A lifting type plastic bottle cutting machine

A plastic bottle and strip cutting machine technology, applied in plastic recycling, recycling technology, metal processing, etc., can solve the problem of low plastic bottle reuse rate, achieve the effect of increasing reuse rate, reducing environmental pollution, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

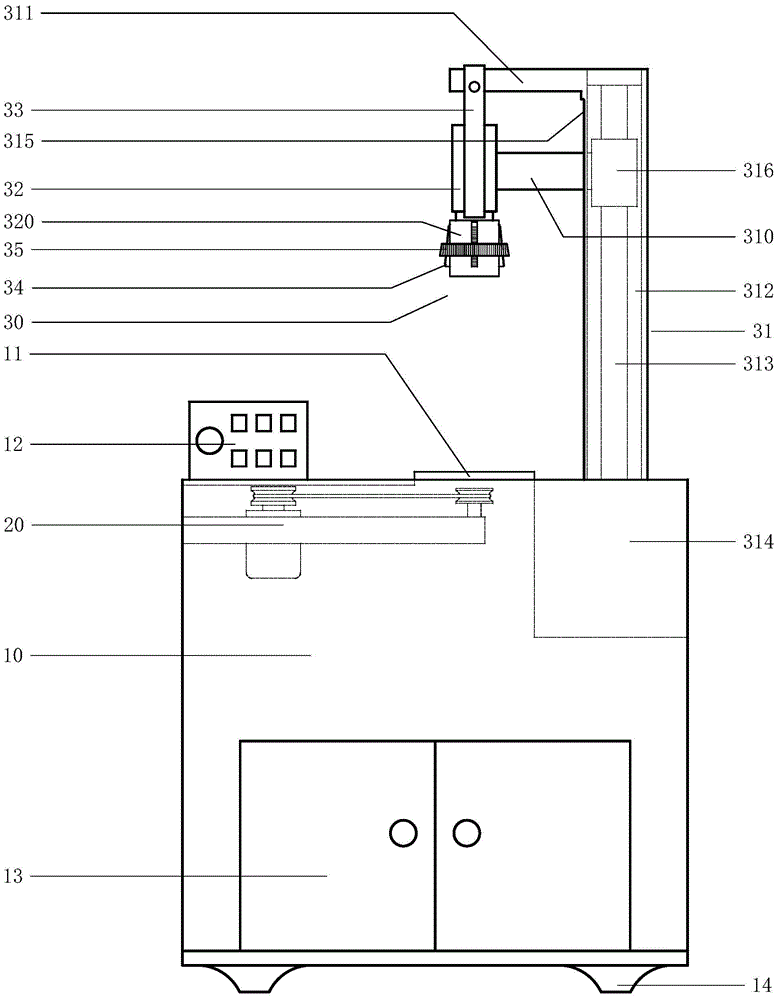

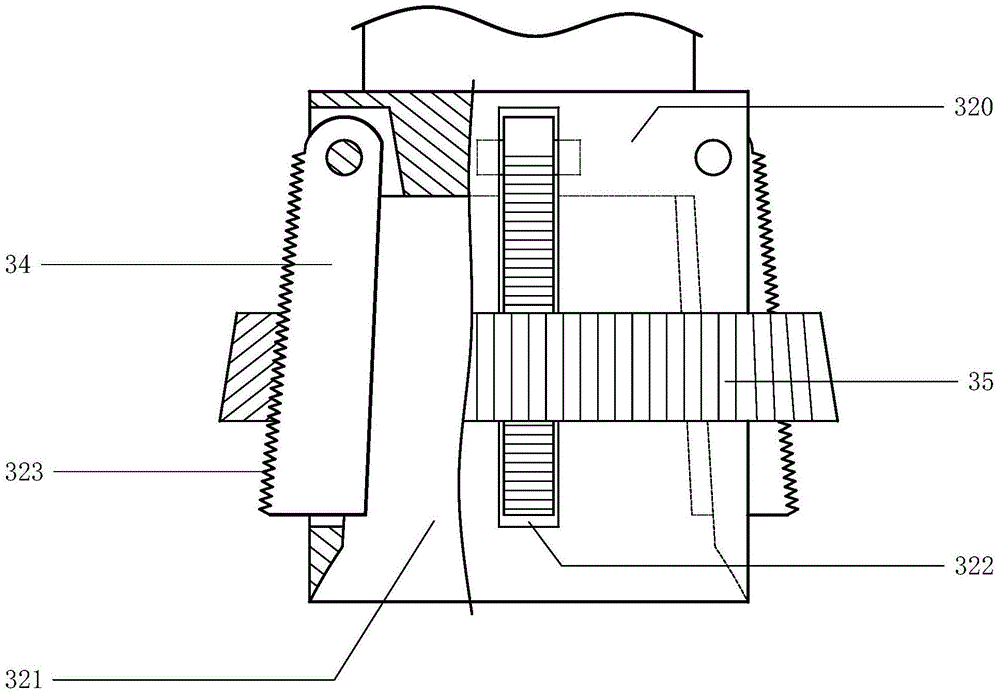

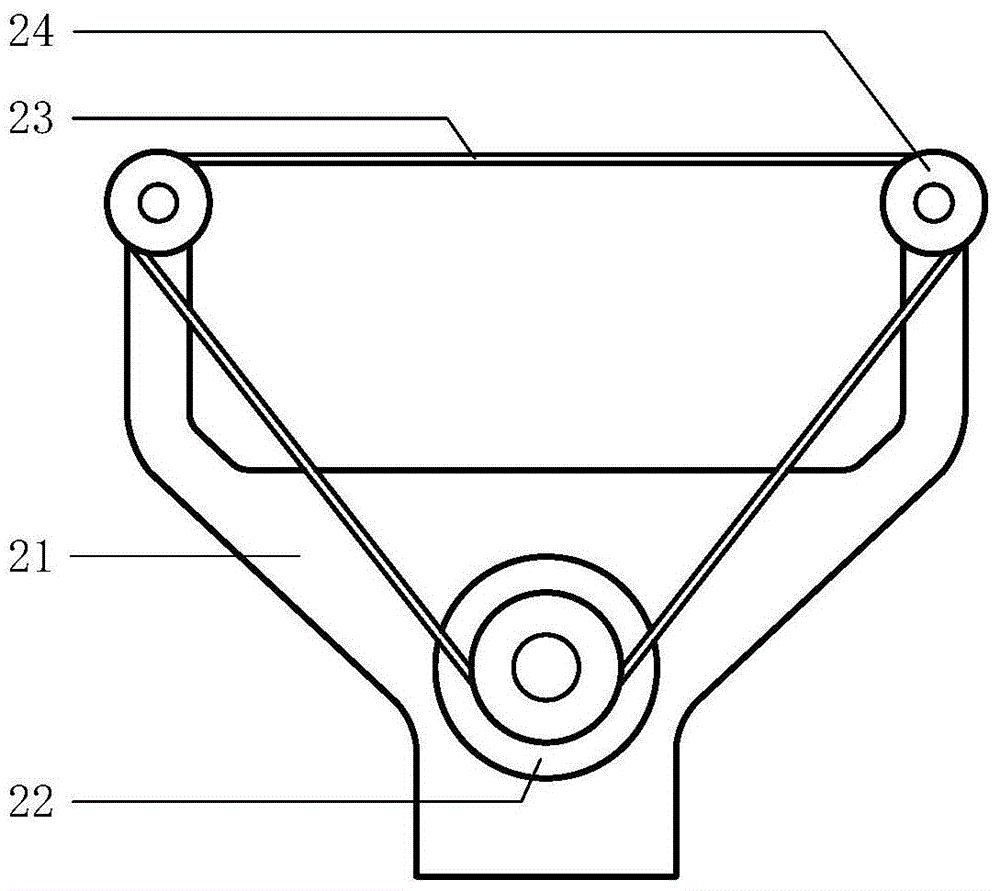

[0019] see figure 1 and combine figure 2 , 3 , 4. The lifting type plastic bottle cutting machine of the present embodiment comprises a box-shaped frame 10, a pull wire cutting bottle mechanism 20 and a lifting and pushing bottle mechanism 30, and the top of the box-shaped frame 10 is provided with a cutting box mouth 11 and an electromechanical console 12. The wire-drawing bottle cutting mechanism 20 is installed on the top of the inner chamber of the box-shaped frame 10 and its structure includes a wire-drawing cutter frame 21, a cutter driver 22 and a wire-type cutter 23. The wire-drawing cutter frame 21 is connected to the box Type frame 10 is connected, and described cutter driving machine 22 is installed on the backguy cutter frame 21, is provided with cutter drive wheel 24 on backguy cutter frame 21 and cutter driver 22, and described linear cutter 23 Set on the cutter driving wheel 24 and pass through the middle part of the cutting box mouth 11; the lifting and push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com