Coarse particle contraction rule method based on fractal theory

A fractal theory and coarse-grain technology, applied in the field of coarse-grain scaling and coarse-grain scaling based on fractal theory, can solve problems such as difficulty in guaranteeing accuracy and lack of accurate and reasonable regulations for fine-grain content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

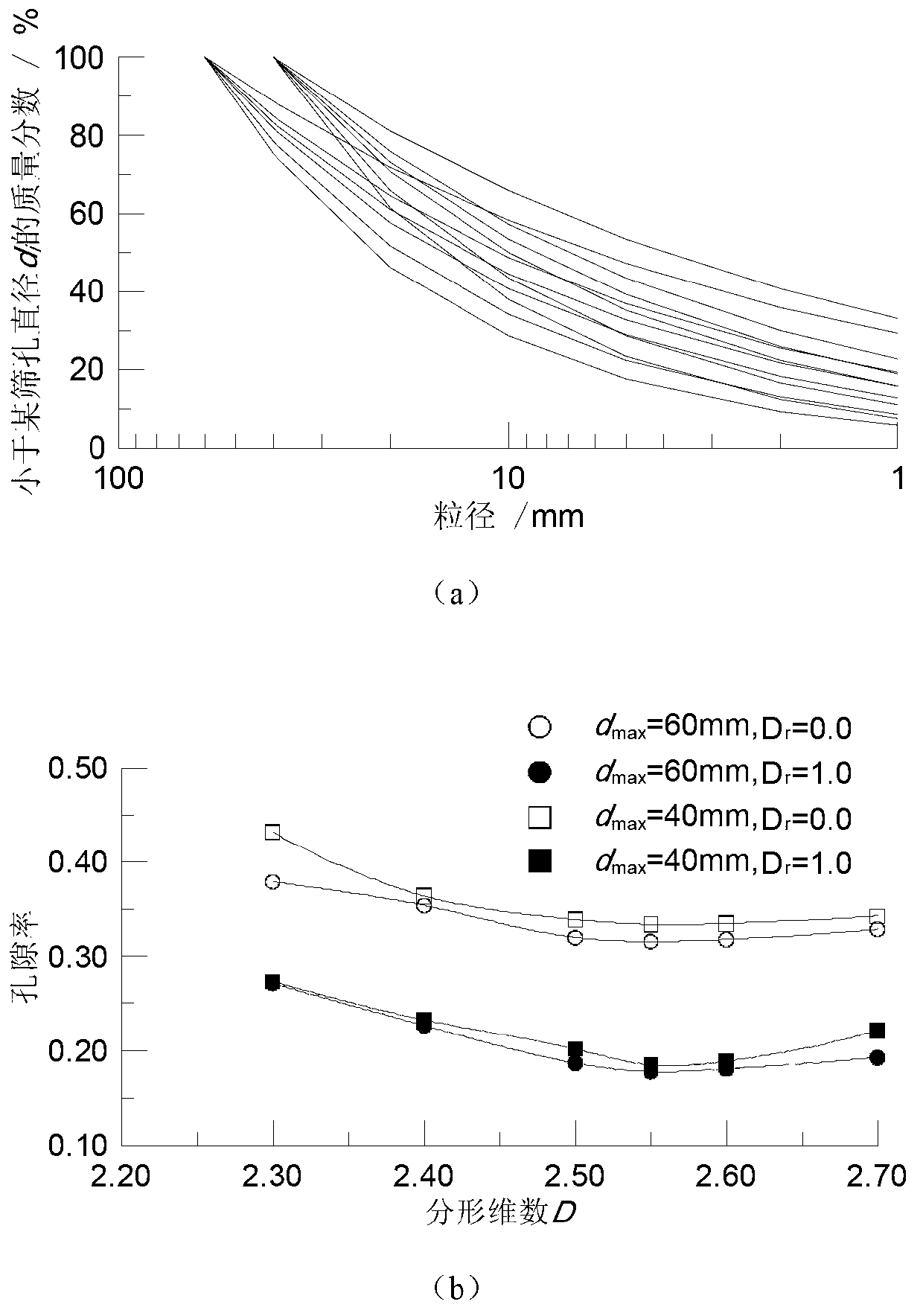

[0089] Example 1 A certain engineering original gradation coarse aggregate, gradation see image 3 (b), d 0max =800mm.

[0090] (1) Scaling method of the present invention

[0091] (1) Calculate the original gradation fractal dimension

[0092] Calculate the fractal dimension of the original gradation according to formula (1), and calculate the fractal dimension D 0 =2.40.

