Deep sea wind power generation jacket type single pile composite structure and construction method thereof

A composite structure and jacket technology, applied in infrastructure engineering, construction, etc., can solve the problems of long piles, thick walls, large pile diameters, etc., to reduce the cost of sea use, reduce the projected area, and reduce the amount of steel used. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

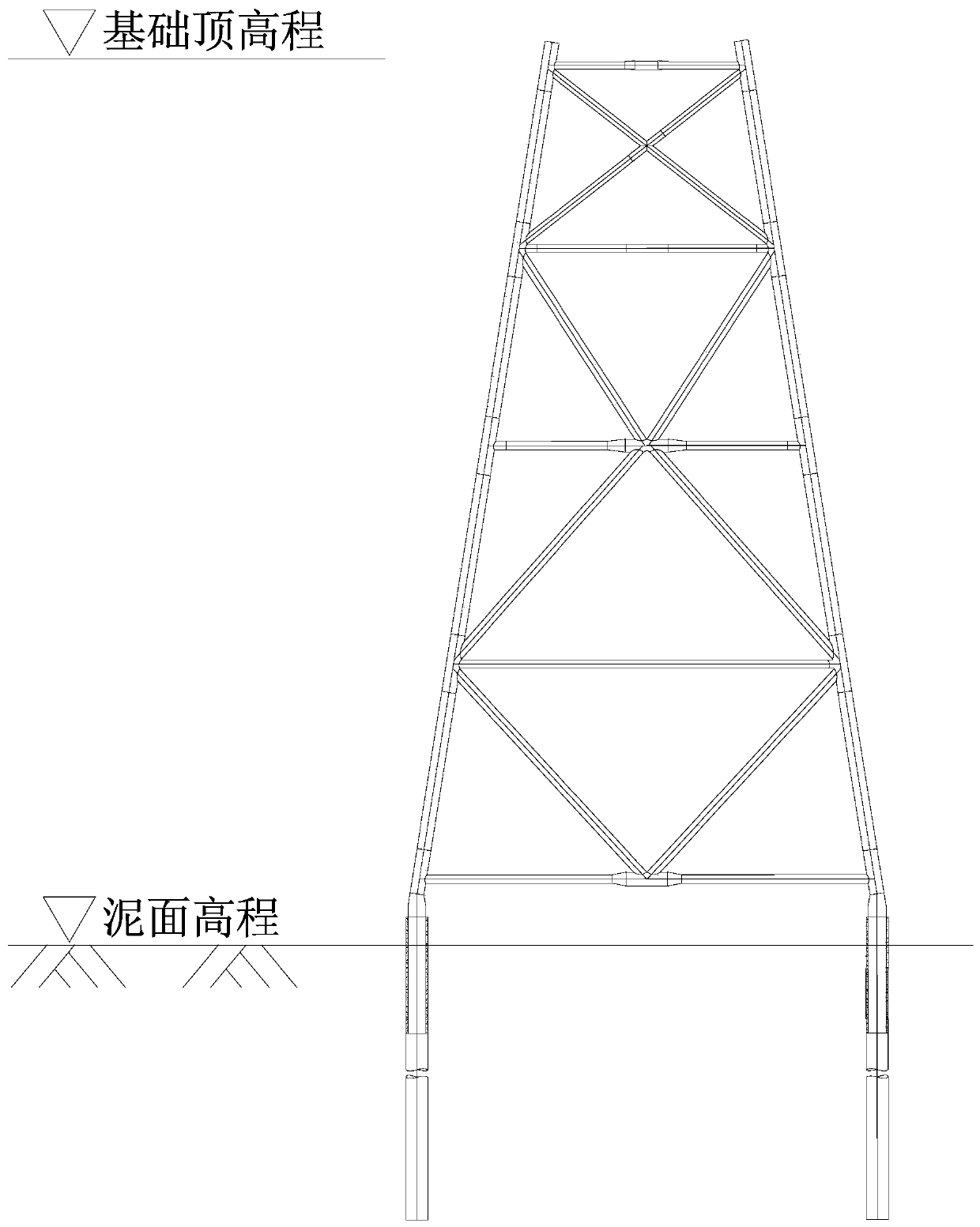

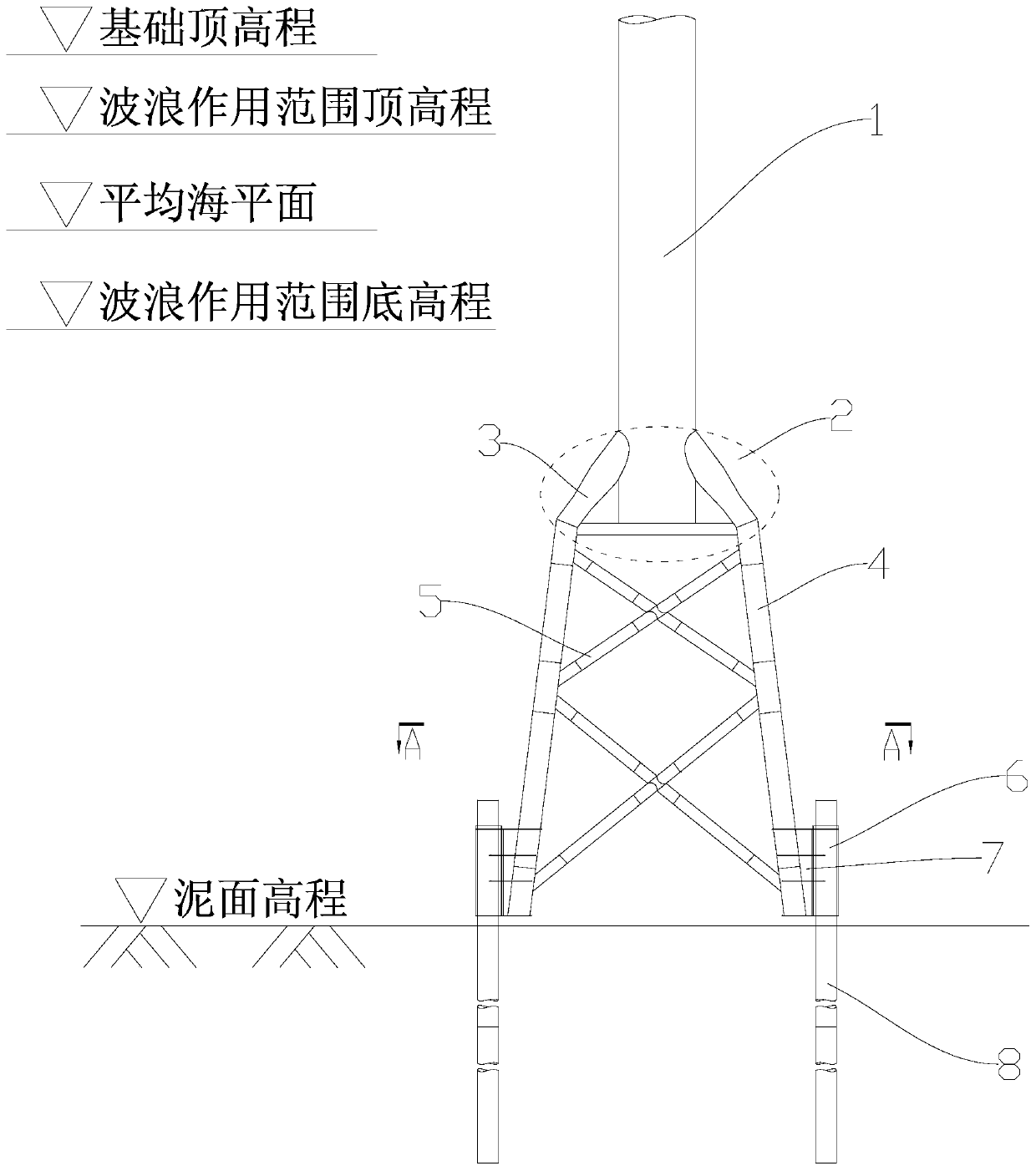

