A kind of electrolytic solution of aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor and electrolyte technology, applied in the field of aluminum electrolysis, can solve problems such as difficult to meet the use requirements, poor high-voltage resistance performance, and large capacitor loss, so as to suppress the increase of saturated vapor pressure, improve performance, and increase flashover voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

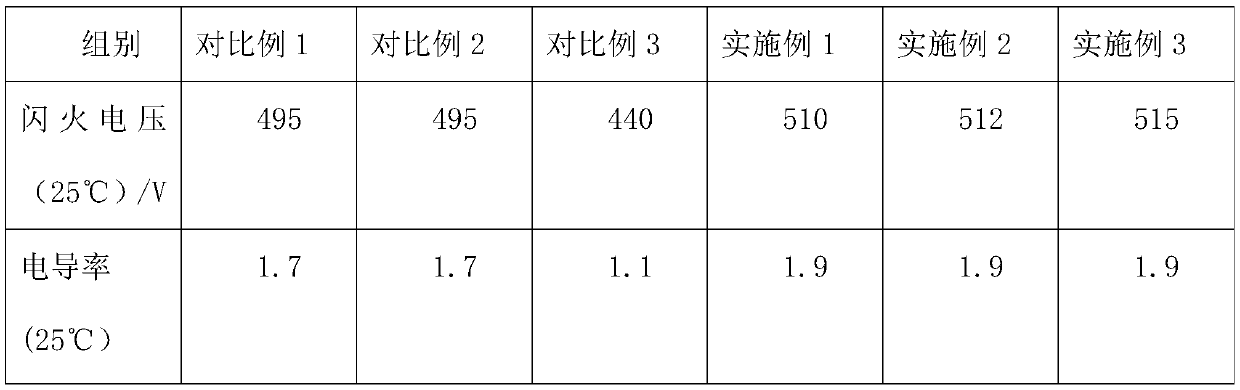

Examples

Embodiment 1

[0021] In the embodiment of the present invention, an electrolyte solution for aluminum electrolytic capacitors includes the following raw materials in parts by weight: 60 parts of ethylene glycol, 10 parts of diethylene glycol, 5 parts of solute, 1 part of flash fire enhancer, 1 part of stabilizer, 0.5 part of mannitol, 0.5 part of hydrogen remover, and 1 part of quercetin.

[0022] Wherein, the solute is boric acid, borate, sebacic acid, and branched-chain carboxylic acid dicarboxylic acid mixed according to a mass ratio of 2:1:1:1.

[0023] The flash fire enhancer is a mixture of tartaric acid, citric acid and polyvinyl alcohol in a mass ratio of 1:1:1.

[0024] The stabilizer is mixed with dextol, sorbitol and xylitol in a mass ratio of 1:2:1.

[0025] Described hydrogen remover is nitrobenzoic acid.

[0026] In this embodiment, the preparation method of the aluminum electrolytic capacitor electrolyte has the following steps:

[0027] 1) take each raw material by propor...

Embodiment 2

[0032] In the embodiment of the present invention, an electrolyte solution for aluminum electrolytic capacitors includes the following raw materials in parts by weight: 65 parts of ethylene glycol, 12 parts of diethylene glycol, 8 parts of solute, 2 parts of flash enhancer, 1.5 parts of stabilizer, 1 part of mannitol, 0.8 parts of hydrogen remover, and 1.5 parts of quercetin.

[0033] Wherein, the solute is mixed with ammonium hydrogen azelate, benzoic acid, and benzoate in a mass ratio of 1:1:2.

[0034] The flash fire enhancer is a mixture of polyethylene glycol, ammonium polyacrylate and polyglycerol in a mass ratio of 1:1:1.

[0035] The stabilizer is mixed with sucrose and vitamin C in a mass ratio of 1:1.

[0036] The hydrogen remover is p-nitroacetophenone.

[0037] In this embodiment, the preparation method of the aluminum electrolytic capacitor electrolyte has the following steps:

[0038] 1) take each raw material by proportioning;

[0039] 2) Add ethylene glycol...

Embodiment 3

[0043] In the embodiment of the present invention, an electrolyte solution for aluminum electrolytic capacitors includes the following raw materials in parts by weight: 70 parts of ethylene glycol, 13 parts of diethylene glycol, 10 parts of solute, 3 parts of flash enhancer, 2 parts of stabilizer, 1.5 parts of mannitol, 1 part of hydrogen remover, 2 parts of quercetin.

[0044] Wherein, the solute is a mixture of boric acid, borate, and benzoate in a mass ratio of 1:1:1.

[0045] The flash fire enhancer is a mixture of tartaric acid, citric acid and polyglycerol in a mass ratio of 1:2:1.

[0046] The stabilizer is mixed with dextol, sorbitol, xylitol and vitamin C in a mass ratio of 1:2:1:1.

[0047] The hydrogen remover is p-nitroacetophenone.

[0048] In this embodiment, the preparation method of the aluminum electrolytic capacitor electrolyte has the following steps:

[0049] 1) take each raw material by proportioning;

[0050] 2) Add ethylene glycol, diethylene glycol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com