Advanced treatment process for fermented pharmaceutical waste water

A technology for advanced treatment of pharmaceutical wastewater, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. High problems, to achieve the effect of low operating cost, simple operation and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

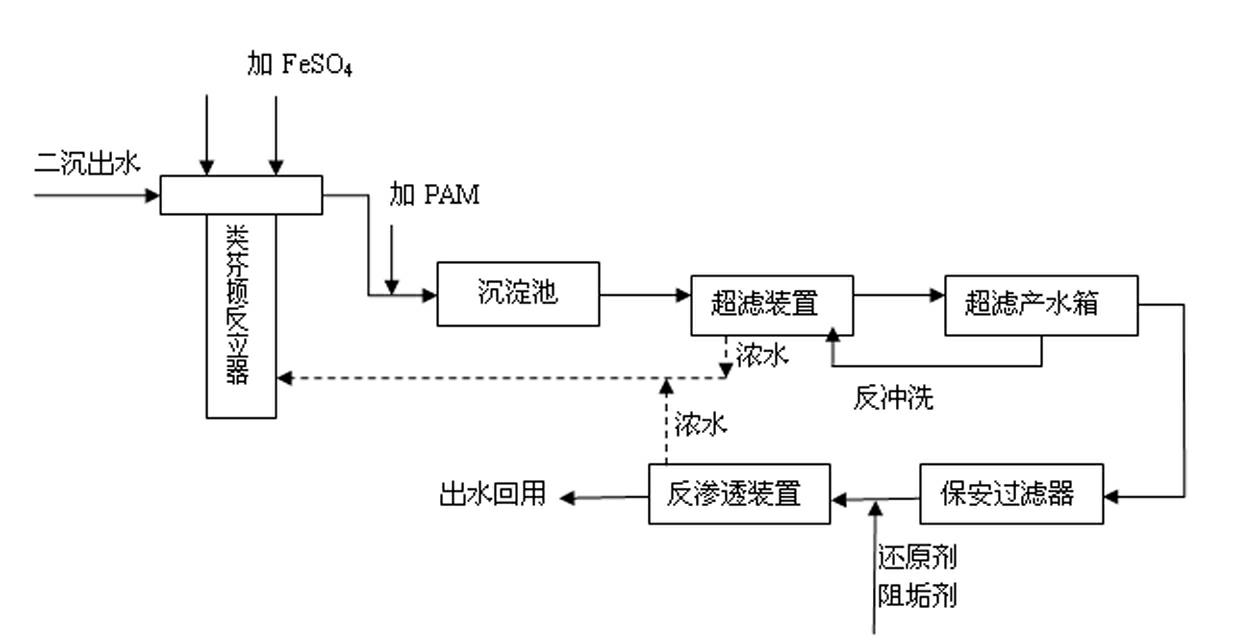

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] The advanced treatment process of fermentation pharmaceutical wastewater, the effluent of the biochemical treatment secondary sedimentation tank is directly pumped into the bottom of the Fenton-like reactor without adjusting the pH, and passes through the composite catalyst bed from bottom to top. The catalyst is uniform and granular, and the flow rate is controlled so that The expansion rate is around 30% to reduce loss. The organic matter in the wastewater was added to the FeSO 4 ·7H 2 O and H 2 o 2 Degradation is carried out under the joint action of 4 ·7H 2 O dosage is 0.2-0.4mmol / L, 30% (mass concentration) H 2 o 2 The amount added is 2-3mmol / L. In order to strengthen the removal of COD and blow off a small amount of unreacted H 2 o 2, Fenton-like reactor effluent is aerated, and the aeration time is 20 minutes.

[0031] The effluent from the Fent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com