Construction technique of waterproof heat-insulation integrated system

A construction technology and coating technology, applied in covering/lining, building, building structure, etc., can solve problems such as failure, affecting the health of residents, damaging office facilities, etc., to achieve thermal insulation and waterproofing, and improve comprehensive energy-saving effects , The effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

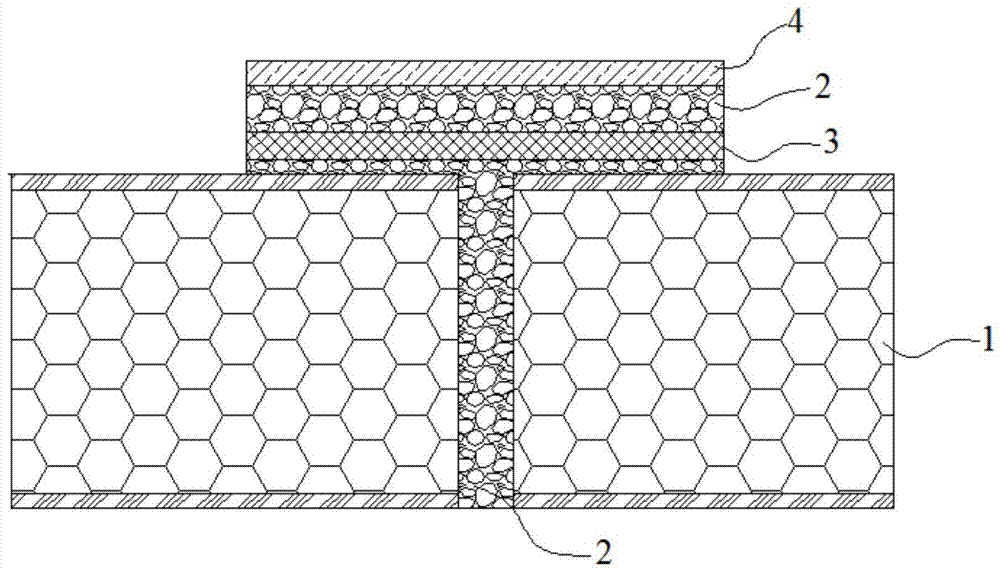

[0027] Embodiment 1: The construction process of the integrated waterproof and thermal insulation system of this embodiment includes the following steps:

[0028] Put the block rubber asphalt paint 2 into the instant adhesive machine to heat, clean the surface of the base, clean up the loose parts of the surface of the base by shot blasting or grinding, and then apply the base treatment agent on the surface of the base, and the heated Rubber asphalt paint 2 is applied to the joints that need to be strengthened, and reinforced mesh cloth is laid on the joints, and the rubber asphalt paint 2 is applied to completely cover the reinforced mesh cloth. The width is 1.2m and the length is 7.5m;

[0029] Cut the bottom surface of the board 1 horizontally and vertically from bottom to top at intervals of 10 cm to a distance of 5 mm from the upper surface of the board 1, cut the whole board 1 into several parts, and pour the heated rubber asphalt paint 2 on the base, Use a scraper to s...

Embodiment 2

[0031] Embodiment 2: The construction process of the integrated waterproof and thermal insulation system of this embodiment includes the following steps:

[0032] Put the block rubber asphalt paint 2 into the instant adhesive machine to heat, clean the surface of the base, clean up the loose parts of the surface of the base by shot blasting or grinding, and then apply the base treatment agent on the surface of the base, and the heated The rubber asphalt paint 2 is applied to the nodes, and the reinforced mesh cloth is laid on the nodes. The rubber asphalt paint 2 is applied to completely cover the reinforced mesh cloth. , with a length of 7m;

[0033] Cut the bottom surface of the board 1 horizontally and vertically from bottom to top at an interval of 30 cm to a distance of 8 mm from the upper surface of the board 1, cut the whole board 1 into several parts, and pour the heated rubber asphalt paint 2 on the base, Use a scraper to scrape rubber asphalt paint 2 on the flat sur...

Embodiment 3

[0035] Embodiment 3: The construction process of the integrated waterproof and thermal insulation system of this embodiment includes the following steps:

[0036] Put the block rubber asphalt paint 2 into the instant adhesive machine to heat, clean the surface of the base, clean up the loose parts of the surface of the base by shot blasting or grinding, and then apply the base treatment agent on the surface of the base, and the heated The rubber asphalt paint 2 is coated on the nodes, and the reinforced mesh cloth is laid on the nodes. The rubber asphalt paint 2 is applied to completely cover the reinforced mesh cloth. m, the length is 8m;

[0037] Cut the bottom surface of the plate 1 from bottom to top at intervals of 60 cm in both horizontal and vertical directions to a distance of 10 mm from the upper surface of the plate 1, cut the whole plate 1 into several parts, and pour the heated rubber asphalt paint 2 on the base, Use a scraper to scrape rubber asphalt paint 2 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com