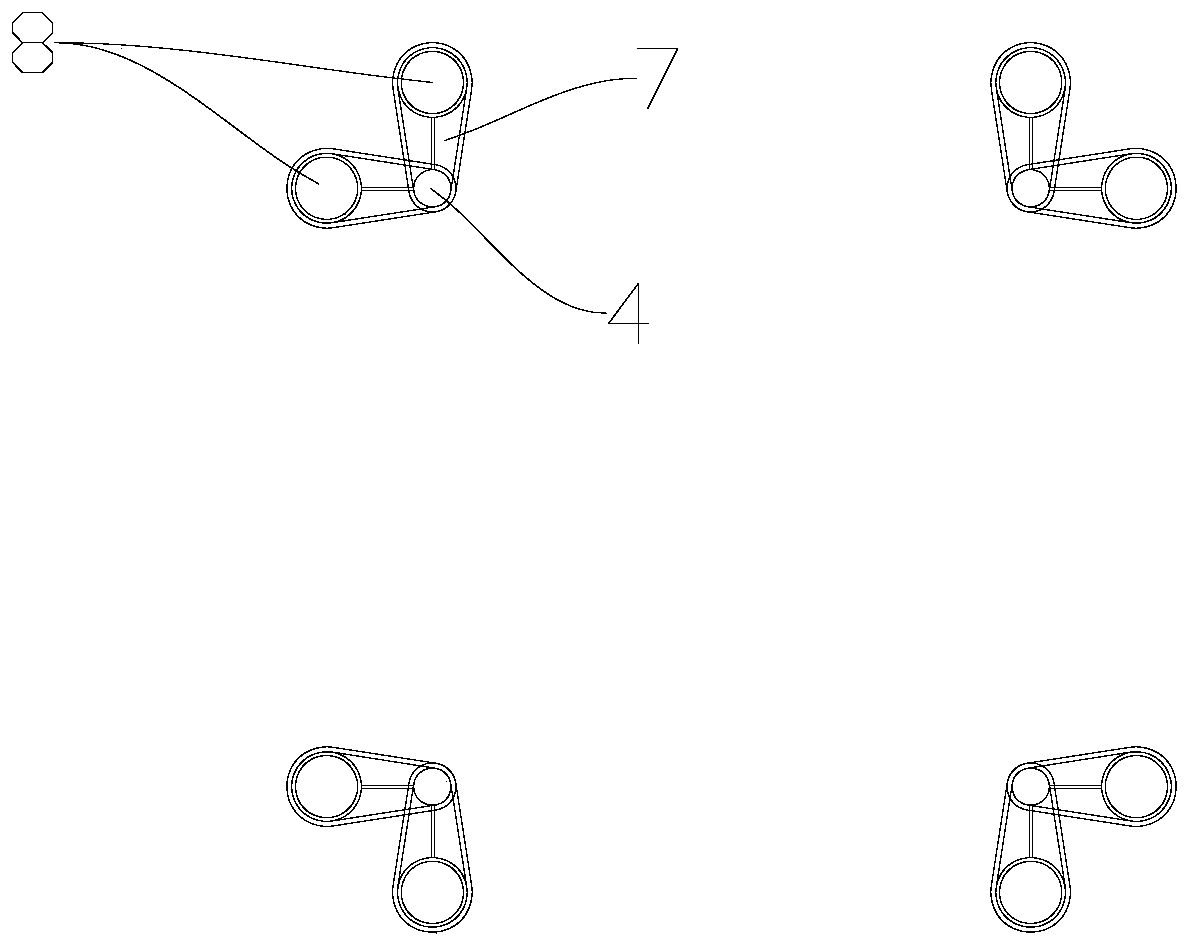

[0031] This embodiment is a jacket-type single-pile composite structure for deep sea wind power generation, which has a large-diameter steel pipe, a transition section, a jacket main structure and steel pipe piles, and the large-diameter steel pipe is connected to the seabed through the transition section and the jacket main structure. Steel pipe piles below the surface.

[0032] In this example, the size of the large-diameter steel pipe is 5.5m to 7m, and the optimized size can be designed according to the flange diameter of the bottom section of the tower set by the wind turbine manufacturer. The length of the large-diameter steel pipe is greater than the difference between the bottom elevation of the wave action range of the single-pile composite structure service project site and the foundation top elevation, the large-diameter steel pipe is arranged vertically, and its upper end is located in the single-pile composite structure service project site Above the top elevation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com