Coarse particle contraction rule method based on fractal theory

A technology of fractal theory and coarse grain material, which is applied in the scaling of coarse grain material, and in the field of scaling of coarse grain material based on fractal theory, can solve the problems that there is no accurate and reasonable regulation on fine grain content, and the accuracy is difficult to guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

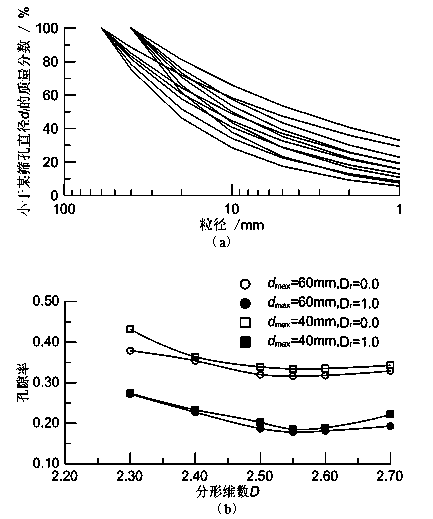

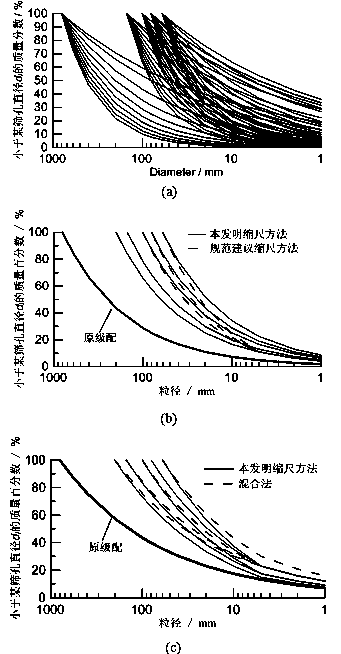

[0086] Example 1 A certain engineering original gradation coarse aggregate, gradation see image 3 (b), d 0max =800mm.

[0087] (1) scaling method of the present invention

[0088] (1) Calculate the original gradation fractal dimension

[0089] Calculate the fractal dimension of the original gradation according to formula (1), and calculate the fractal dimension D 0 =2.40.

[0090] (2) Determine the scaling method

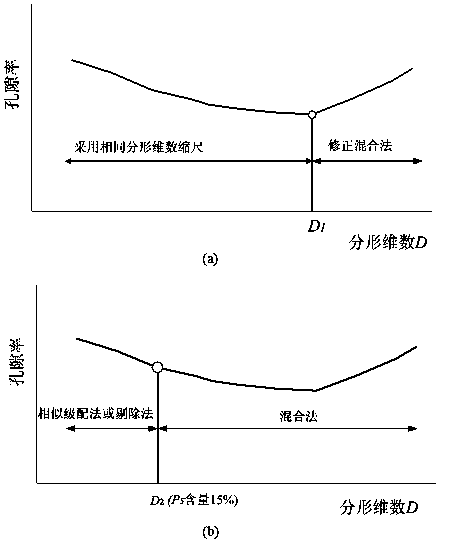

[0091] Depend on Figure 4 It can be seen that D 0 =2.40l = 2.50; therefore formula (6) is used to calculate scale gradation.

[0092] (3) Determine scale grading

[0093] In this example, the maximum particle size of scaled grading d max Take 60mm, 80mm, 100mm, 150mm, 200mm respectively, and use the same fractal dimension of 2.40 to get scaled gradation, see image 3 (b) or numbers (2)-(6) in Table 2.

[0094] Table 2 Calculation Example 1 Coarse Grain Particle Grading Table

[0095]

(1)

(2)

(3)

(4)

(5)

(6)

(7)

...

Embodiment 2

[0101] Example 2 For the original gradation coarse-grained material of a certain project, see image 3 (c), d 0max =800mm.

[0102] (1) scaling method of the present invention

[0103] (1) Calculate the fractal dimension of the original graded coarse aggregate

[0104] Calculate the fractal dimension of the primary ingredients according to formula (1), get D 0 =2.60.

[0105] (2) Determine the scaling method

[0106] D. 0 =2.60>D l =2.50, use formula (1) and (2) to determine scale gradation.

[0107] (3) Determine scale grading

[0108] when d max When they are 60mm, 80mm, 100mm, 150mm, and 200mm respectively, the maximum allowable fine particle content P after scale down 5l It can be obtained from formula (3), respectively 28.9%, 25.0%, 22.4%, 18.3%, 15.8%. scale grading see image 3 (c) or numbers (18)-(22) in Table 3.

[0109] Table 3 Calculation Example 2 Coarse Grain Particle Grading Table

[0110]

(12)

(13)

(14)

(15)

(16)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com