Method for extracting tobacco volatile and semi-volatile aroma components

A technology for flavor components and extraction methods, which is applied in the field of separation and preparation of flavors and fragrances in tobacco, can solve the problems of incomplete range of measurable compounds, unsatisfactory adsorption efficiency of adsorbents, easy pollution of experimental environment, etc., and achieves clear characteristics of extracted products. , Easy to assemble, enhance the effect of taste and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

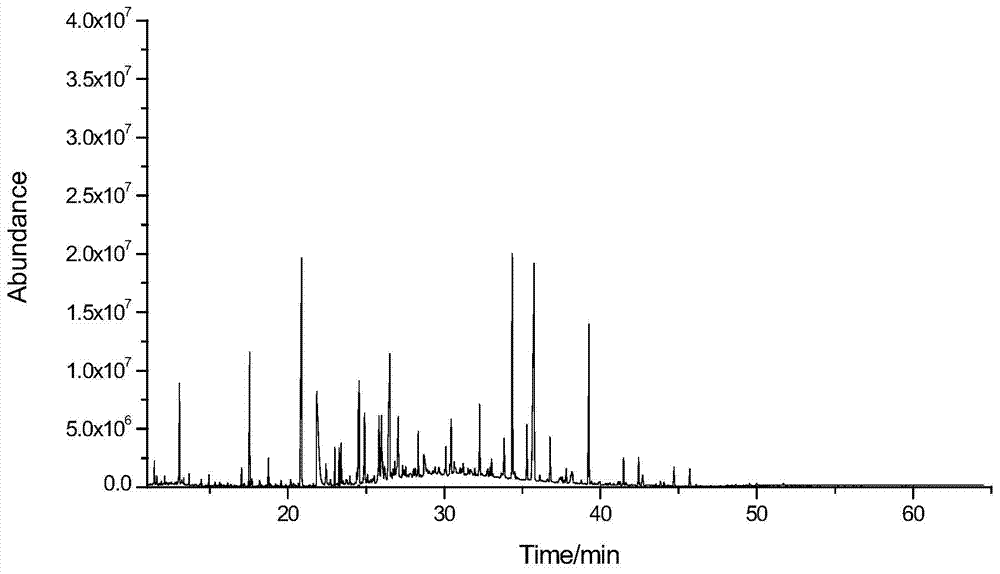

Embodiment 1

[0058] The following preparation method is used to extract the volatile and semi-volatile aroma components in No. 1 cigarette shredded tobacco (cigarette brand: Zhonghua), and the steps are as follows:

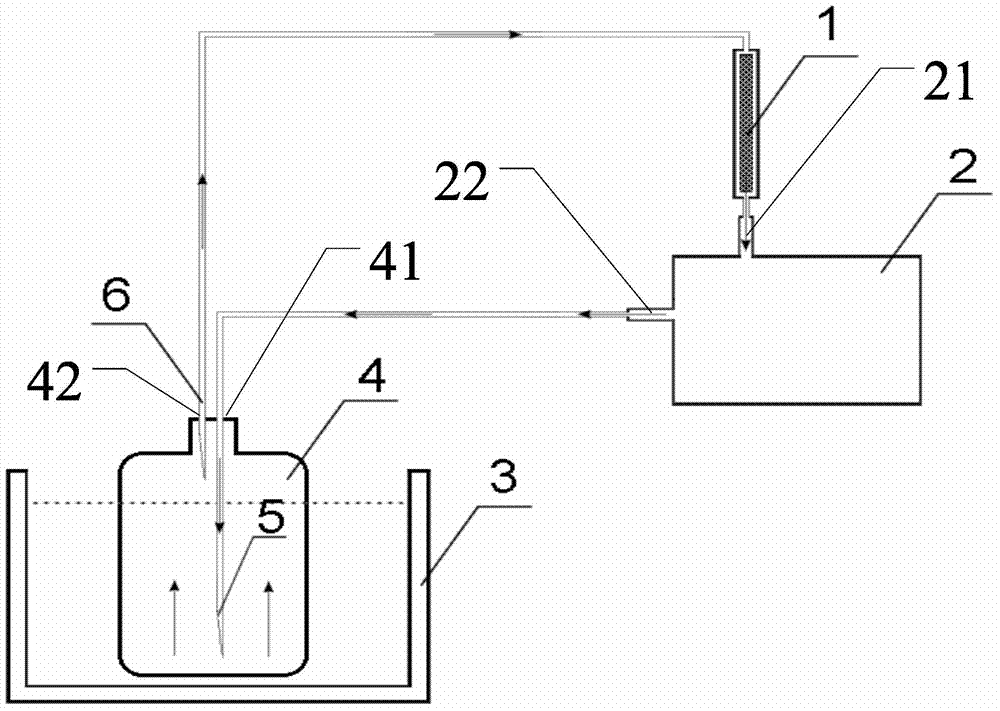

[0059] 1) After removing the filter tip and cigarette paper from the cigarette, obtain a cut tobacco sample, weigh 14g cut tobacco sample and put it into a headspace glass sample bottle with a sealed septum, put the sample bottle into a temperature-controlled water bath heating pot to heat at 40°C Equilibrate for 15 minutes;

