Explosion-proof high-low-temperature test chamber

A technology of high and low temperature test chambers and explosion-proof chambers, which is applied in vehicle testing, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as high daily use costs, inability for users to load fuel, and inability to obtain explosion-proof certification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

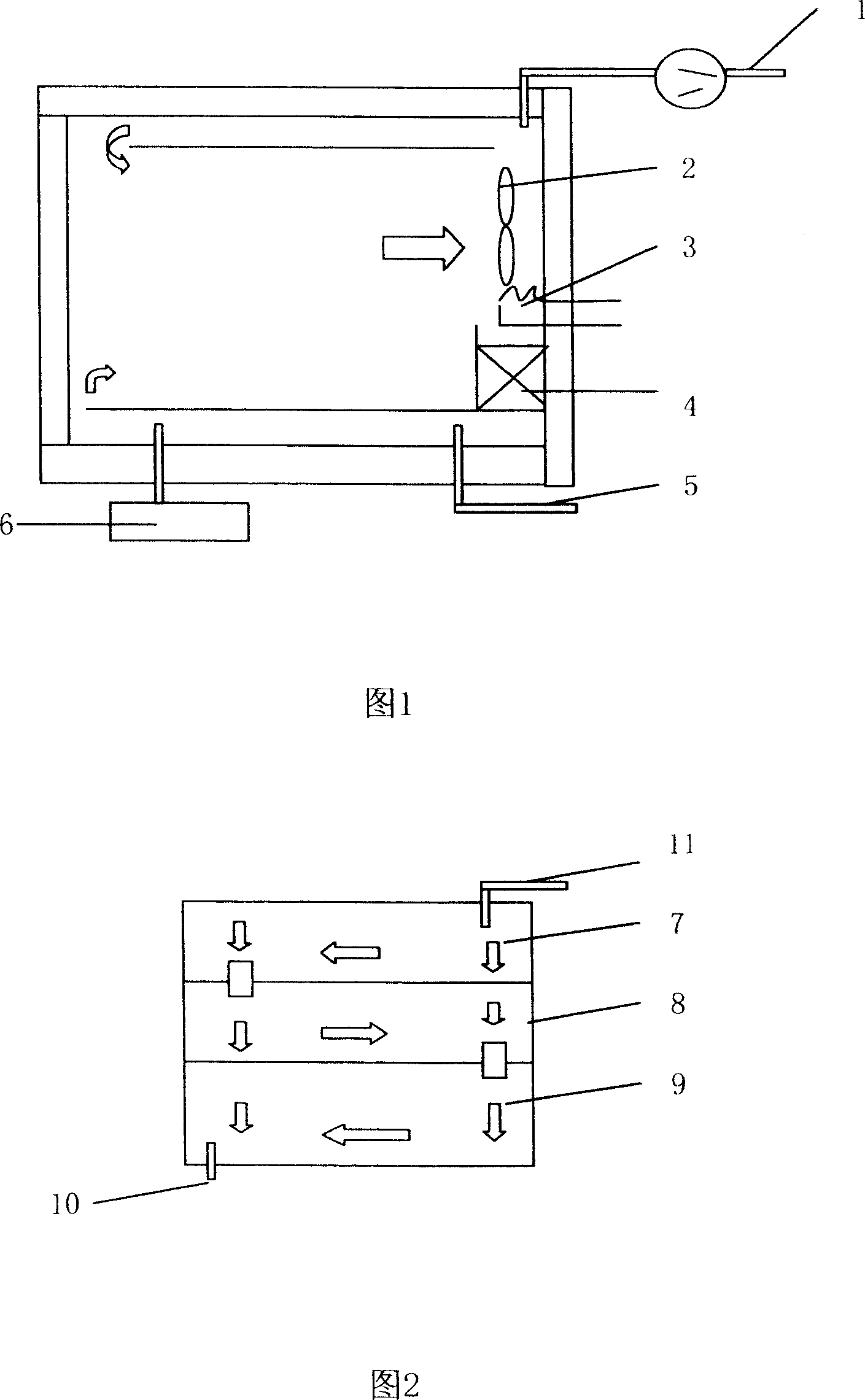

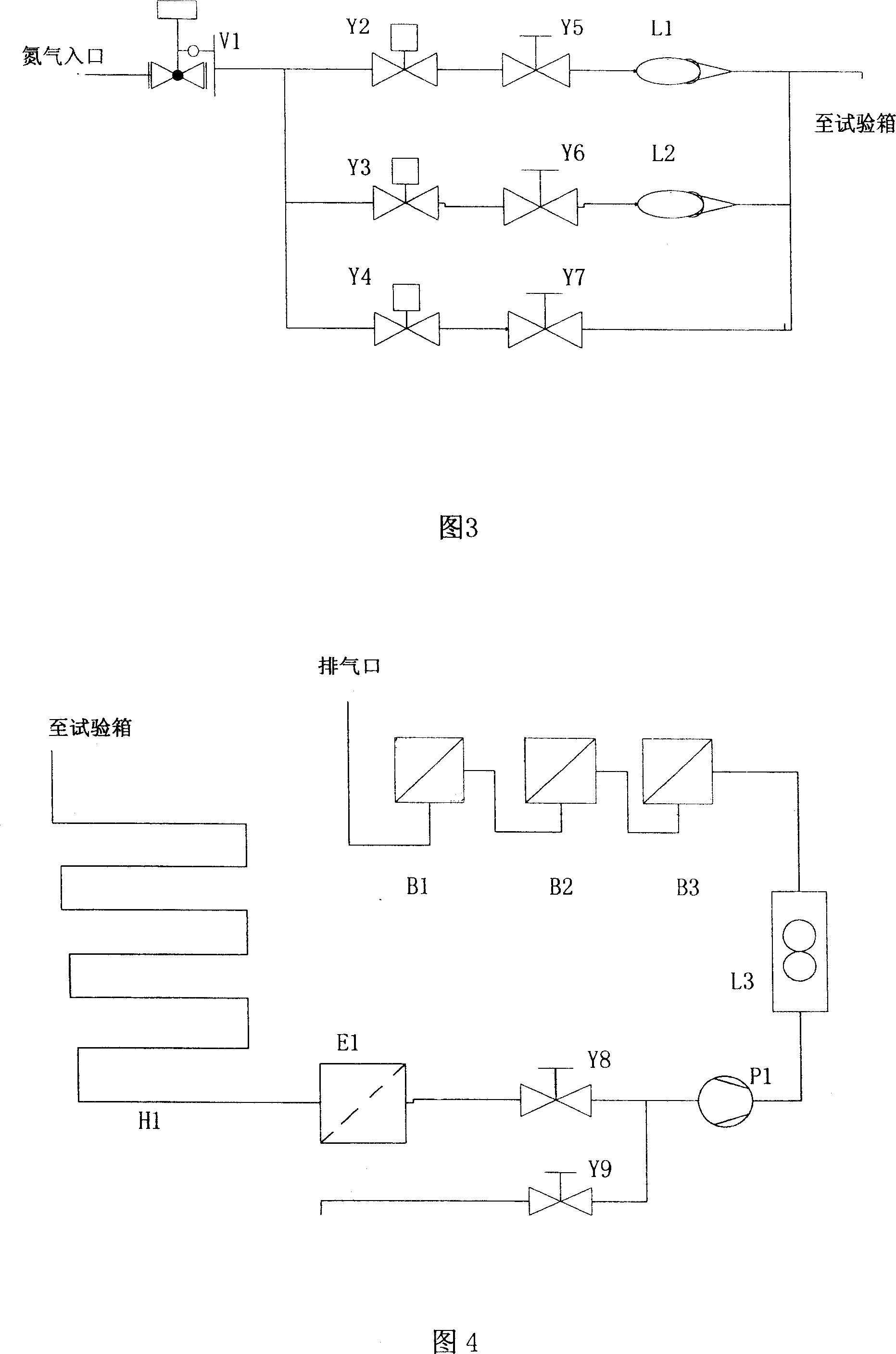

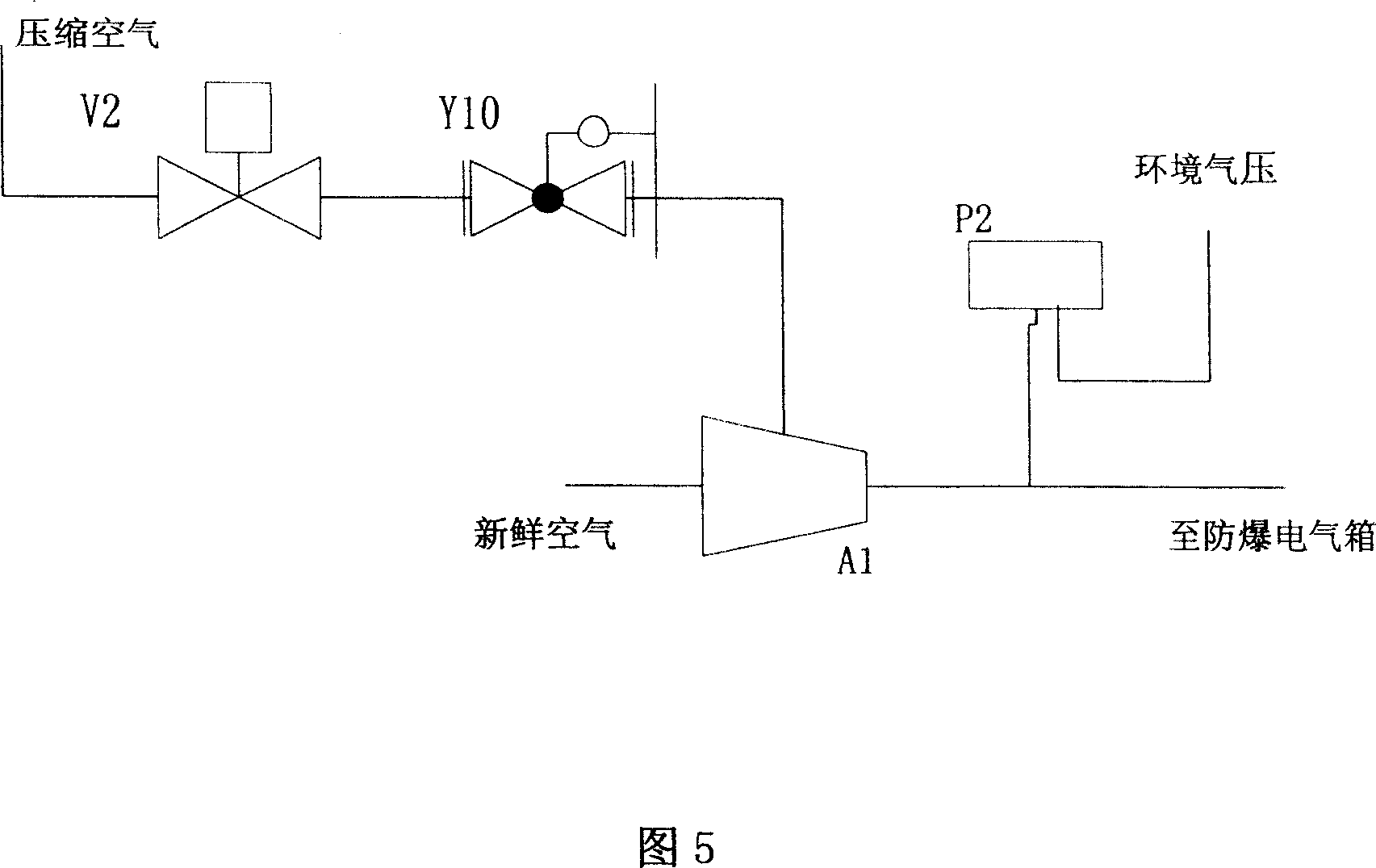

Embodiment Construction

[0018] Combustion requires three conditions: the presence of combustible substances, combustion-supporting substances and ignition sources, and the absence of any of these three conditions will not cause combustion. Because the combustible substance that has in the present invention is mainly gasoline (flash point: between-58~10 ℃; Ignition energy: 0.2~0.25 millijoule; Spontaneous ignition point: 390~530 ℃; Gasoline explosion upper limit: 7.6%; Gasoline explosion Lower limit: 1.0%; coefficient of expansion: 0.1%). Gasoline combustors are oxygen in the air, and the minimum oxygen content required for gasoline combustion is 11.7% to 14.4%. If the oxygen content in the test chamber can be controlled within 2%, safety and effective explosion protection can be ensured. In addition, it is also necessary to control the ignition source. According to GB3836.1-2000, the explosive gas mixture of gasoline, diesel and kerosene is grouped into T3 (ignition temperature: 200℃<T≤300℃; maximum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com