Plastic bottle cutter

A bottle cutter and cutter technology, which is applied in metal processing and other directions, can solve the problem of low utilization rate of plastic bottles, and achieve the effects of improving utilization rate, simple operation and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

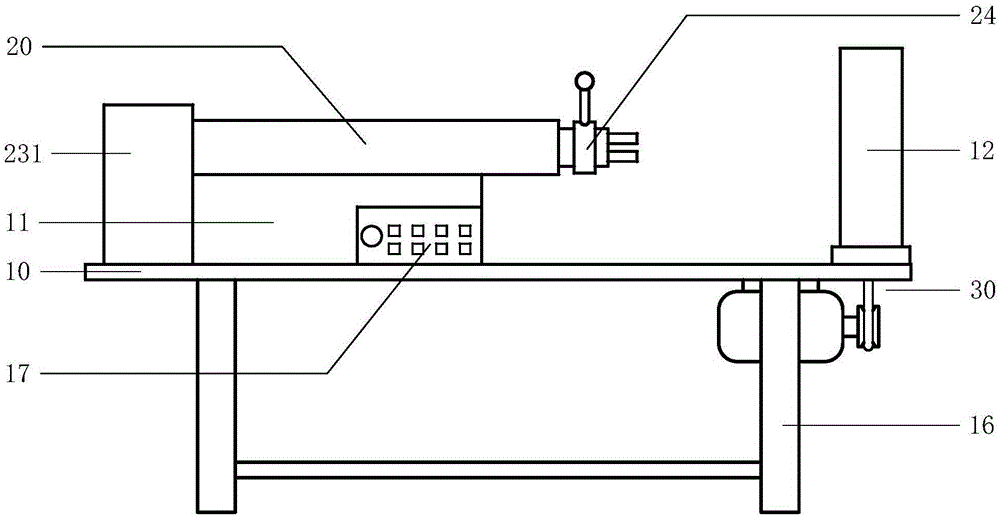

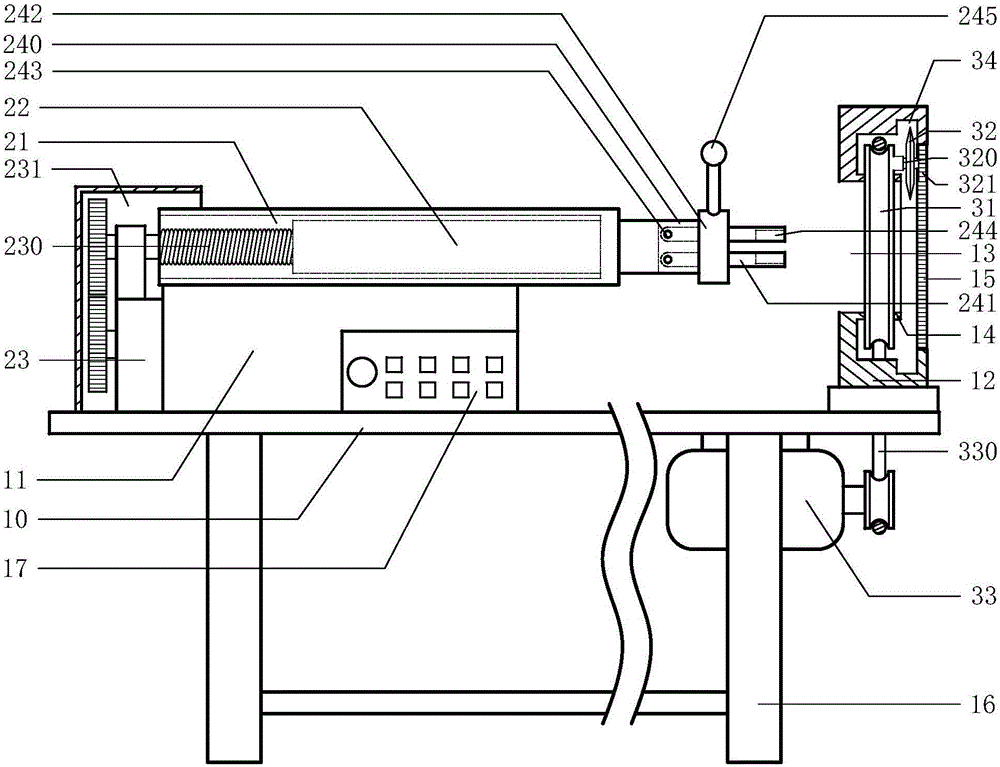

[0017] see figure 1 and combine figure 2 , the plastic bottle cutter of the present embodiment includes a work console 10, a horizontal bottle pusher 20 and a surrounding bottle cutter 30, one end of the work console 10 is provided with a push-pull frame 11, and the other end is provided with a cutting frame 12, The center of the cutting frame 12 is provided with a bottle cutting mouth 13, a runner shaft seat 14 is provided in the middle of the bottle cutting mouth 13, and a rotating toothed ring 15 is provided at the end of the bottle cutting mouth 13. The horizontal bottle pushing machine 20 is installed on the push-pull frame 11 and its structure includes positioning sleeve 21, telescopic ejector rod 22 and telescopic drive machine 23, is provided with opening and closing bottle mouth clip 24 at the end of telescopic ejector rod 22, and the surrounding bottle cutter 30 Including a wheel-shaped cutter frame 31, a surrounding cutter 32 and a wheel driver 33, the wheel-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com