[0060] 2) After equilibrium, the sample bottle is continuously heated by a temperature-controlled water bath heating pot, and an electric diaphragm air pump is used to prepare air. The outlet flow rate of the electric diaphragm air pump is 800ml / min, and the cut tobacco sample in the sample bottle is purged for 24 hours;

[0061] 3) Use activated carbon trapping tubes to catch and purge the air gained, and the activated carbon trapping tubes are filled w...

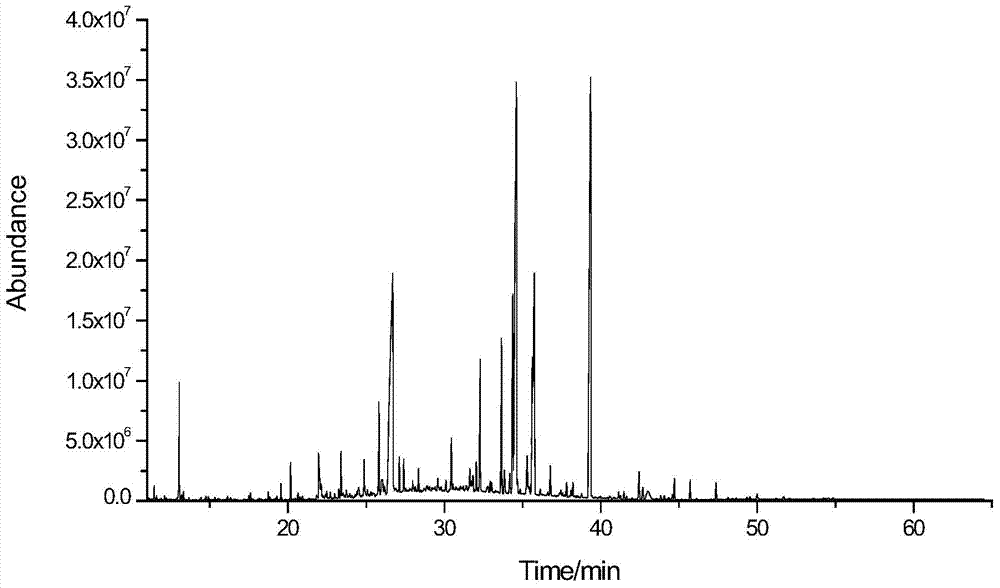

Embodiment 2

[0076] The following preparation method is used to extract the volatile and semi-volatile aroma components in No. 2 cigarette shredded tobacco (cigarette brand: Furongwang), and the steps are as follows:

[0077] 1) After removing the filter tip and cigarette paper from the cigarette, obtain a cut tobacco sample, weigh 14g cut tobacco sample and put it into a headspace glass sample bottle with a sealed septum, put the sample bottle into a temperature-controlled water bath heating pot to heat at 40°C Equilibrate for 15 minutes;

[0078] 2) After equilibrium, the sample bottle is continuously heated by a temperature-controlled water bath heating pot, and an electric diaphragm air pump is used to prepare air. The outlet flow rate of the electric diaphragm air pump is 800ml / min, and the cut tobacco sample in the sample bottle is purged for 24 hours;

[0079] 3) Use activated carbon trapping tubes to catch and purge the air gained, and the activated carbon trapping tubes are filled...

Embodiment 3

[0089] The following preparation method is used to extract the volatile and semi-volatile aroma components in No. 3 cigarette shredded tobacco (cigarette brand: Yunyan), and the steps are as follows:

[0090] 1) After removing the filter tip and cigarette paper from the cigarette, obtain a cut tobacco sample, weigh 14g cut tobacco sample and put it into a headspace glass sample bottle with a sealed septum, put the sample bottle into a temperature-controlled water bath heating pot to heat at 40°C Equilibrate for 15 minutes;

[0091] 2) After equilibrium, the sample bottle is continuously heated by a temperature-controlled water bath heating pot, and an electric diaphragm air pump is used to prepare air. The outlet flow rate of the electric diaphragm air pump is 800ml / min, and the cut tobacco sample in the sample bottle is purged for 24 hours;

[0092] 3) Use activated carbon trapping tubes to catch and purge the air gained, and the activated carbon trapping tubes are filled wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com