Method for composite geo-membrane sloping core cofferdam

A technology of composite geomembrane and cofferdam, which is applied in basic structure engineering, construction, etc., can solve the problems of difficult construction of cofferdam and its anti-seepage system, long linear construction period, etc., so as to shorten the linear construction period and speed up the project construction progress. , The effect of simplifying the partition of the weir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

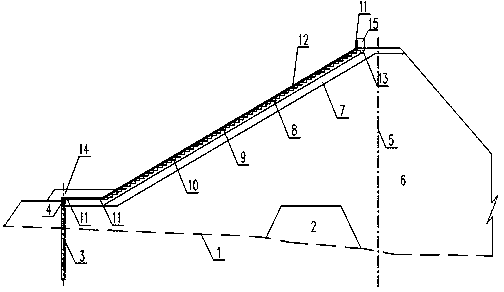

[0011] like figure 1 As shown, after the filling of the closure dike 2 is completed, the construction platform is firstly filled upstream, the lower anti-seepage structure 3 is constructed upstream, and the top of the lower anti-seepage structure is anchored with concrete 4. At the same time, the cofferdam is filled simultaneously downstream Construction, the cofferdam weir body of each filling layer is filled with concrete extrusion side wall 9, weir body cushion material 8, weir body transition material 7, and weir body rockfill material 6 from upstream to downstream. Build to the top, set the anchor concrete 13 on the top of the weir, and then lay the composite geomembrane 10 on the water-facing surface. The top of the composite geomembrane is anchored with the weir top anchorage concrete by mechanical anchoring; the bottom of the composite geomembrane is anchored by mechanical anchorage and the lower anti-seepage structure. Concrete anchorage, weir bottom anchorage concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com