Bistable direct drive hardness tester spindle loading and unloading unit

An unloading unit, direct-drive technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of high manufacturing cost, unstable force application, enlarged lever mechanism, etc., and achieves good anti-vibration buffering effect. The effect of stable and accurate load and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

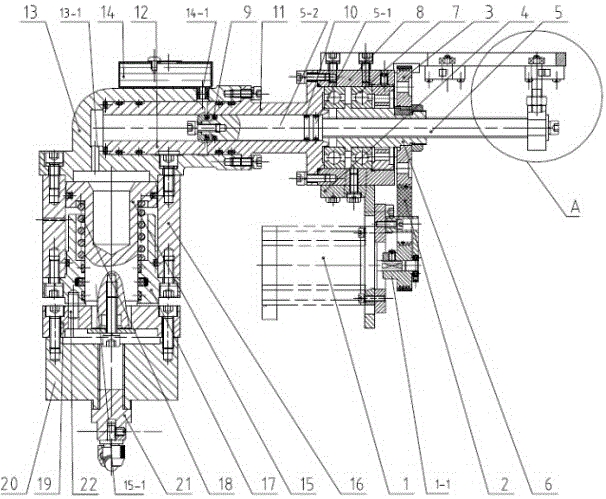

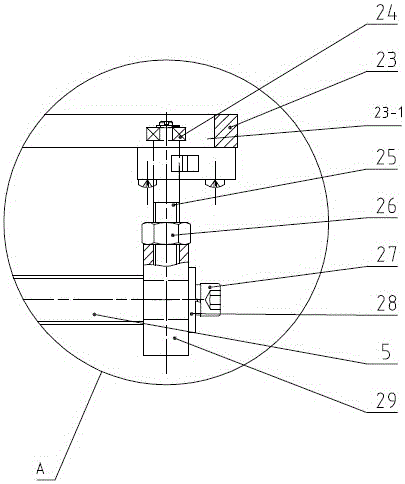

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] Such as figure 1 , figure 2 As shown, the present invention includes loading and unloading mechanism, main shaft mechanism, wherein:

[0036] (1) Loading and unloading mechanism: refer to figure 1 , figure 2 .

[0037] The function of the loading and unloading mechanism is to generate power and stably transmit the power to the small piston through the ball screw. Specifically, the rotary motion of the stepper motor is converted into the forward and backward linear movement of the ball screw and the small piston.

[0038] Such as figure 1 , figure 2As shown, the loading and unloading mechanism includes stepping drive mechanism, screw nut 6, ball screw 5, small piston 5-2, sealing ring I9, sealing ring II10, bearing I7, bearing sleeve 8, connecting sleeve 11, front sleeve 12 , elbow 13, guide anti-rotation mechanism an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com