Process and device for extracting battery grade lithium from brine

A battery-grade, brine technology, applied in lithium carbonate;/acid carbonate and other directions, can solve the problems of large amount of reagents, long time consumption, low yield, etc., to improve product yield and product quality, The effect of increasing the concentration ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

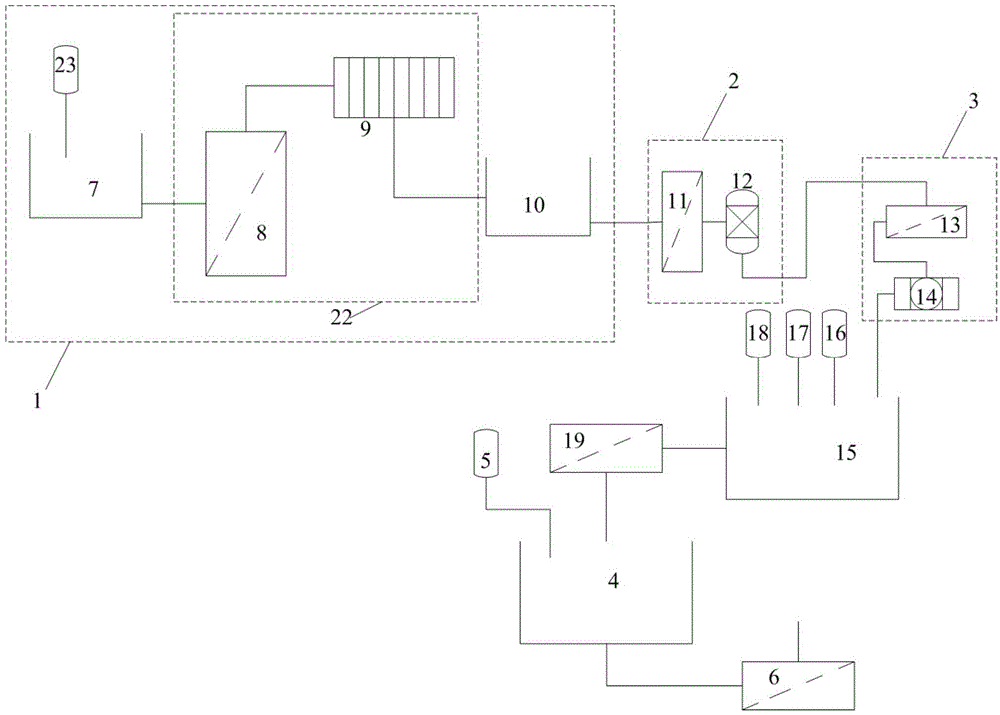

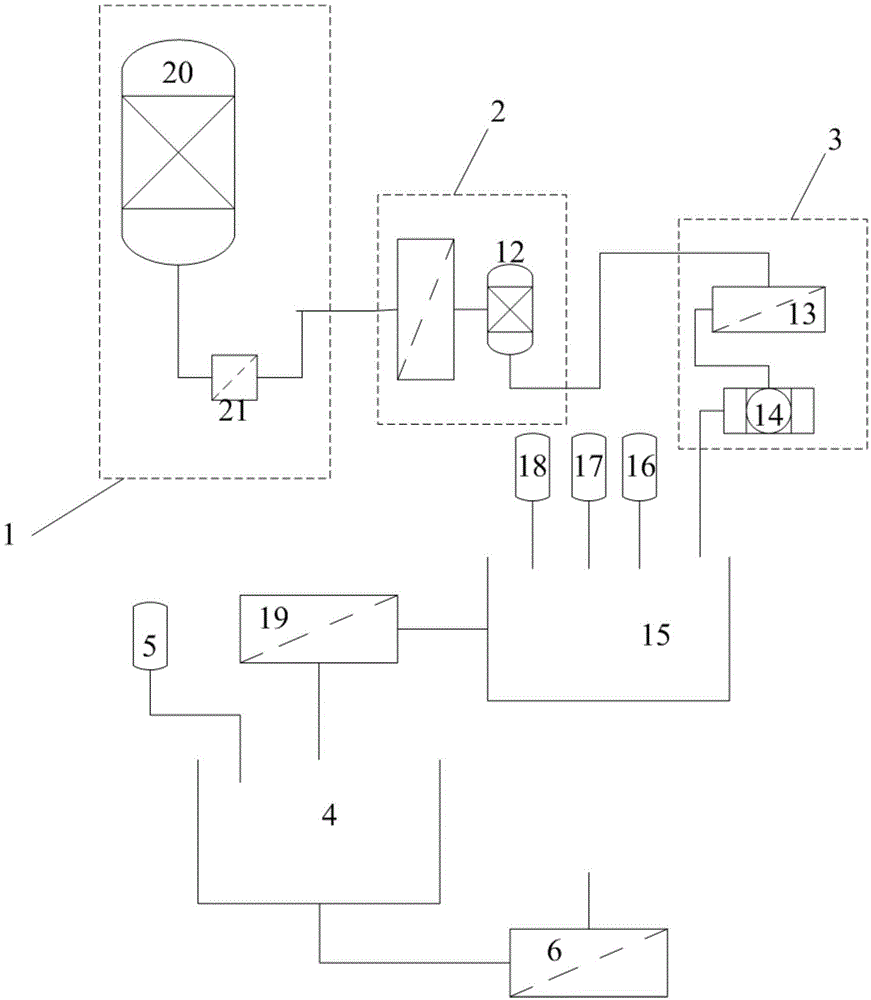

Method used

Image

Examples

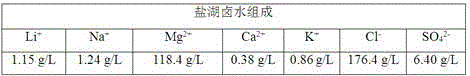

Embodiment 1

[0111] 100gFeSO 4 The ion sieve lithium adsorbent was loaded into the packed column, and the salt lake brine was sent into the adsorbent bed at a rate of 3 BV / h. After 2 hours, the adsorption saturation was reached, and Li +The concentration of lithium is no longer reduced; use phosphoric acid solution for desorption, the pH of the phosphoric acid solution is controlled at about 1, the flow rate of the desorbent is 2 BV / h, and the desorption is completed after about 3 hours, and the lithium desorption solution is then removed by weak acid cation exchange resin D113 For a small amount of magnesium in the desorption solution, the flow rate of the desorption solution is controlled at 5 BV / h, and then the concentration of lithium ions in the treated desorption solution is concentrated to about 20g / L with a reverse osmosis membrane, and the concentration temperature of the reverse osmosis is controlled at 30°C. The operating pressure is 0.15Mpa, that is, lithium ions can be convert...

Embodiment 2

[0114] The difference from Example 1 is that the process of adsorption and desorption is to mix the adsorbent in brine, and then dehydrate the adsorbent through ceramic membrane filtration and plate-and-frame filtration before desorption. The specific steps are:

