Method for realizing approximate zero discharge of high-fluorine-content and high-nitrogen-content battery production waste water in photovoltaic industry

A production wastewater, zero-discharge technology, applied in general water supply conservation, chemical instruments and methods, water pollutants, etc., can solve problems such as difficult normal operation of membrane equipment, calcium ion pollution, etc., to reduce costs, increase concentration multiples, reduce effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example (

[0038] Implementation case (using the method of the present invention for the production of high fluorine and nitrogen-containing batteries in the photovoltaic industry to approach zero discharge):

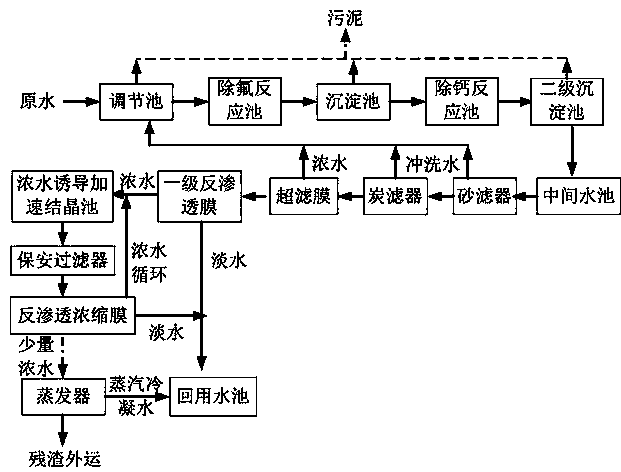

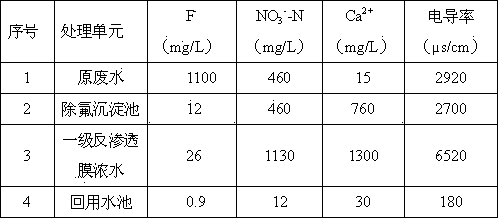

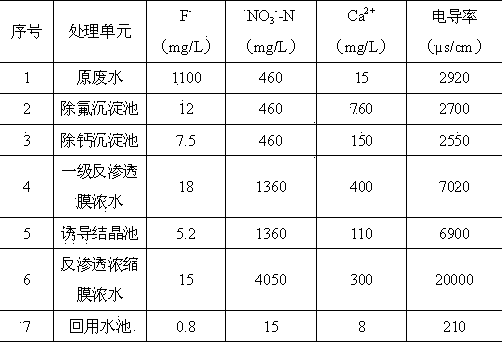

[0039] The production wastewater of high fluorine and nitrogen-containing batteries in a photovoltaic industry has the following water quality characteristics: NO 3 - -N 460 mg / L, F - 1100 mg / L, conductivity 2920μs / cm. The specific process of wastewater treatment is as follows: figure 1 As shown, firstly, the production wastewater with high fluorine and nitrogen content is sent to the adjustment tank for homogenization; then it enters the defluorination reaction tank, and calcium hydroxide is added to it to adjust the pH of the wastewater to 8.5, so that fluoride ions and calcium ions form calcium fluoride precipitation , and then add polyaluminum chloride and polyacrylamide in turn for coagulation, the effluent from the reaction tank enters the sedimentation tank, and the sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com