Basement connection portion crack preventing structure

A cracked structure and basement technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as ineffectiveness, appearing in settlement joints, and difficult settlement joints, so as to strengthen adhesion, reduce Cracks, the effect of removing applied stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

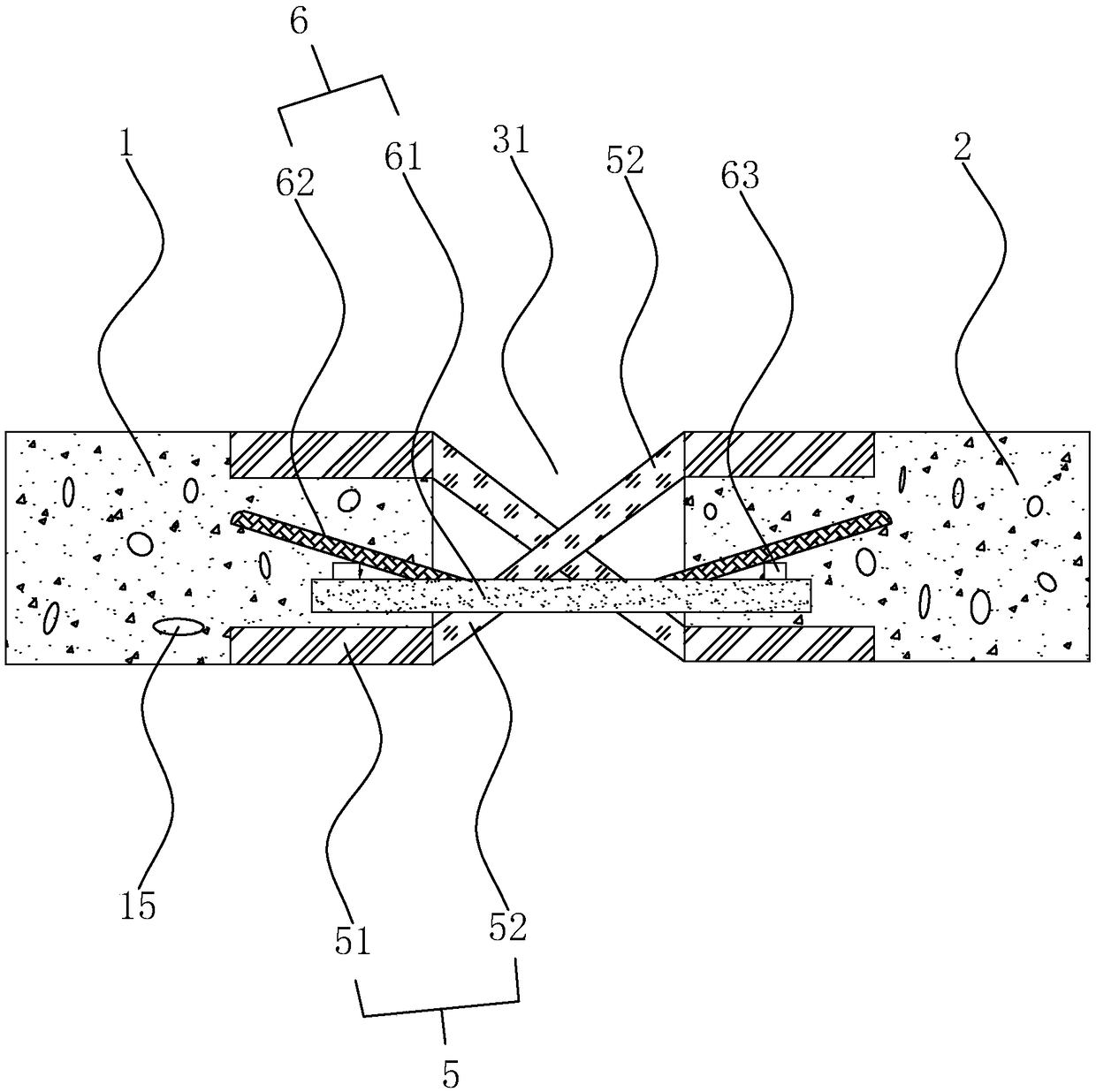

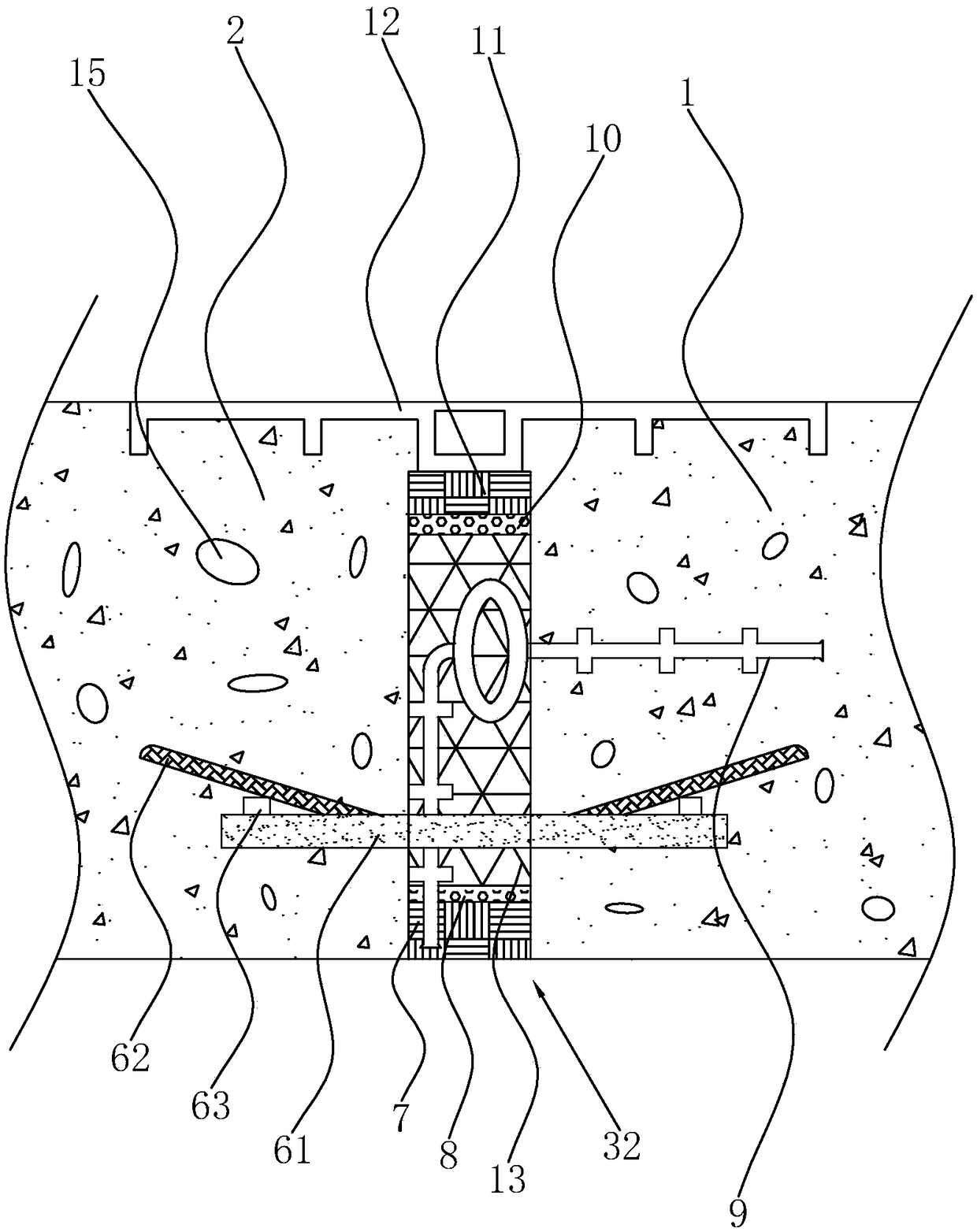

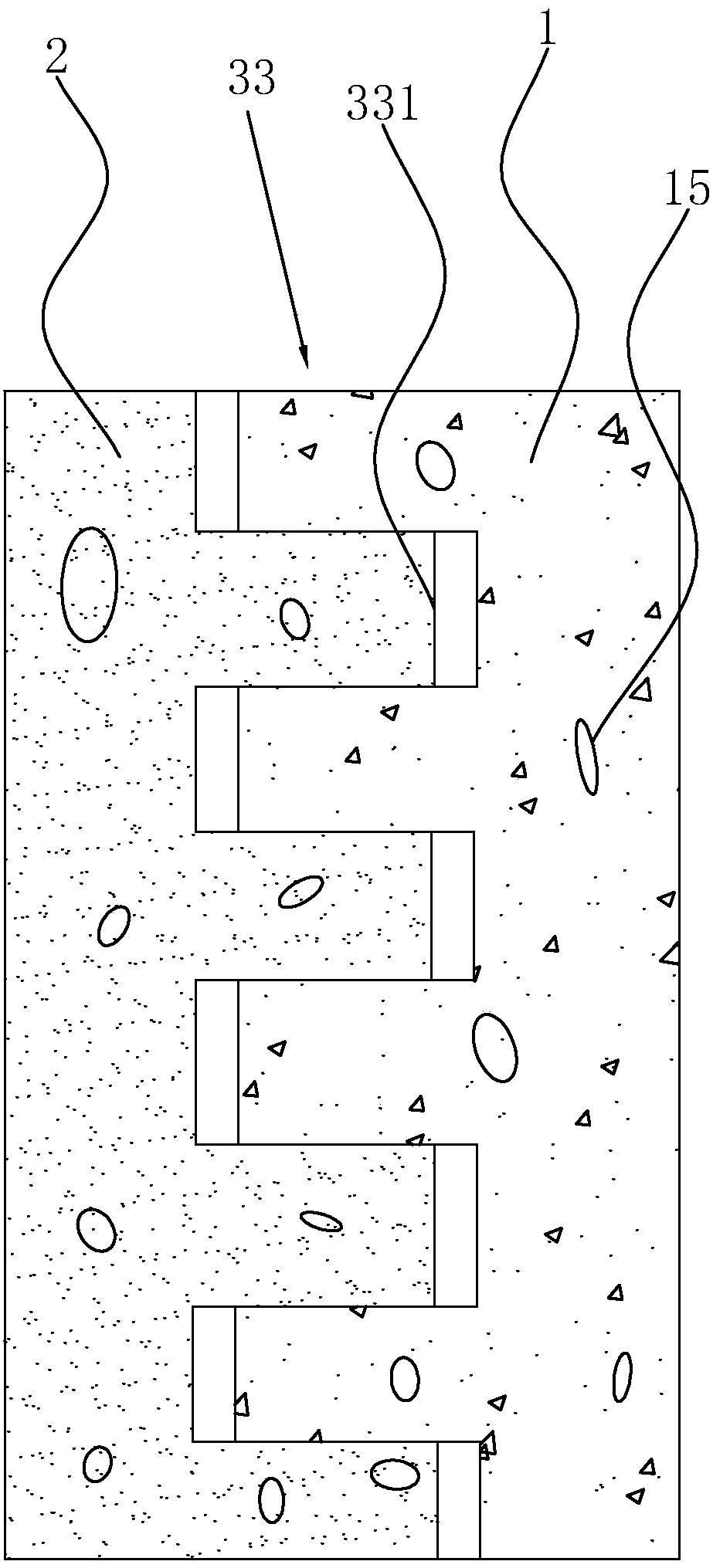

[0037] Embodiment: A basement connecting part anti-crack structure, including an inner connecting part 1 and an outer connecting part 2, the inner connecting part 1 is integrally connected with the basement, the outer connecting part 2 is directly connected to other buildings outside the basement, and the inner connecting part A deformation buffer seam is left between 1 and the outer connecting part 2. refer to Figure 1-3 , the deformation buffer seam is provided for one week, including a bottom horizontal seam 31, a top horizontal seam 32 and two side vertical seams 33.

[0038] Such as figure 1 As shown, the bottom horizontal seam 31 is provided with a subsidence buffer zone, and the subsidence buffer zone is provided with multiple groups of reinforcement belts 5 according to its width, and each two reinforcement belts 5 arranged in a staggered manner form a group, and the reinforcement belts 5 are formed by two The connecting section 1 and the outer connecting section 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com