Preparation method of organosilicon film and application of organosilicon film in pervaporation treatment of high-salinity wastewater

An organosilicon and organosilicon source technology, which is applied in osmosis/dialysis water/sewage treatment, energy waste water treatment, water/sewage treatment, etc., can solve problems such as increased operating pressure, large steam consumption, and difficulty in cleaning, and achieves increased The effect of driving force, low equipment investment, high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

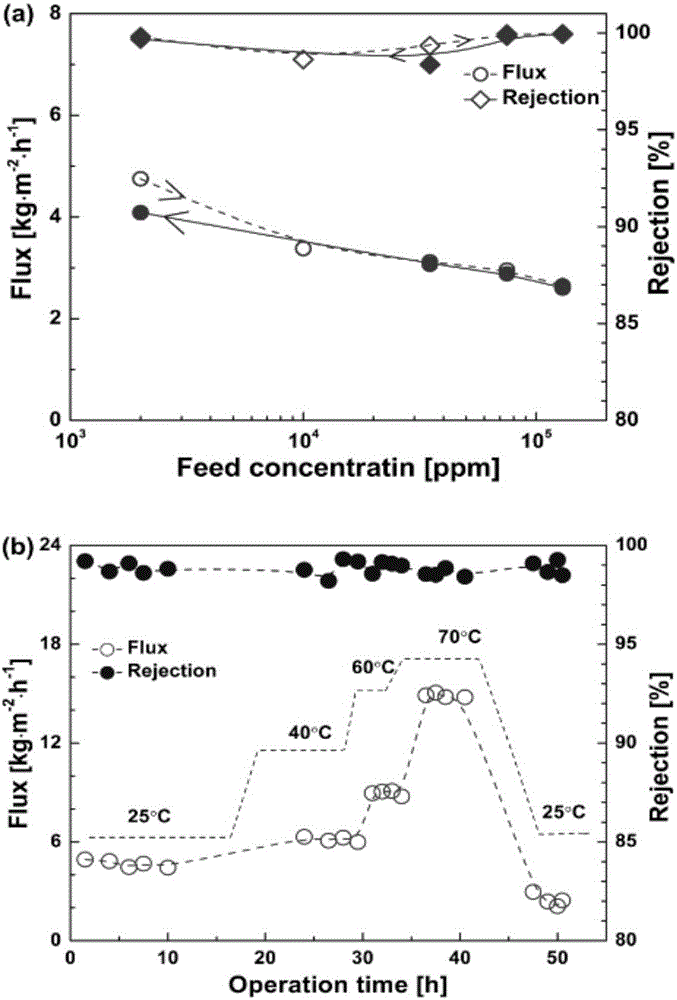

Examples

Embodiment 1

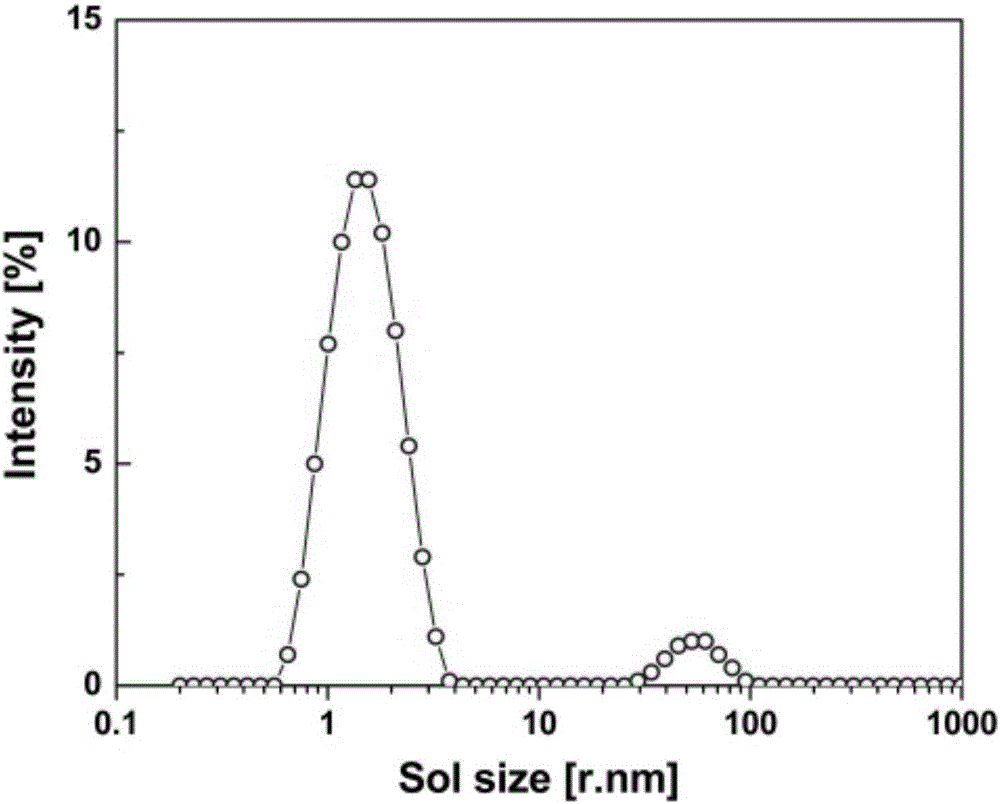

[0033] (1) Add BTESE to absolute ethanol, then add deionized water drop by drop under stirring conditions, and finally add hydrochloric acid dropwise, the molar ratio of hydrogen chloride in BTESE, deionized water, and hydrochloric acid is 1:60:0.2, 40°C Stir in a water bath for 2 hours to obtain an organosilicon sol;

