Framework thin wall type concrete chimney outer wall and building method thereof

A concrete and thin-walled technology, applied in the field of frame thin-walled concrete chimneys, can solve the problems of unsatisfactory mechanical properties of joints, difficult construction, time-consuming and labor-intensive template support and movement, and reduce the risk of manual aerial work. , The effect of reducing the difficulty of on-site management and controllable construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

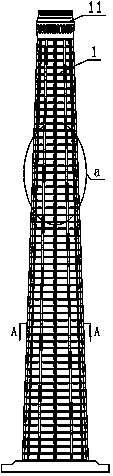

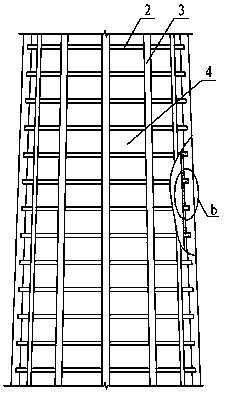

[0060] A frame thin-walled concrete chimney outer wall, which consists of: a chimney body 1, the upper part of the chimney body is connected to a top hoop 11, the chimney body includes a frame structure, and the frame structure includes a cast-in-place horizontal concrete beam 2 and the concrete columns 3 on the basis of the cast-in-place concrete beams 2, thin-walled curved prefabricated panels 4 are installed between the concrete columns 3, and the lower ends of the thin-walled curved prefabricated panels 4 are located On the horizontal concrete beam 2, the horizontal direction of the thin-walled curved prefabricated slab 4 is connected to the concrete column 3, or the thin-walled curved prefabricated slab 4 is horizontally connected to the The above-mentioned concrete column 3 is connected, and the upper end of the described thin-walled arc-shaped prefabricated plate 4 supports the above-mentioned concrete beam 2, and the described components support each other during the co...

Embodiment 2

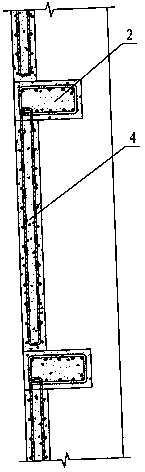

[0062] For the outer wall of the frame thin-walled concrete chimney described in Embodiment 1, the thin-walled arc-shaped prefabricated slab 4 is connected by welding between embedded connectors 41, welded connections between embedded connectors 41 and transition pieces 42, or bolts The fixed connection with the concrete column 3 and / or the concrete beam 2 is realized by means of connection or adhesive connection, and the embedded connectors 41 are all force transmission connectors, and the connection mode of the embedded connectors is better than that of the existing steel bar insertion. The installation speed of pouring method is increased by more than 80%.

Embodiment 3

[0064] For the outer wall of the frame thin-walled concrete chimney described in embodiment 1 or 2, the concrete column 3 has a concrete column formwork connection hole 31, and the end of the thin-walled arc-shaped prefabricated plate 4 has a concrete beam formwork connection hole 47. When pouring concrete beams 4 and concrete columns 5 during on-site construction, the concrete beam formwork 49 and concrete column formwork 32 can be directly connected to the formwork connection holes; the thin-walled arc-shaped prefabricated slab 4 is distributed with reinforcement mesh 43. The steel mesh 43 protrudes from the thin-walled arc-shaped precast panel 4 at the upper end, and the lower end of the thin-walled arc-shaped precast panel 4 has a slurry groove 44, and the thin-walled arc-shaped precast panel 4 The side of the lower end of 4 has a grouting hole 45, and there are installation joints between the left and right ends of the thin-walled arc-shaped prefabricated panel 4 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com