[0093] (2) Determine the scaling method

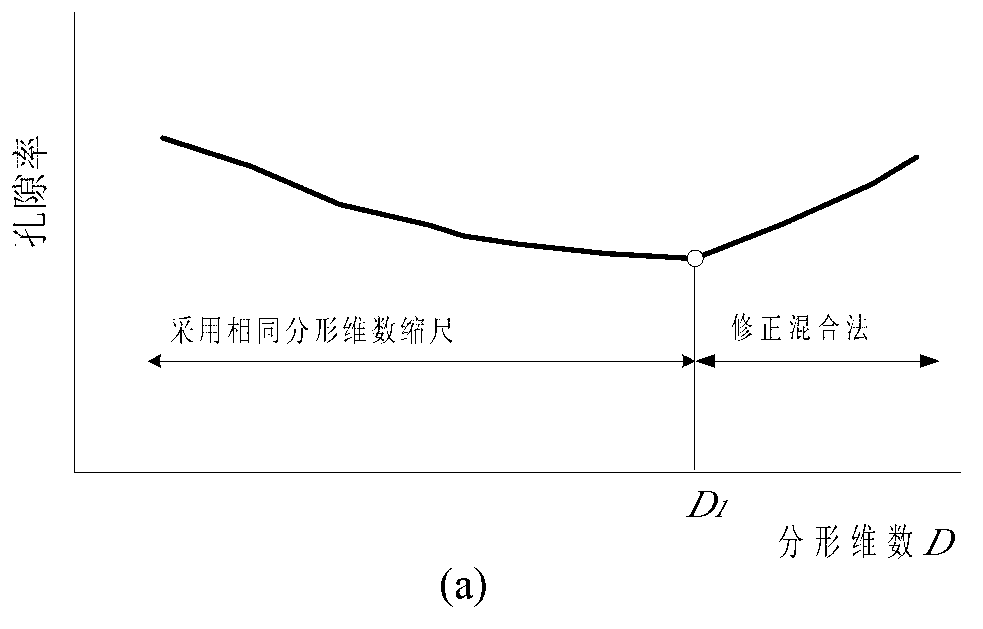

[0094] Depend on Figure 4 It can be seen that D 0 =2.40l =2.50; therefore formula (6) is used to calculate the scale gradation.

[0095] (3) Determine scale grading

[0096] In this example, the maximum particle size of scaled grading d max Take 60mm, 80mm, 100mm, 150mm, 200mm respectively, and use the same fractal dimension of 2.40 to get scaled gradation, see image 3 (b) or numbers (2)-(6) in Table 2.

[0097] Table 2 Calculation Example 1 Coarse Grain Particle Grading Table

[0098]

(1)

(2)

(3)

(4)

(5)

(6)

(7)...

Embodiment 2

[0104] Example 2 For the original gradation coarse-grained material of a certain project, see image 3 (c), d 0max =800mm.

[0105] (1) Scaling method of the present invention

[0106] (1) Calculate the fractal dimension of the original graded coarse aggregate

[0107] According to the formula (1), calculate the fractal dimension of the primary ingredient, and get D 0 =2.60.

[0108] (2) Determine the scaling method

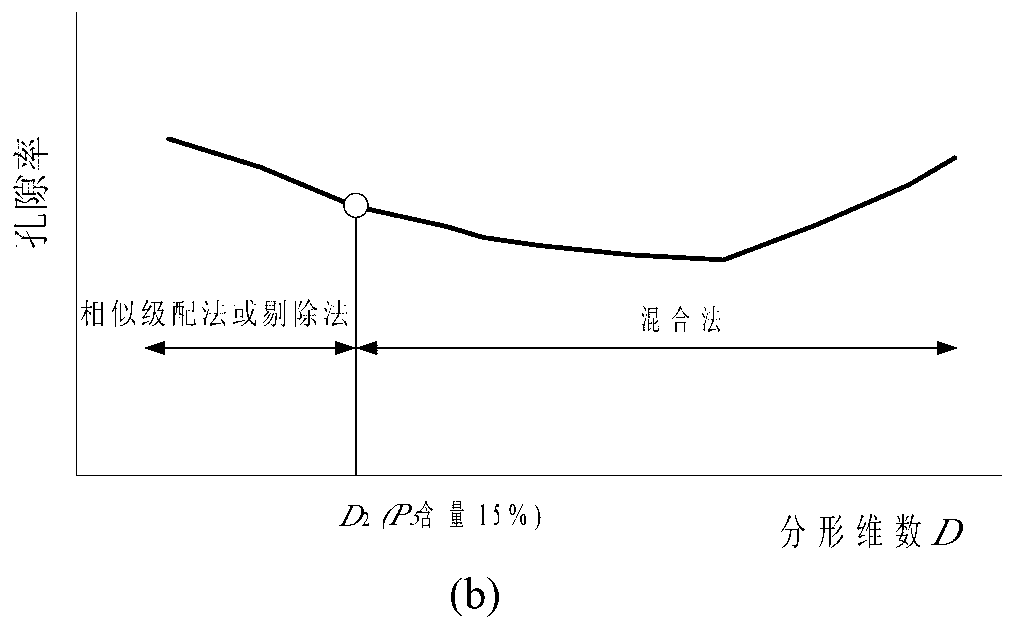

[0109] D. 0 =2.60>D l =2.50, use equations (1) and (2) to determine scale grading.

[0110] (3) Determine scale grading

[0111] when d max When they are 60mm, 80mm, 100mm, 150mm, and 200mm respectively, the maximum allowable fine particle content P after scale down 5l From formula (3), it can be obtained that they are 28.9%, 25.0%, 22.4%, 18.3%, and 15.8%, respectively. scale grading see image 3 (c) or numbers (18)-(22) in Table 3.

[0112] Table 3 Calculation Example 2 Coarse Grain Particle Grading Table

[0113]

(12)

(13)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com