Magnetic field loomage as well as preparation method and application thereof

A magnetic field and fabric technology, applied in the direction of magnetic field/electric field shielding, shielding, fabrics, etc., can solve the problems of hard fabrics, easy to rust and break, poor wearability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of permalloy wire:

[0037] Permalloy 1J85 drawn into filaments, wire diameter 0.15mm;

[0038] Softening annealing: the annealing temperature is 1050°C~1080°C, and the passing speed of the permalloy wire is 2~8 m / min;

[0039] Magnetic annealing: first keep the temperature in the annealing furnace at 1050°C-1150°C for 5 hours, then cool at a rate of 150°C / hour to 500°C-700°C, then quickly cool at a rate of 400°C / hour to 200°C, and then air-cool ( cooled in air) to room temperature.

[0040] The prepared permalloy wire is soft and has certain magnetic properties.

[0041] The above permalloy wire is used as the weft yarn, and 32 s / 2 Combed cotton yarn is used as warp yarn, after warping, it is weaved on the machine.

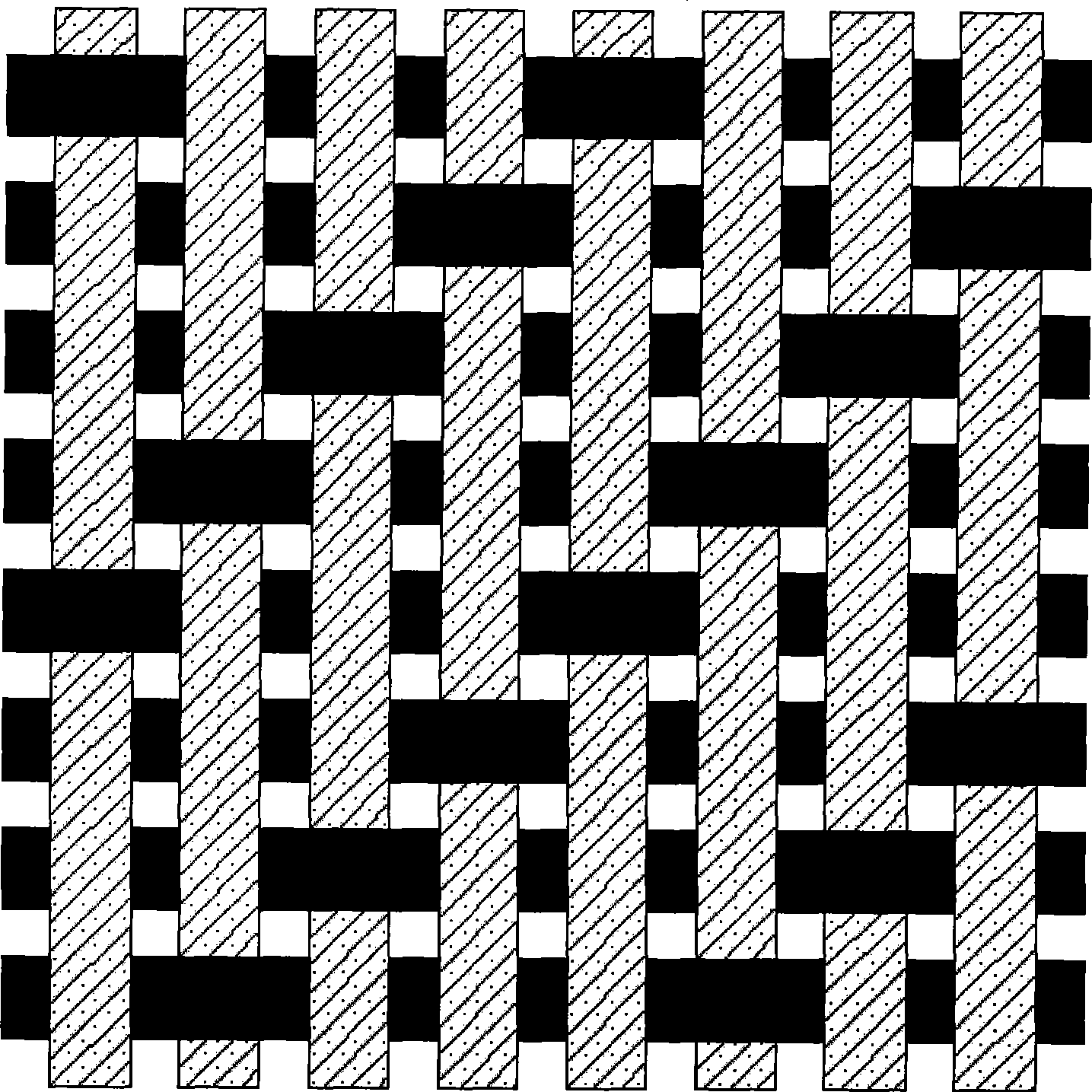

[0042] The fabric structure uses 5 pieces of 2-flying satin weave.

[0043] The warp density is 272 / 10cm, and the weft density is 400 / 10cm.

[0044] Test results: see Table 1.

[0045] Table 1

[0046]

Embodiment 2

[0048] Preparation of permalloy wire:

[0049] Permalloy 1J79 drawn into filaments, wire diameter 0.10mm;

[0050] Softening annealing: the annealing temperature is 1050°C~1080°C, and the passing speed of the permalloy wire is 2~8 m / min;

[0051] Magnetic annealing: Firstly, control the temperature in the annealing furnace at 1050°C to 1150°C for 5 hours, then cool to 500°C to 700°C at a rate of 150°C / hour, then quickly cool to 200°C at a rate of 500°C / hour, and then air cool to room temperature.

[0052] The prepared permalloy wire is soft and has certain magnetic properties.

[0053] Adopt 21 s The combed polyester-cotton yarn is used as the warp yarn; the above-mentioned permalloy wire is used as the weft yarn, which is woven on the machine after warping.

[0054] The organizational structure is 3 / 1 right twill.

[0055] The fabric warp density is 312 / 10cm; the weft density is 440 / 10cm. ,

[0056] Test results: see Table 2.

[0057] Table 2

[0058]

Embodiment 3

[0060] Preparation of permalloy wire:

[0061] Permalloy 1J79 drawn into filaments, wire diameter 0.035mm;

[0062] Softening annealing: the annealing temperature is 1050°C~1080°C, and the passing speed of the permalloy wire is 2~8 m / min;

[0063] Magnetic annealing: First, control the temperature in the annealing furnace at 1050°C to 1150°C for 2 hours, then cool to 500°C to 700°C at a rate of 200°C / hour, then quickly cool to 200°C at a rate of 450°C / hour, and then air cool to room temperature.

[0064] The prepared permalloy wire is soft and has certain magnetic properties.

[0065] Adopt above-mentioned permalloy wire to make weft yarn, above-mentioned permalloy wire and 80 s / 2 The combed cotton yarn is arranged in a 2:1 arrangement as the warp yarn, and is weaved on the machine after warping. 3 / 1 right twill weave is applied in the fabric weave structure.

[0066] The warp density is 360 / 10cm, and the weft density is 272 / 10cm.

[0067] The fabric is soft and dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com