Multilayer disc type centrifugation and gravity film forming and differential speed pressure reduction low-temperature evaporation device

A technology of differential decompression and low-temperature evaporation, which is applied in the direction of evaporation, separation methods, chemical instruments and methods, etc., and can solve the problems of insufficient evaporation of volatile components and affecting the evaporation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

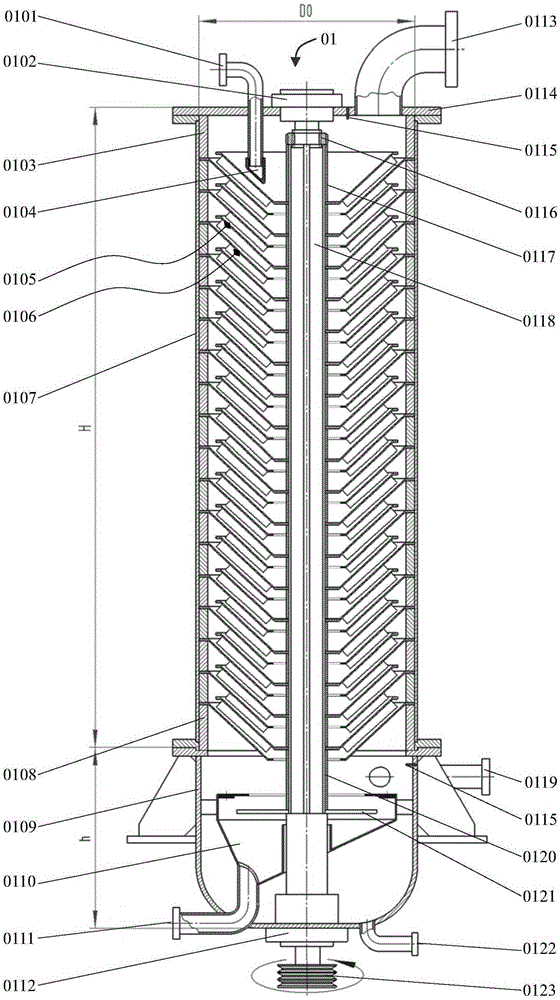

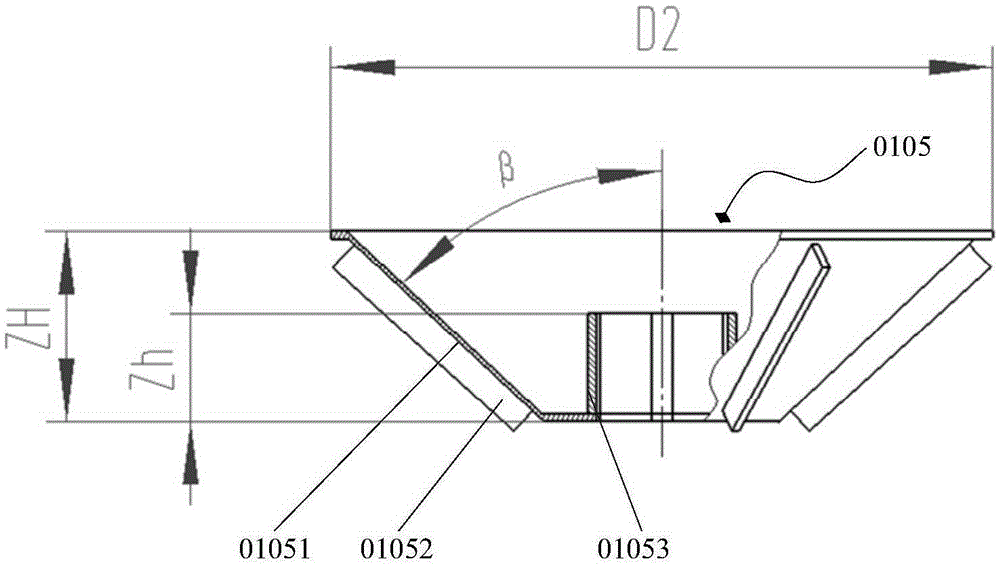

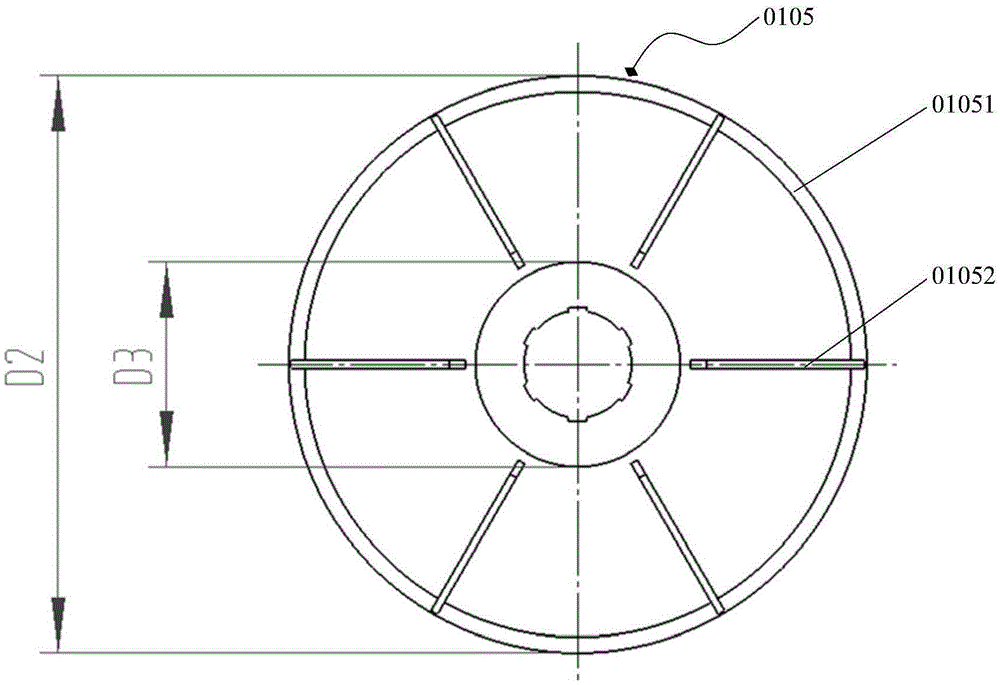

[0051] Such as figure 1 As shown, the present invention provides a low-temperature evaporation device 01 of multi-layer disc centrifugal and gravity film forming and differential decompression. Liquid nozzle 0104, rotary conical disc assembly 0105, fixed conical disc assembly 0106, cylinder 0107, lower positioning fixed conical disc 0108, machine base cylinder 0109, concentrate collecting bucket 0110, concentrate discharge Connecting pipe 0111, lower bearing assembly 0112, evaporated gas outlet connecting pipe 0113, cylinder upper cover 0114, temperature sensor 0115, tightening round nut 0116, upper positioning bushing 0117, central shaft 0118, hot air inlet connecting pipe 0119, lower positioning bushing 0120, concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com