[0115] 100gFeSO 4 The ionic sieve adsorbent was added to 50L salt lake brine, heated and stirred, the temperature of the solution was controlled at 40°C, and stirred for 60 minutes, the Li in the brine + into the adsorbent, at this time the Li in the solution + The concentration is reduced to 1.07g / L, FeSO 4 The ion sieve adsorbent has an adsorption capacity of about 40 mg / g of Li, and then uses a ceramic membrane to concentrate and filter the mixed material liquid. The average pore size of the ceramic membrane is 5, 20, 50, 200, and 500 nm, and the filtration pressure is 0.2 MPa. The membrane surface flow rate is 3 m / s, the filtration temperature is 50°C, the backflush interval is 40min, and the backflush time is...

Embodiment 3

[0121] The difference from Example 2 is that after the desorption solution is obtained, magnesium and calcium ions are removed through a primary nanofiltration membrane. The specific steps are:

[0122] 100gFeSO 4 The ionic sieve adsorbent was added to 50L salt lake brine, heated and stirred, the temperature of the solution was controlled at 40°C, and stirred for 60 minutes, the Li in the brine + into the adsorbent, at this time the Li in the solution + The concentration is reduced to 1.07g / L, FeSO 4 The ion sieve adsorbent has an adsorption capacity of about 40 mg / g of Li, and then uses a ceramic membrane to concentrate and filter the mixed material liquid. The temperature is 50°C, the backflush interval is 40min, and the backflush time is 10s; the ceramic membrane filter concentrate is filtered through plate and frame to remove most of the impurities and water in the concentrate, and the adsorbent filter cake that has adsorbed lithium is obtained, and the press filter Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com