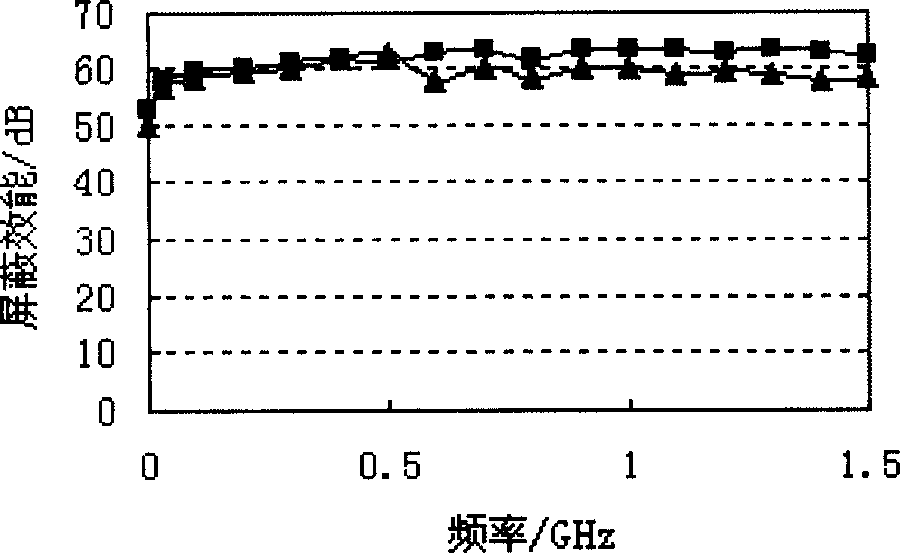

[0006] Embodiment 1: The electromagnetic shielding wood composite material is prepared in this embodiment according to the following steps: a. Immerse the wood veneer in a colloidal palladium liquid, and treat it at room temperature for 2-12 minutes. The micelle; b. After taking out, wash with water, and then immerse it in a dilute hydrochloric acid solution for 0.5-2min. This process is to expose the zero-valent metal palladium and play a role in the catalytic chemical plating process; c. Remove the wooden veneer from the hydrochloric acid solution. Take out and wash with distilled water; d. Then place the wooden veneer in a reaction tank filled with a nickel plating solution, and the ratio of the amount of the plating solution to the surface area of the wooden veneer is about 100-300 mL / dm 2 , the bath temperature is 45~95℃, and the plating time is 20~90min, so that the Ni-P alloy coating is continuously deposited on the surface of the wood veneer, and a uniform and continu...

specific Embodiment approach 2

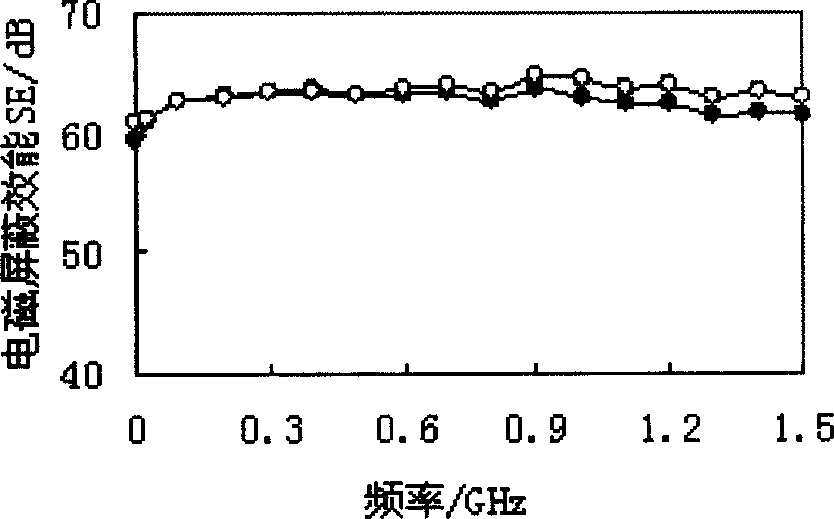

[0008] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in order to improve the electromagnetic shielding effect, the surface of the Ni-P alloy coating is chemically plated with copper, and the wooden veneer is placed in a reaction tank containing a copper plating solution. , the ratio of the plating solution to the surface area of the wood veneer is about 100 to 300 mL / dm 2 , the temperature of the plating solution is 45 to 95 °C, and the plating time is 20 to 90 minutes, so as to form a Ni-Cu composite coating with both corrosion resistance and good electrical conductivity. In this embodiment, the copper plating solution is composed of the following components: 15-35 g / L copper sulfate, 20-60 g / L potassium sodium tartrate, 8-20 mL / L formaldehyde, and the pH of the copper plating solution is 10-13.

specific Embodiment approach 3

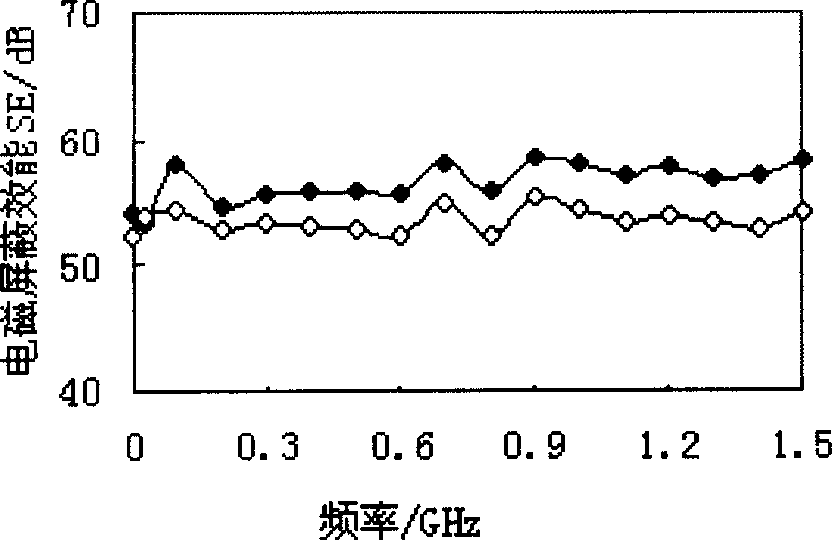

[0009] Embodiment 3: In this embodiment, the compositions of the nickel plating solution, the copper plating solution and the colloidal palladium liquid are shown in Tables 1, 2 and 3.

[0011] copper sulfate

[0012] PdCl 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com