Rockfill material triaxial test device

A triaxial test and rockfill material technology, which is applied in the field of rockfill triaxial test equipment, can solve the problems of sample disturbance, insufficient stroke, short stroke, etc., and achieve the effect of reducing energy consumption and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

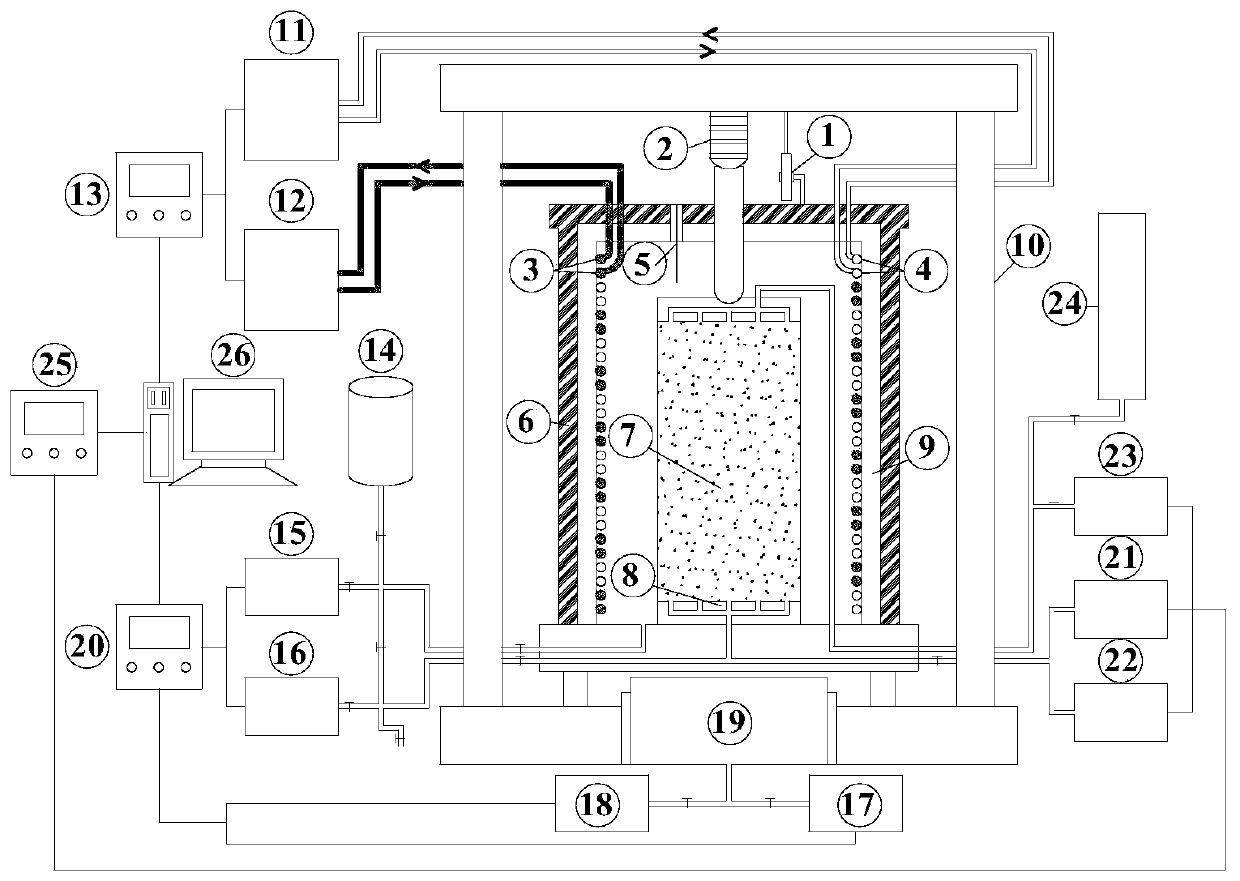

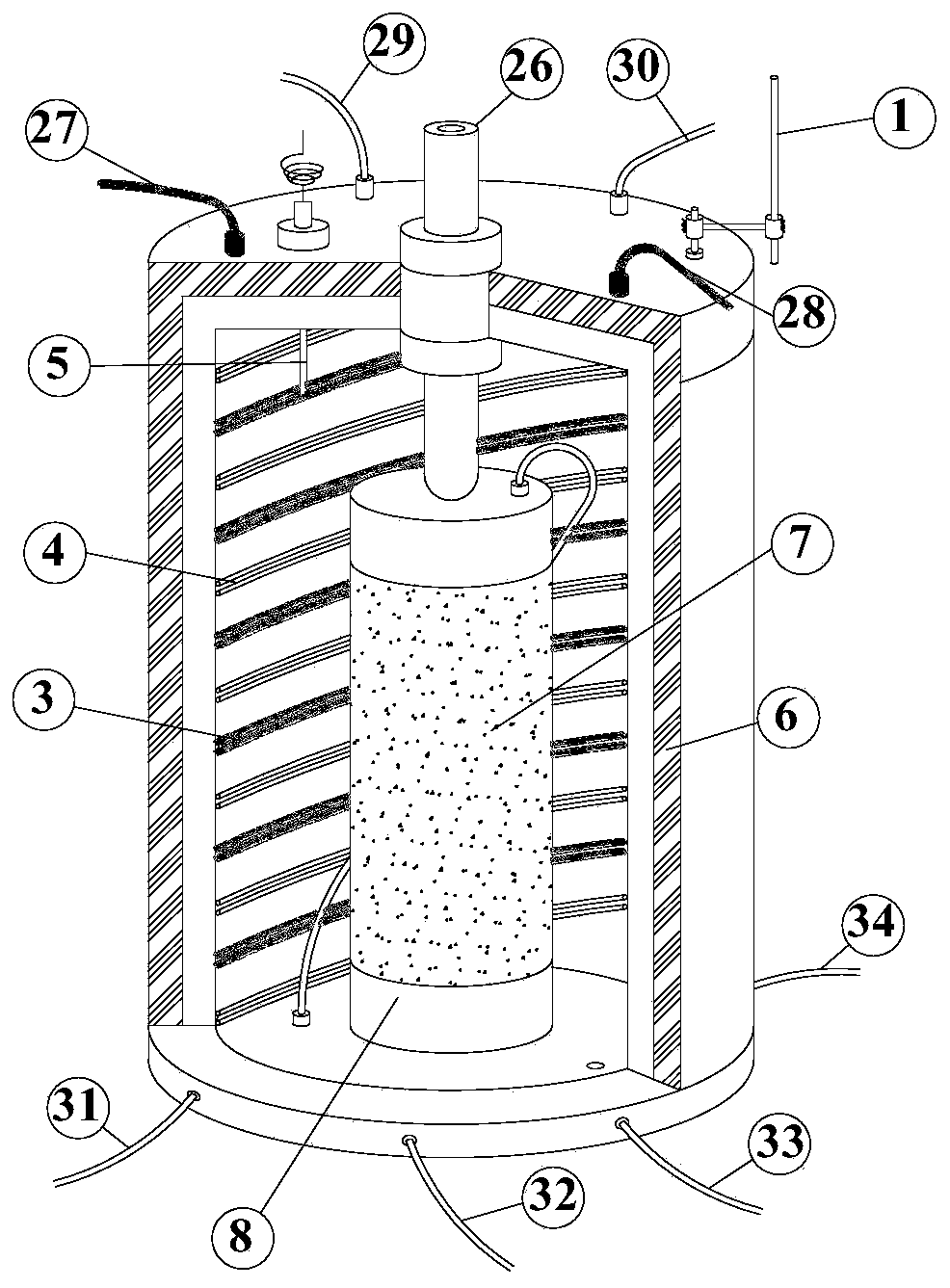

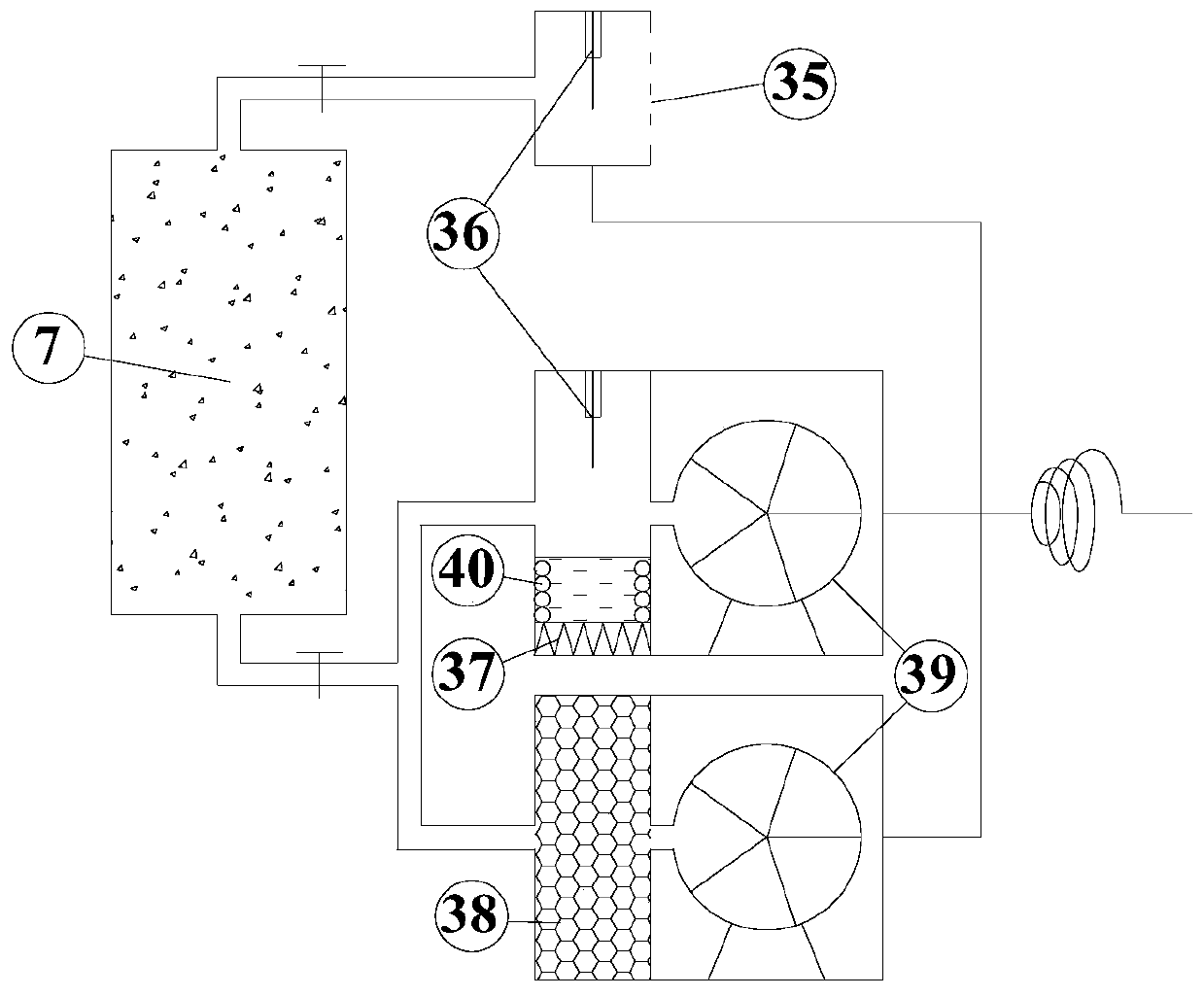

[0015] like figure 1 As shown, the rockfill material triaxial test device of the present invention includes a loading system, a temperature control system, a humidity control system, and a data acquisition and control system. Among them: 1 displacement sensor; 2 axial pressure sensor; 3 high temperature circulation pipe; 4 low temperature circulation pipe; 5 temperature sensor; 6 heat preservation cover; 7 sample; 8 permeable stone; 9 pressure cover; ;12 high temperature water bath box; 13 temperature controller; 14 water storage barrel; 15 confining pressure actuator; 16 hole pressure actuator; 17 hydraulic pump; 18 axial pressure actuator; 19 pressure cylinder; 20 pressure controller; 21 Humidifying device; 22 Drying device; 23 Relative humidity measuring device; 24 Body variable tube; 25 Relative humidity controller; 26 Computer; Liquid ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com