A kind of asphalt cohesion determination method

A measurement method and technology of cohesion, which is applied in the field of asphalt performance testing in highway engineering, can solve the problems of difficult and inaccurate determination of cohesion, achieve convenient evaluation, reduce measurement cost, and improve accuracy Effects of Sex and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

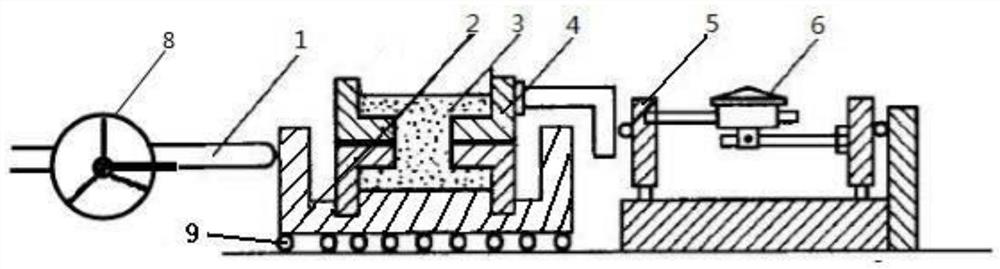

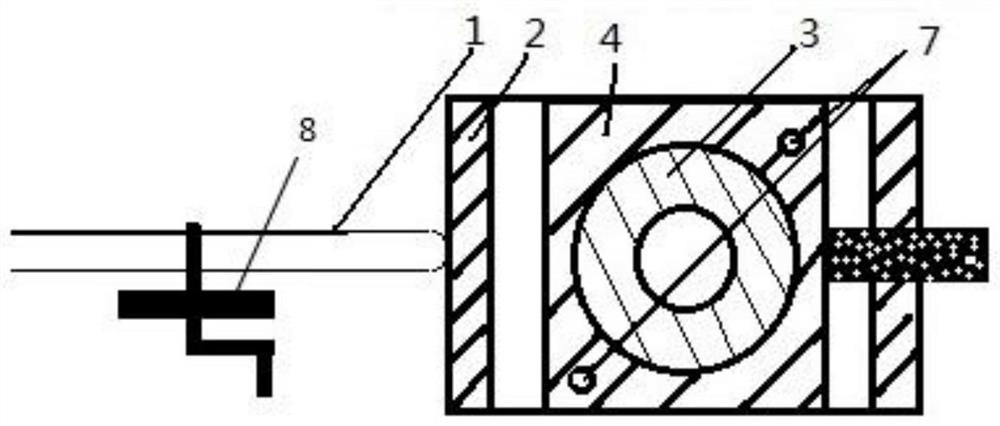

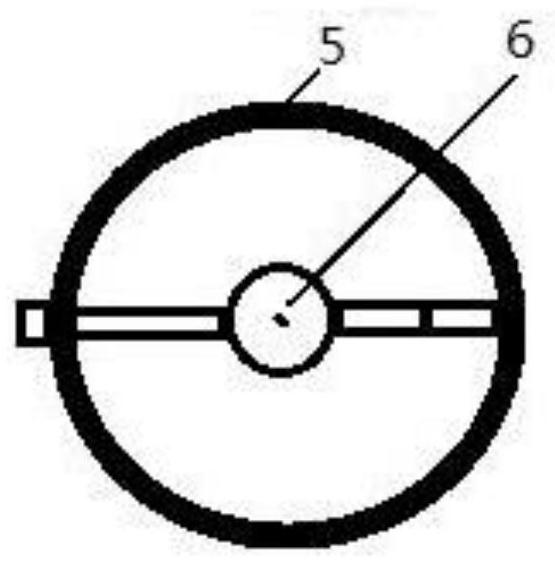

[0035] The method of the present embodiment comprises the following steps:

[0036] Step 1. Align the upper box 4 and the lower box 2 in the improved strain-controlled direct shear instrument and insert the fixed pin into the corresponding pin hole 7 to assemble the shear box, and then install the shear box on the inner wall and The bottom surface is coated with an asphalt release agent; the upper box 4 is provided with a round hole formed by a large-diameter round hole and a small-diameter round hole through which the longitudinal section is an inverted convex shape; the lower box 2 is provided with a round hole with a large diameter Holes and small-diameter round holes and blind holes with a convex longitudinal section; the inner diameters of the large round holes in the upper box 4 and the lower box 2 are both 40mm, and the height of the large round holes in the upper box 4 is 15mm. The height of the middle scale line is 10mm, the height of the large round hole in the lower...

Embodiment 2

[0042] The method of the present embodiment comprises the following steps:

[0043] Step 1. Align the upper box 4 and the lower box 2 in the improved strain-controlled direct shear instrument and insert the fixed pin into the corresponding pin hole 7 to assemble the shear box, and then install the shear box on the inner wall and The bottom surface is coated with an asphalt release agent; the upper box 4 is provided with a round hole formed by a large-diameter round hole and a small-diameter round hole through which the longitudinal section is an inverted convex shape; the lower box 2 is provided with a round hole with a large diameter Holes and small-diameter round holes and blind holes with a convex longitudinal section; the inner diameters of the large round holes in the upper box 4 and the lower box 2 are both 40mm, and the height of the large round holes in the upper box 4 is 15mm. The height from the middle bottom surface to the scale mark is 10mm, the height of the large...

Embodiment 3

[0049] The method of the present embodiment comprises the following steps:

[0050] Step 1. Align the upper box 4 and the lower box 2 in the improved strain-controlled direct shear instrument and insert the fixed pin into the corresponding pin hole 7 to assemble the shear box, and then install the shear box on the inner wall and The bottom surface is coated with an asphalt release agent; the upper box 4 is provided with a round hole formed by a large-diameter round hole and a small-diameter round hole through which the longitudinal section is an inverted convex shape; the lower box 2 is provided with a round hole with a large diameter Holes and small-diameter round holes and blind holes with a convex longitudinal section; the inner diameters of the large round holes in the upper box 4 and the lower box 2 are both 40mm, and the height of the large round holes in the upper box 4 is 15mm. The height from the middle bottom surface to the scale mark is 10mm, the height of the large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com