Rockfill material blasting grade prediction method for water-power engineering

A technology of hydropower engineering and prediction method, which is applied in the field of rockfill blasting, can solve the problems of not being able to rely on experience, poor optimizability, and insufficient scope of application, etc., and achieve the effect of convenient engineering site application, simple equipment and processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

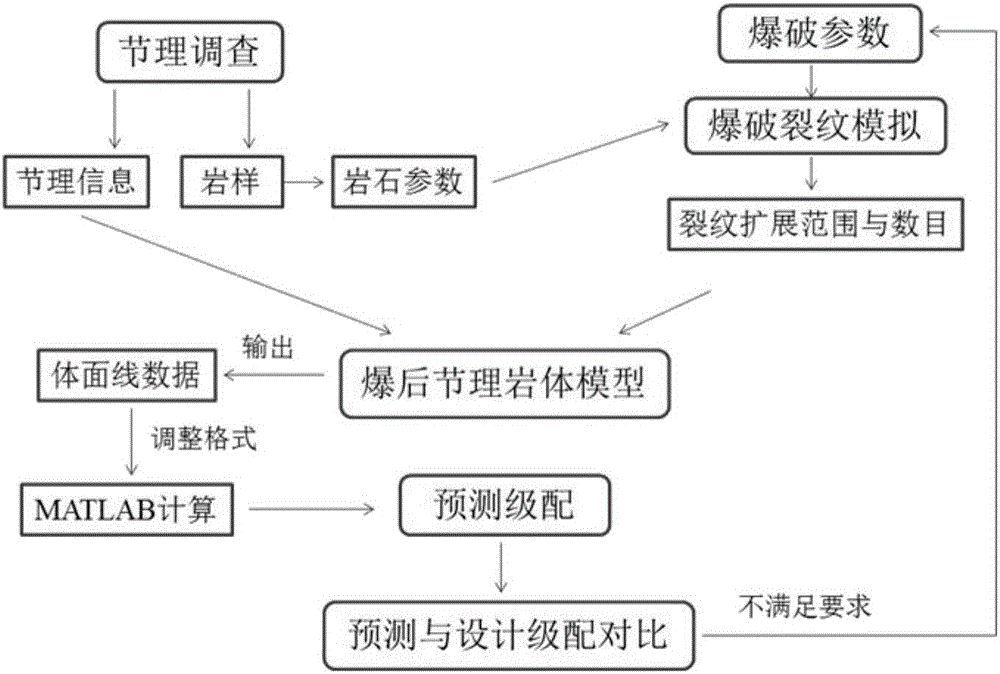

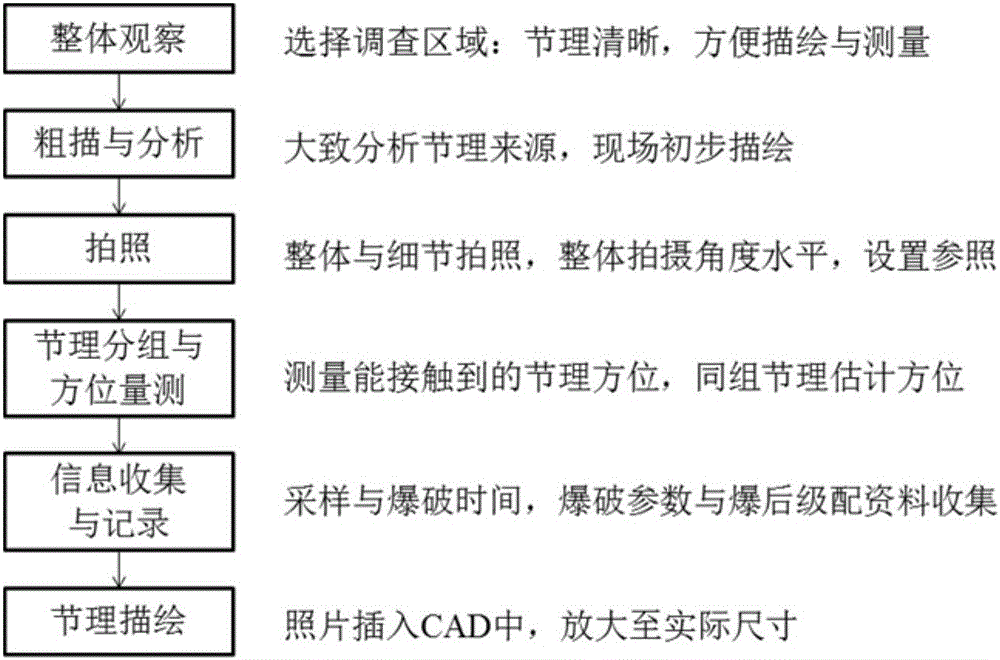

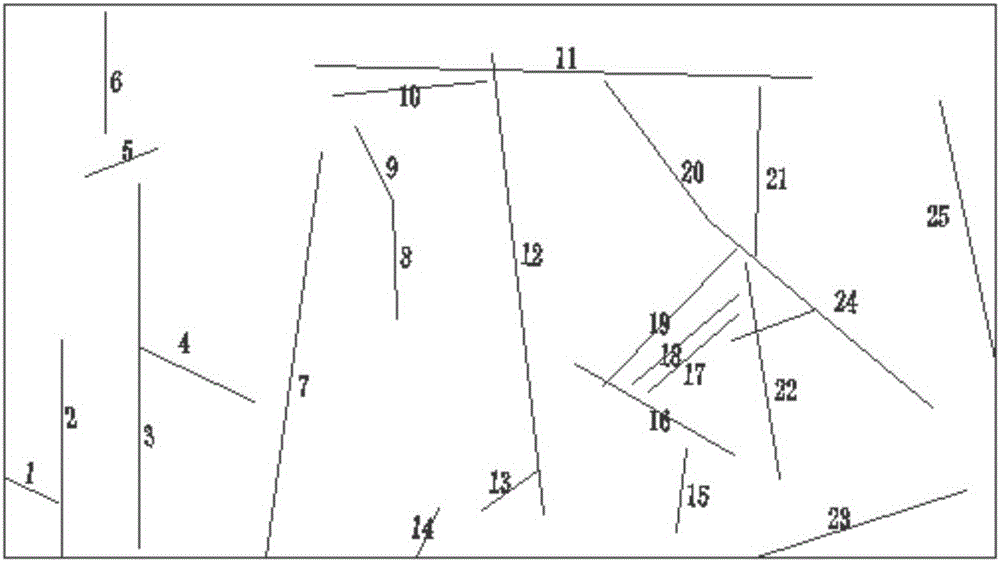

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The method for predicting blasting gradation of rockfill materials used in hydropower projects provided by the invention can realize the prediction of blasting gradation curves of jointed rock mass both in the case of excavated and unexcavated mountain bodies. The factors involved mainly include materials and blasting. The impact of blasting considers the blasting mechanism and blasting construction parameters. The impact of materials considers the joint survey scale, joint position and orientation elements, rock mass and explosive parameters. The survey scale of joints and simulation results of burst cracks have the greatest influence on the prediction accuracy. The following is a blasting gradation prediction for a typical jointed rock mass in Changhe Bajiangzui stockyard.

[0030] Concrete technical scheme of the present invention m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com