Single-component acrylate waterproof coating

A technology of acrylate and waterproof coatings, applied in coatings and other directions, can solve the problems of low comprehensive performance of waterproof coatings, and achieve the effects of excellent outdoor aging resistance, good weather resistance, and low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

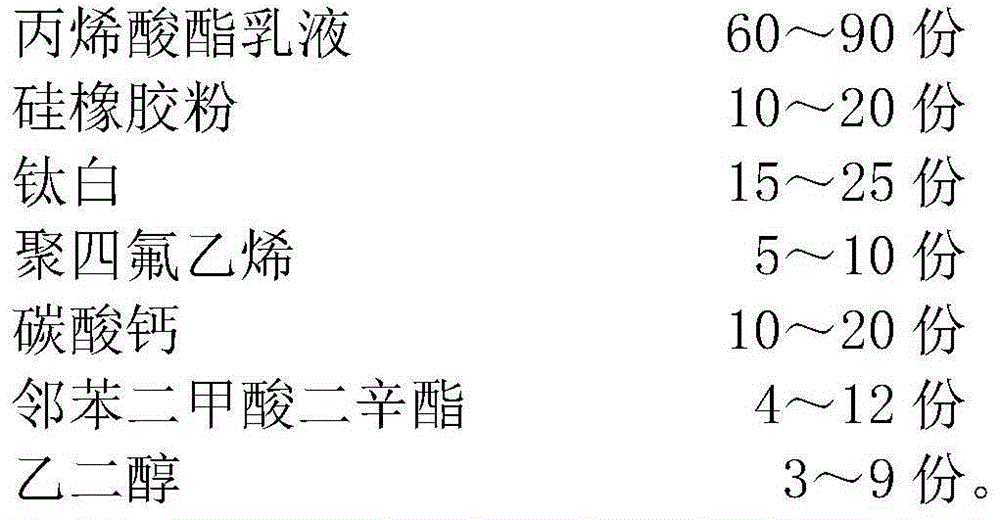

[0020] 1) Take raw materials by weighing the following parts by weight:

[0021]

[0022] 2) Mix ethylene glycol, dioctyl phthalate, and silicone rubber powder evenly, stir for 20 minutes, add titanium dioxide, polytetrafluoroethylene and calcium carbonate, and disperse at high speed for 20 minutes;

[0023] 3) Slowly pour the acrylate emulsion into the mixture, and stir at a low speed for 20 minutes to obtain the product.

Embodiment 2

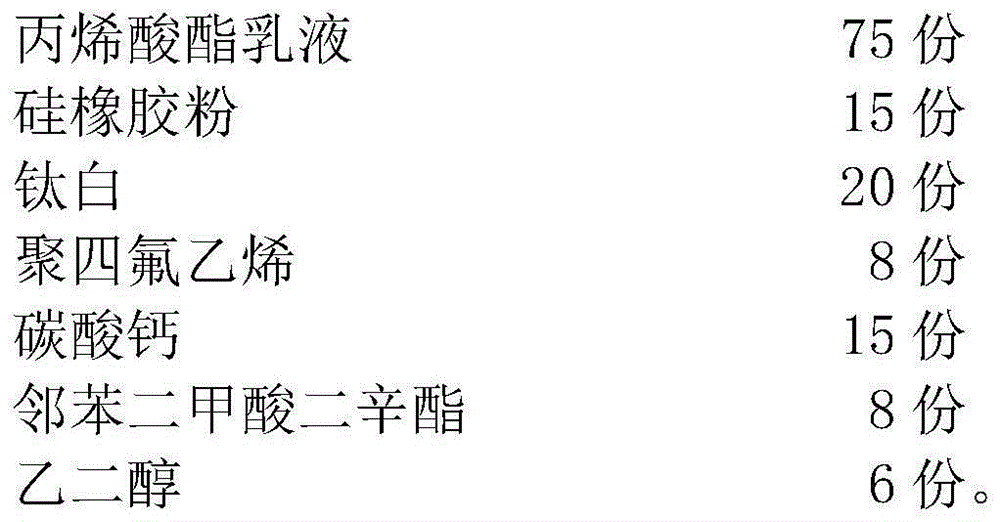

[0025] 1) Take raw materials by weighing the following parts by weight:

[0026]

[0027] 2) Mix ethylene glycol, dioctyl phthalate, and silicone rubber powder evenly, stir for 20 minutes, add titanium dioxide, polytetrafluoroethylene and calcium carbonate, and disperse at high speed for 30 minutes;

[0028] 3) Slowly pour the acrylate emulsion into the mixture, and stir at a low speed for 30 minutes to obtain the product.

Embodiment 3

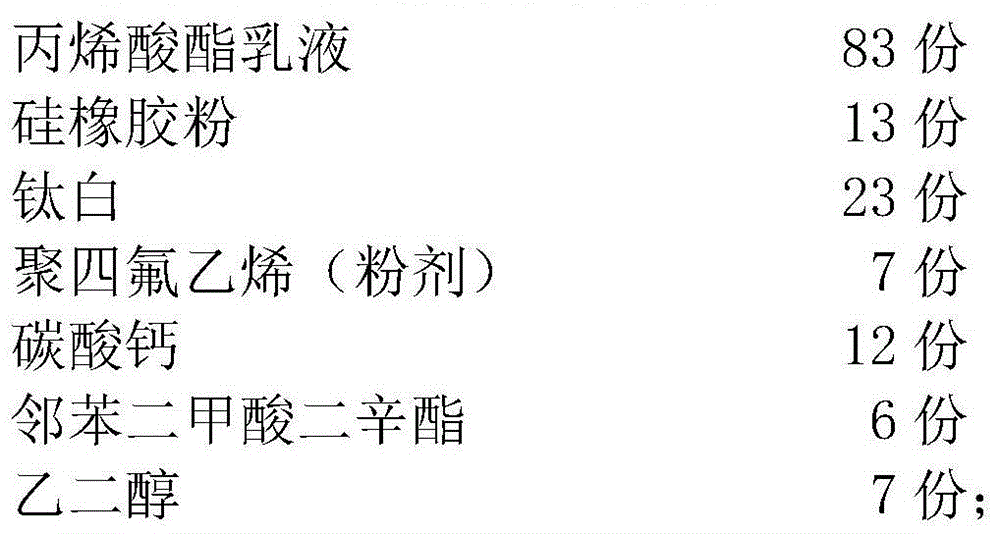

[0030] 1) Take raw materials by weighing the following parts by weight:

[0031]

[0032] 2) Mix ethylene glycol, dioctyl phthalate, and silicone rubber powder evenly, stir for 25 minutes, add titanium dioxide, polytetrafluoroethylene and calcium carbonate, and disperse at high speed for 25 minutes;

[0033] 3) Slowly pour in the acrylate emulsion, stir at a low speed for 25 minutes, and obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com