Earth and rockfill dam inner deforming non-contact monitoring method

A deformation monitoring, non-contact technology, applied in the direction of measuring devices, instruments, etc., to achieve the effect of small construction interference, strong anti-rolling ability, and not easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

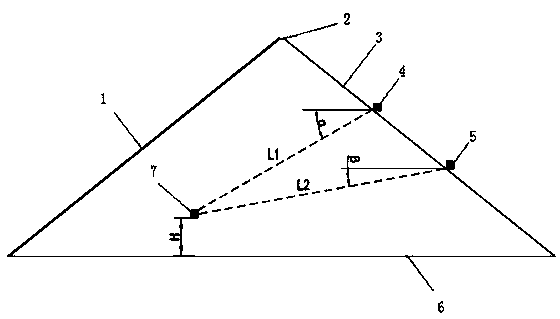

[0011] The non-contact monitoring method for monitoring the internal deformation of the earth-rockfill dam of the present invention is to bury the target measuring point 7 with a large difference in the material of the rockfill body inside the earth-rockfill dam body, and outside the rockfill body (such as the downstream dam surface) or the dam Install detection instruments in the inner corridor to detect the distance between the target measuring point and the detection instrument from different positions and angles. According to the known position of the detection instrument, the detection distance between the detection instrument and the target measurement point, and the distance between the detection distance and the horizontal The included angle determines the initial position of the target measuring point, and the position of the target measuring point is actually measured within a specified time interval. The difference between each measured position and the initial positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com