Triaxial sample preparation device for hammer-type rockfill materials and use method

A technology for triaxial samples and rockfill materials, which is applied in the field of triaxial test sample preparation devices for rockfill materials, can solve problems such as difficulty in accurate measurement, large density dispersion, poor sample uniformity, etc., and achieve positioning accuracy, test High sample uniformity, good effect of sample uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

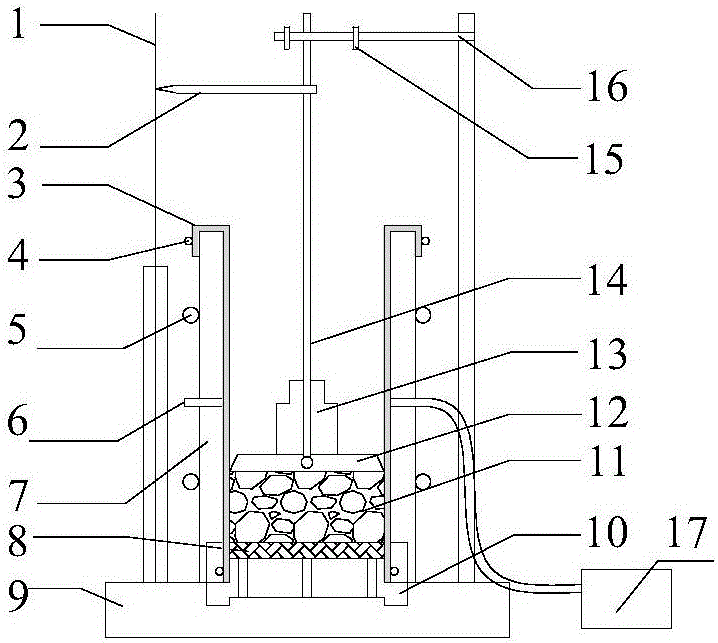

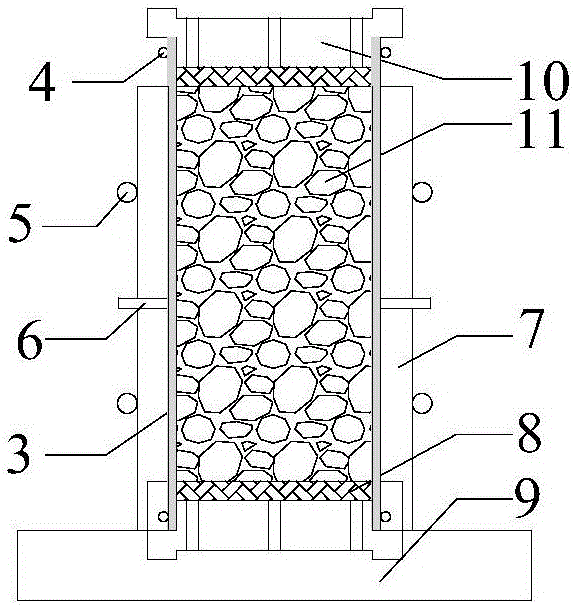

[0026] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

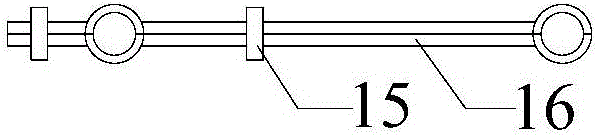

[0027] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown is a hammer-type rockfill material triaxial sample preparation device, including 1-test ruler, 2-measuring rod, 3-rubber film, 4-O-ring, 5-collar, 6-exhaust duct, 7-split mold, 8-permeable stone, 9-base, 10-permeable plate, 11-rock pile, 12-compacting backing plate, 13-compacting hammer, 14-compacting hammer guide rod, 15-U-shaped Buckle, 16-guide rod locator, 17-vacuum pump, 18-metal ball.

[0028] In the present invention, the sample preparation mechanism includes two split molds 7, the convex interface of the split mold 7 matches the size of the concave interface, and the split mold 7 is first formed by the convex and concave interfaces. sample preparation cylinder, and then use the collar 5 to seamlessly connect the two split molds 7; The diameter of the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com