Steel joist constrained vertical seam steel plate shear force wall

A steel plate shear wall and steel keel technology, applied to building components, building structures, earthquake resistance, etc., can solve the problems of reducing the lateral stiffness of wall panels, reducing material utilization and its economy, and increasing costs, etc., to achieve Improvement of ductility and energy dissipation performance, low cost, and effect of preventing external buckling of steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

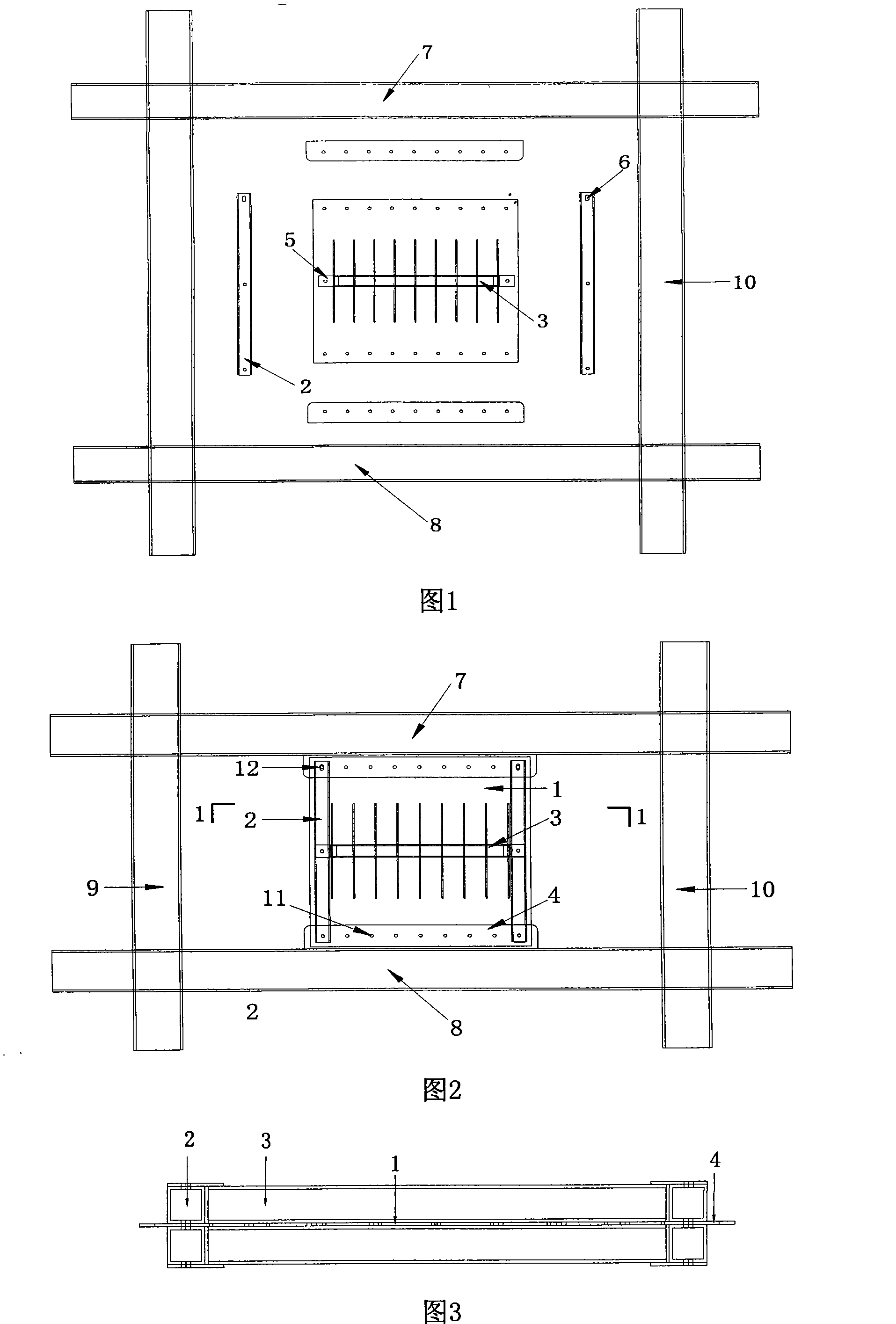

[0016] Embodiment 1: The steel keel constrained slotted steel plate shear wall of the present invention is composed of embedded vertical seam steel plate, stiffener system and edge members; the edge members are composed of upper edge frame beam 7, lower edge frame beam 8 and left edge frame Column 9 and frame column 10 on the right edge. The embedded steel plate 1 with vertical seam is made of ordinary ductile structural steel. The fishplate 4 is welded to the upper edge beam 7 and the lower edge beam 8 respectively. The high-strength friction bolts 11 are connected to the fish plate 4, and the upper end of the vertical stiffener 2 is opened with an oval hole 6 so that ordinary bolts 12 can pass through and leave enough space for sliding. The horizontal stiffener end plate 5 and the horizontal stiffener 3 It is welded and connected with the vertical stiffener 2 and the embedded vertical seam steel plate 1 through ordinary bolts 12.

[0017] The using method of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com