A plastic bottle cutting strip utilization device

A technology for plastic bottles and cutting strips, applied in metal processing and other directions, can solve the problem of low recycling rate of plastic bottles, and achieve the effects of improving recycling rate, reasonable device structure and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

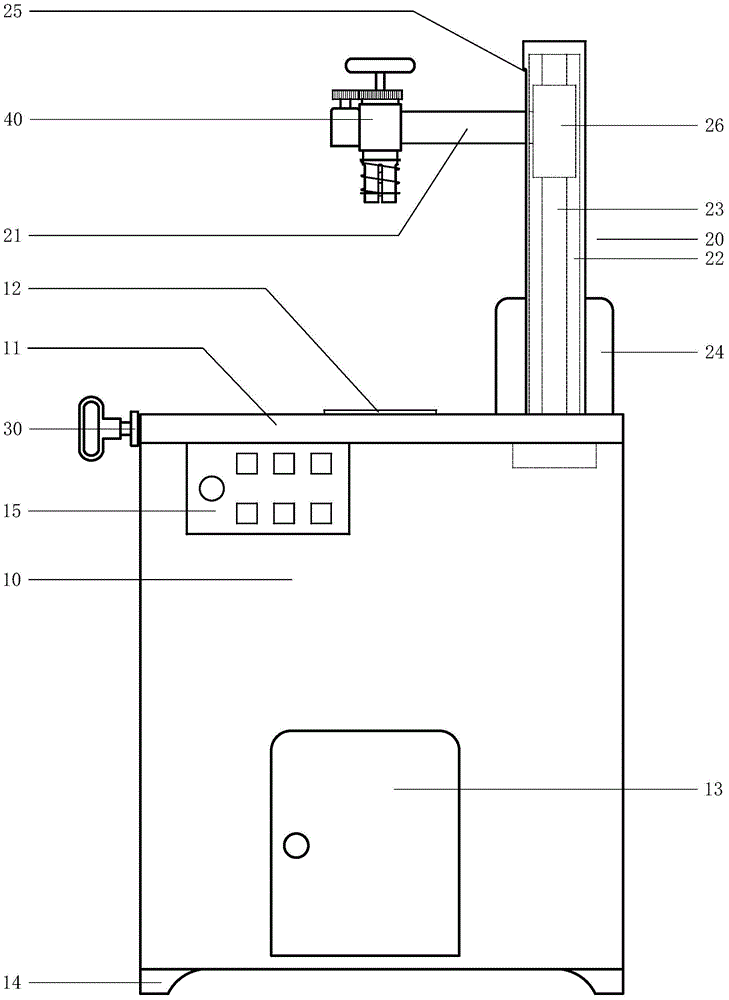

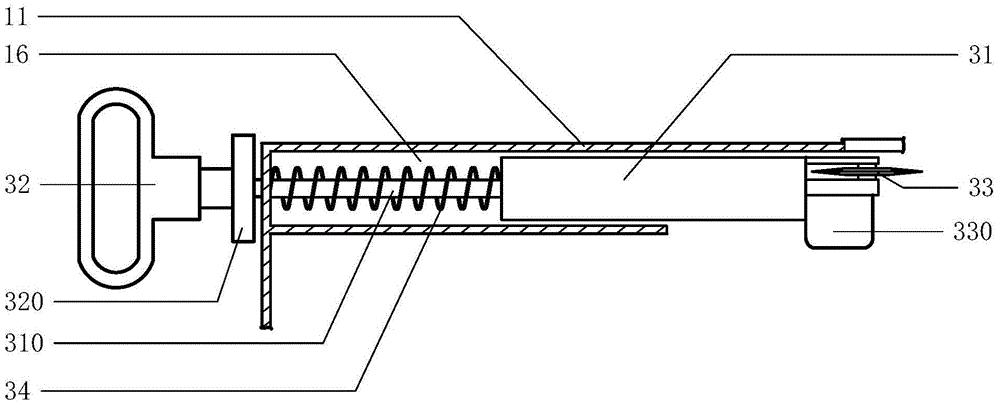

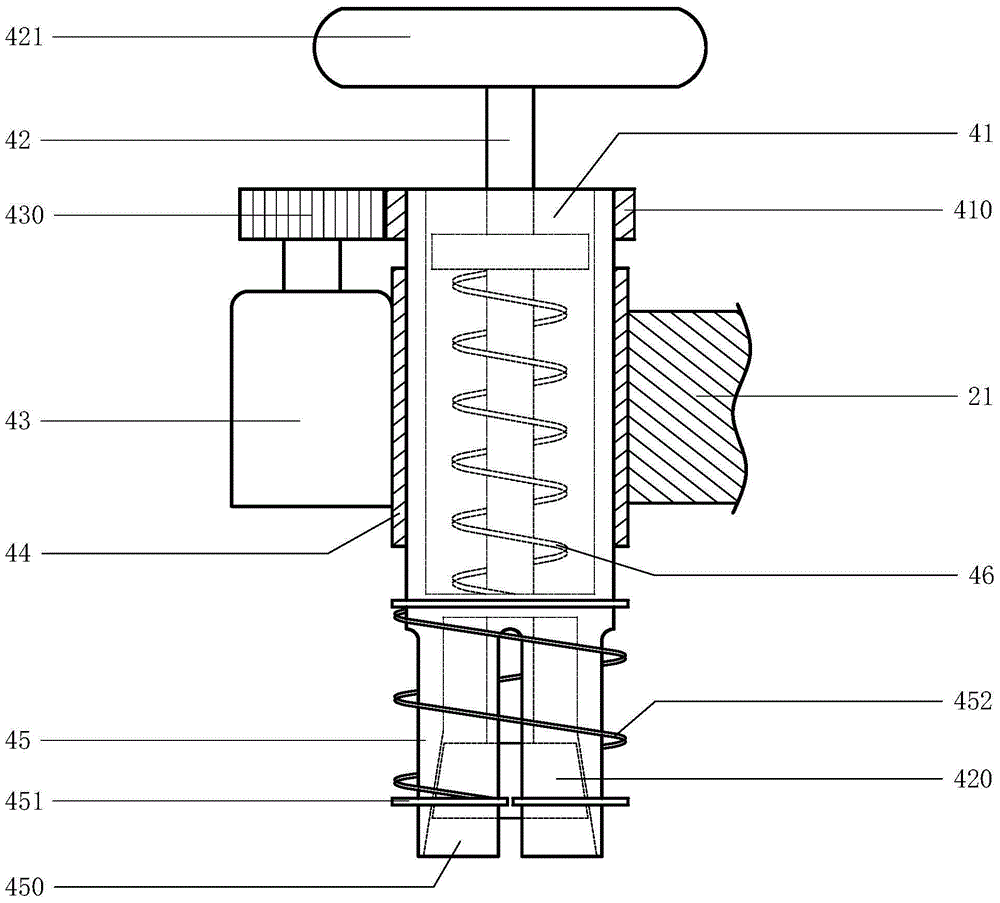

[0019] see figure 1 and combine figure 2 , 3 , the plastic bottle cutting strip utilizing device of the present embodiment comprises box-shaped frame 10 and vertical elevator 20, is provided with working platform 11 at box-shaped frame 10 tops, is provided with bottle body cutting mouth 12 in the middle part of working platform 11, so Described bottle body cutting mouth 12 is provided with clutch type cutter 30, and described clutch type cutter 30 comprises traverse cutter frame 31, push-pull handle 32 and wheel type cutter 33, and described traverse cutter frame 31 and working platform 11 is slidingly connected, the push-pull handle 32 is installed on the rear part of the traversing cutter frame 31, and the wheel-shaped cutter 33 is installed on the end of the traversing cutter frame 31 and can be pushed into the bottle body cutting port 12. The vertical The elevator 20 is installed on the top surface of the work platform 11 and is provided with a lifting arm 21, and a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com