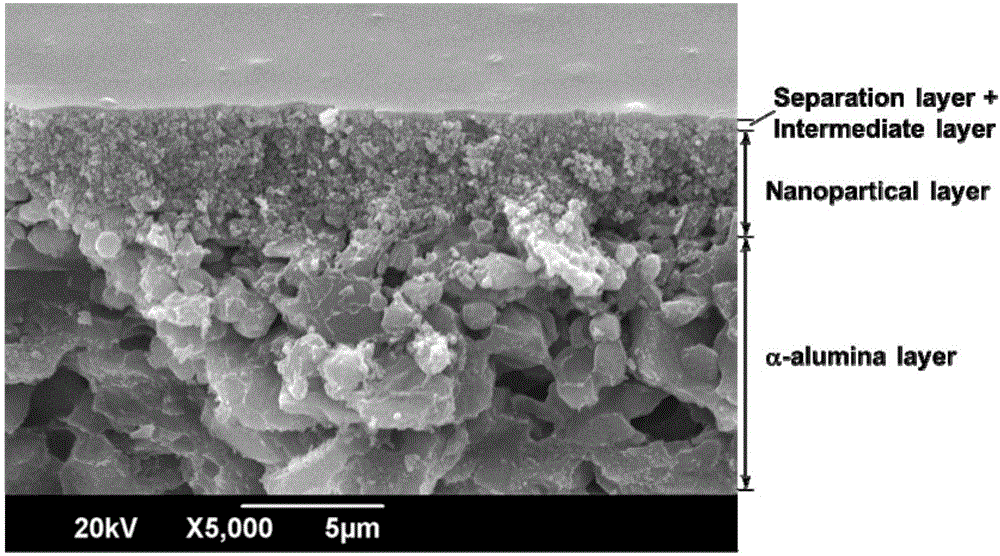

[0034] (2) α-Al 2 o 3 The particles are fully dispersed in a silica-zirconia sol with a mass fraction of 2% (in the sol, the molar ratio of silica to zirconia is 1:1), and the silica-zirconia sol and α-Al 2 o 3 The mass ratio of the particles was 10:1, and then the resulting mixed sol was coated on α-Al 2 o 3 Place the ceramic membrane in a tube furnace at 550°C for 30 minutes and repeat the process of "coating and calcination" 4 times to obtain the particle layer of the membrane;

[0035] (3) the α-Al coated with the particle layer obtained in step (2) 2 o 3 After the ceramic diaphragm was baked at 200°C for 10 minutes, a silica-zirconia sol with a mass...

Embodiment 2

[0039] (1) Add BTESE to absolute ethanol, then add deionized water drop by drop under stirring conditions, and finally add hydrochloric acid dropwise, the molar ratio of hydrogen chloride in BTESE, deionized water, and hydrochloric acid is 1:60:0.2, 40°C Stir in a water bath for 2 hours to obtain an organosilicon sol;

[0040] (2) α-Al 2 o 3 The particles are fully dispersed in a silica-zirconia sol with a mass fraction of 2% (in the sol, the molar ratio of silica to zirconia is 1:1), and the silica-zirconia sol and α-Al 2 o 3 The mass ratio of the particles was 10:1, and then the resulting mixed sol was coated on α-Al 2 o 3 Place the ceramic membrane in a tube furnace at 550°C for 30 minutes and repeat the process of "coating and calcination" 4 times to obtain the particle layer of the membrane;

[0041] (3) the α-Al coated with the particle layer obtained in step (2) 2 o 3 After the ceramic diaphragm was baked at 200°C for 10 minutes, a silica-zirconia sol with a mass...

Embodiment 3

[0045] (1) Add BTESE to absolute ethanol, then add deionized water drop by drop under stirring conditions, and finally add hydrochloric acid dropwise, the molar ratio of hydrogen chloride in BTESE, deionized water, and hydrochloric acid is 1:60:0.2, 40°C Stir in a water bath for 2 hours to obtain an organosilicon sol;

[0046] (2) α-Al 2 o 3 The particles are fully dispersed in a silica-zirconia sol with a mass fraction of 2wt.% (in the sol, the molar ratio of silica to zirconia is 1:1), and the silica-zirconia sol and α-Al 2 o 3 The mass ratio of the particles was 10:1, and then the resulting mixed sol was coated on α-Al 2 o 3 Place the ceramic membrane in a tube furnace at 550°C for 30 minutes and repeat the process of "coating and calcination" 4 times to obtain the particle layer of the membrane;

[0047] (3) the α-Al coated with the particle layer obtained in step (2) 2 o 3 After the ceramic diaphragm was baked at 200°C for 10 minutes, it was coated with 0.5wt.% silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com