High strength nanometer modified ultrafilter membrane and preparation method thereof

A nano-modification and ultrafiltration membrane technology, applied in the field of ultrafiltration membranes, can solve problems such as low strength of ultrafiltration membranes, shortened membrane service life, and affecting membrane service life, and achieves simple membrane forming process, extended service life, and easy The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

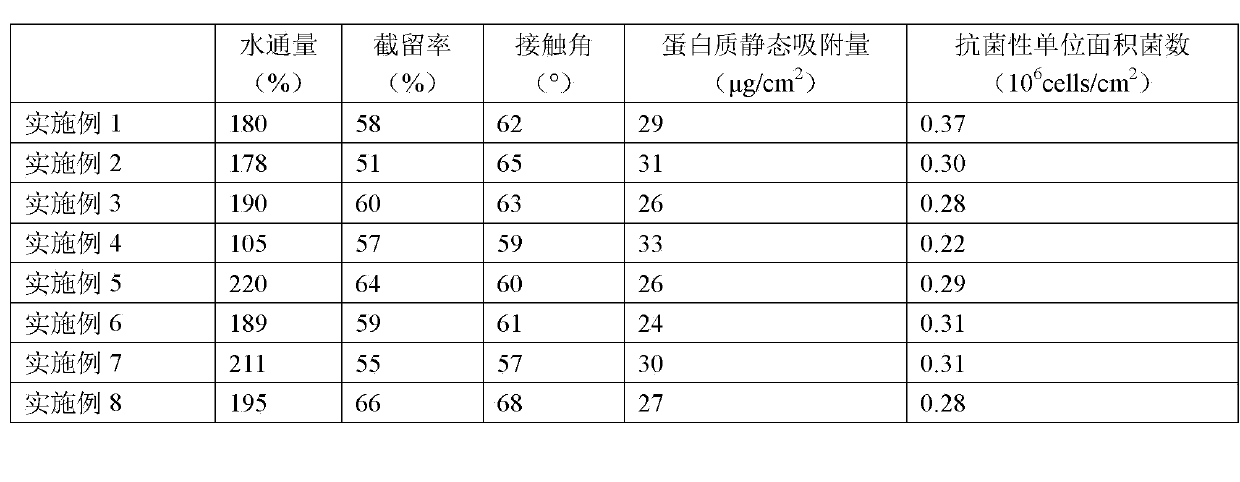

Examples

Embodiment 1

[0032] A high-strength nano-modified ultrafiltration membrane, the preparation steps of which are:

[0033] 1) Ultrasonic disperse carbon nanotubes with a diameter of 20nm in dimethylacetamide to form a uniform dispersion, then place polyvinylidene fluoride, polyvinyl alcohol and polyethylene glycol in the dispersion, and fully Dissolve and ultrasonically stir evenly;

[0034] The proportion of each component is: 40 parts of polyvinylidene fluoride, 8 parts of polyvinyl pyrrolidone, 5 parts of polyvinyl alcohol, 20 parts of polyethylene glycol and 0.05 part of carbon nanotube.

[0035] 2) Stir the mixed solution obtained in step 1) at 80°C for 3 hours, then let it stand at 45°C for 10 hours to obtain a casting solution;

[0036] 3) Scrape the film casting solution in step 2 on the plate, and then put the scraped film into an ethanol solution with a volume concentration of 30% to solidify to form a film;

[0037] 4) The film in step 3) is cross-linked with glutaraldehyde vapo...

Embodiment 2

[0041] A high-strength nano-modified ultrafiltration membrane, the preparation steps of which are:

[0042] 1) Ultrasonic disperse carbon nanotubes with a diameter of 50nm in dimethylacetamide to form a uniform dispersion, then place polyvinylidene fluoride, polyvinyl alcohol and polyethylene glycol in the dispersion, and fully Dissolve and ultrasonically stir evenly;

[0043] The ratio of each component is: 60 parts of polyvinylidene fluoride, 2 parts of polyvinylpyrrolidone, 10 parts of polyvinyl alcohol, 5 parts of polyethylene glycol, 0.5 parts of carbon nanotubes and 0.05 parts of nano titanium dioxide.

[0044] 2) Stir the mixed solution obtained in step 1) at 50°C for 5 hours, and then let it stand at 60°C for 5 hours to obtain a casting solution;

[0045]3) Scrape the film casting solution in step 2) on the plate, and then put the scraped film into an ethanol solution with a volume concentration of 40% to solidify to form a film;

[0046] 4) Cross-linking the film in...

Embodiment 3

[0050] A high-strength nano-modified ultrafiltration membrane, the preparation steps of which are:

[0051] 1) Ultrasonic disperse carbon nanotubes with a diameter of 100nm in dimethylacetamide to form a uniform dispersion, then place polyvinylidene fluoride, polyvinyl alcohol and polyethylene glycol in the dispersion, and fully Dissolve and ultrasonically stir evenly;

[0052] The ratio of each component is: 50 parts of polyvinylidene fluoride, 10 parts of polyethylene glycol and 2 parts of nano-titanium dioxide, the mass ratio of polyvinylpyrrolidone to polyvinylidene fluoride is 0.05 (2.5 parts), polyvinyl alcohol and polyvinylidene The mass ratio of vinylidene fluoride is 0.15 (7.5 parts), and the mass ratio of carbon nanotubes to polyvinylidene fluoride is 0.002 (0.1 part).

[0053] 2) Stir the mixed solution obtained in step 1) at 60°C for 8 hours, then let it stand at 40°C for 7 hours to obtain a casting solution;

[0054] 3) Scrape the casting solution in step 2 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com