Extrusion-wall type geomembrane-faced rockfill dam

A geomembrane and extruded wall technology, applied in dams and other directions, can solve problems such as deformation, and achieve the effects of simplifying the dam body structure, fast filling and high reliability of the dam body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

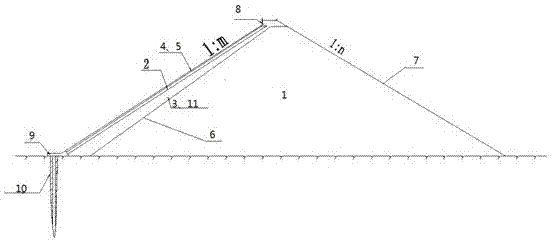

[0017] Such as figure 1 As shown, the extruded wall geomembrane face dam has a trapezoidal dam body 1 made of stone materials, and the slopes on both sides of the dam body 1 are the upstream side dam 6 and the downstream side dam 7 respectively.

[0018] The slope ratio of the upstream side dam 6 is 1:m, the slope ratio of the downstream side dam 7 is 1:n, the surface of the upstream side dam 6 is the cushion layer area 11, and the cushion layer area 11 is specifically filled with rockfill materials, including blocks Stone, gravel or a mixture of the two. The bedding area 11 is a transition area.

[0019] The selection of rockfill materials must meet the relevant requirements of the "Code for Design of Concrete Faced Rockfill Dams" (DL / T5016-2011, SL228-98).

[0020] The top of the dam body 1 is provided with a wave wall 8 , the bottom of the upstream side dam 6 is provided with a toe board 9 , and the bottom of the toe board 9 is provided with a curtain grouting 10 , and th...

Embodiment 2

[0027] Such as figure 1 As shown, among the slopes on both sides of the dam body 1, the slope ratio 1:m of the upstream side dam 6 is 1: (1.35—2.5), and the downstream side dam 7 is slightly steeper than the upstream side dam 6, and its slope ratio 1:n is 1: (1.25—2.5).

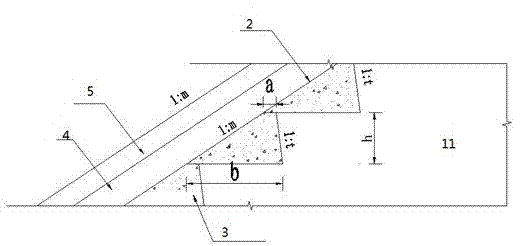

[0028] Such as figure 2 As shown, according to the situation of the upstream side dam 6 and the downstream side dam 7, the top width a of each step of the extruded wall 3 is 10 cm, the height t is 40 cm, and the height t of the extruded wall 3 and the bottom width b are constant. angle with a slope ratio of 0.125. The above parameters must meet the requirements of the "Code for Design of Concrete Face Rockfill Dams" (DL / T5016-2011, SL228-98).

[0029] Adopt the same method as in Example 1 to construct this extruded wall-type geomembrane face dam, which will not be described in detail here. Among them, for the structure of the dam body, the settlement, deformation, stress and slope stability of the dam bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com