Method for preparing oligo xylose in high purity by using stalk as raw material, and using technique of enzyme and membrane

A high-purity technology of xylooligosaccharides, which is applied in the field of food biochemical industry, can solve the problems of high loss of xylooligosaccharides, achieve simple processes, improve market competitiveness, and accelerate national economic development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: enzymatic hydrolysis process.

[0036] Blast the straw, add 5-15 times of water, mix well, adjust the pH to 4-8, the temperature is 40-60°C, add Aspergillus niger xylanase at a ratio of 50-300U / g dry basis, stir for 8-24h, Centrifuge or filter to obtain supernatant. The main evaluation index is the change of total sugar and reducing sugar content.

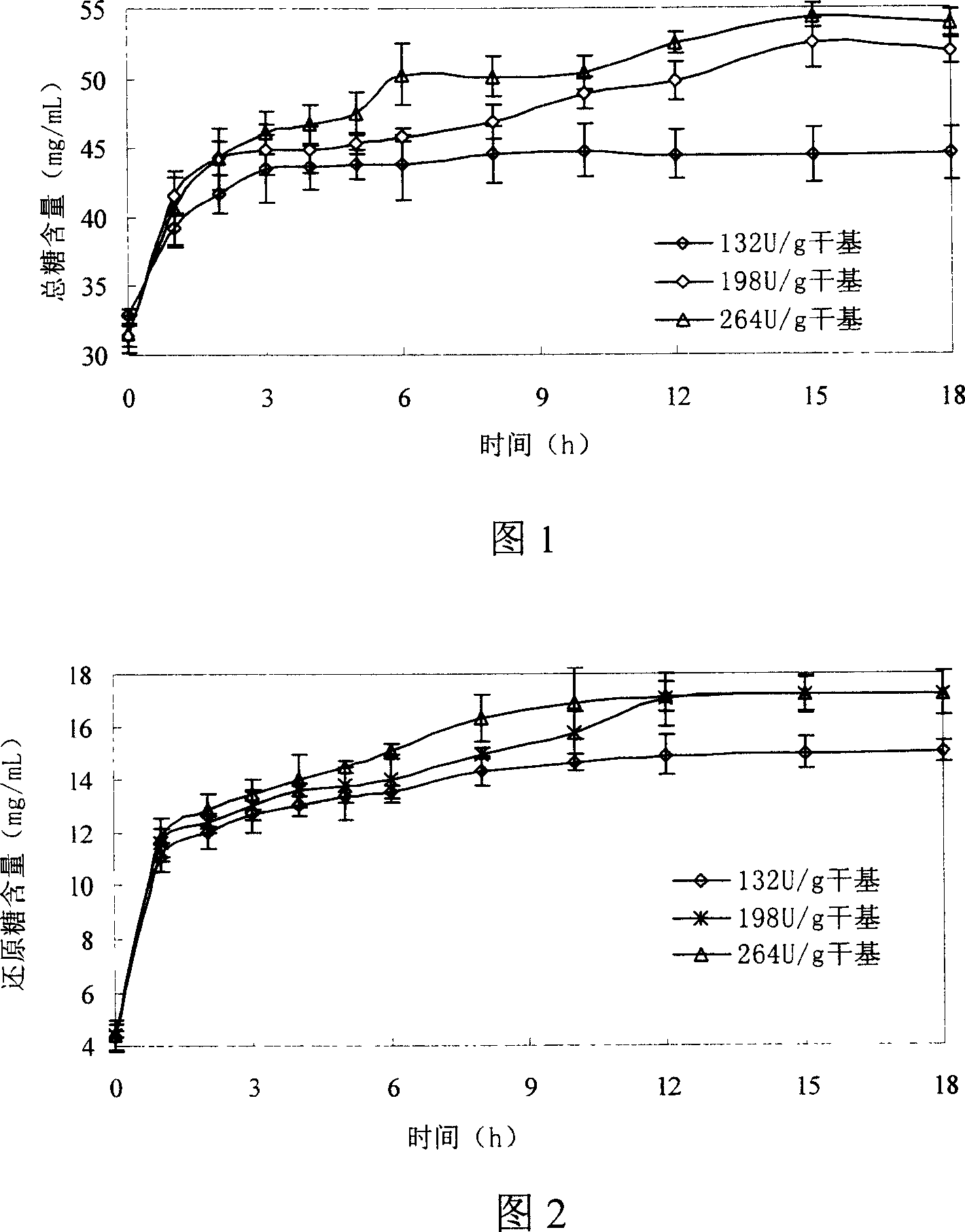

[0037] Figure 1 and Figure 2 show that the temperature is 53°C, the pH is 6.0, the amount of enzyme added is 132, 198, and 264 U / g dry basis when adding 8 times of water, and the enzyme hydrolysis time is 1, 2, 3, 4, 5, 6, 8, 10, 12, 15 and 18h, the change of total sugar and reducing sugar content. Both total sugar and reducing sugar increased gradually with time, but the rate of increase decreased gradually. The amount of enzyme added has a certain impact on the reaction. The higher the amount of enzyme added, the faster the hydrolysis rate, the higher the proportion of sugar increase in the same enzymatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com