Fast tooth joint vertical veneer continuous splicing machine and splicing process thereof

A splicing machine and veneer technology, which is applied in veneer presses, wooden veneer joints, plywood presses, etc., can solve problems such as high cost, low tensile strength at seams, and easy occurrence of air bubbles, and achieve The effect of high fit, guaranteed strength and guaranteed tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

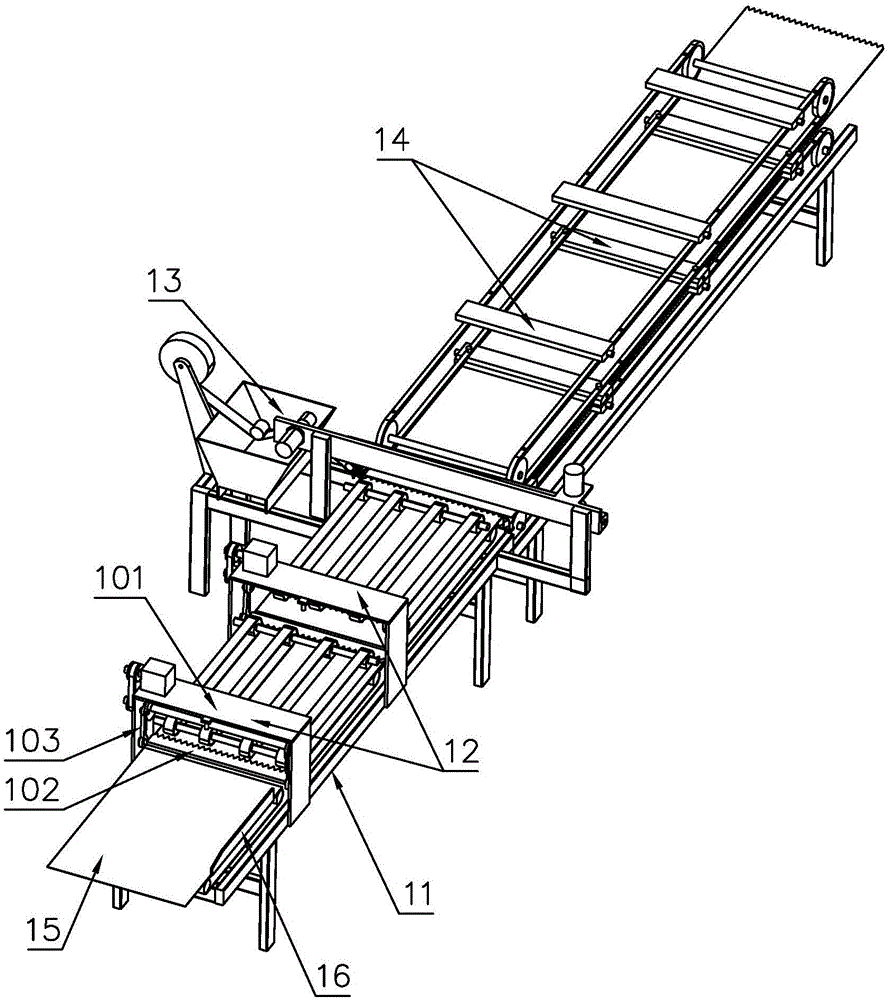

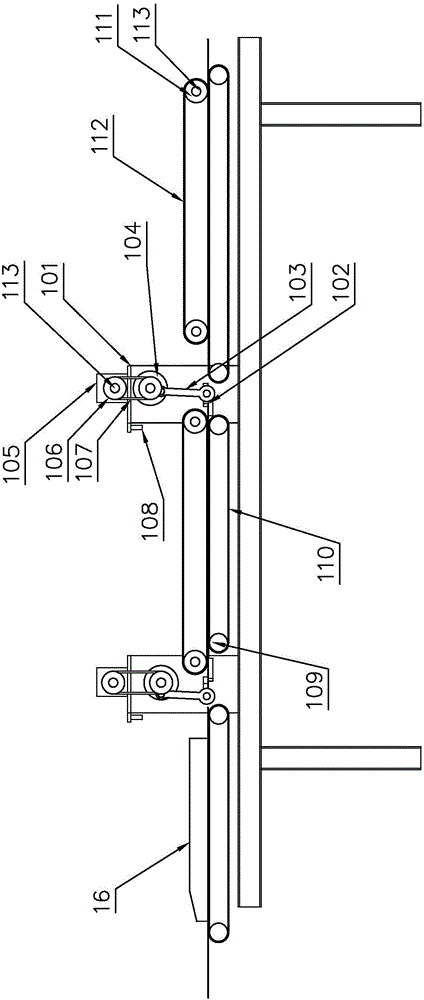

[0039] A rapid tooth-joint vertical veneer continuous splicing machine, comprising a frame 11, a comb mechanism 12, a docking mechanism 13, and a hot-press forming mechanism 14. The upper part of the frame 11 is provided with a comb mechanism 12, and the comb mechanism 12 The front end is provided with a ruler 16, and the slab 15 is guided by the ruler 16 and enters the comb mechanism 12. The side of the comb mechanism 12 is provided with a docking mechanism 13, and the side of the docking mechanism 13 is provided with a hot-press forming mechanism 14 and a frame 11. It is used to carry the comb mechanism 12, the docking mechanism 13, and the thermoforming mechanism 14.

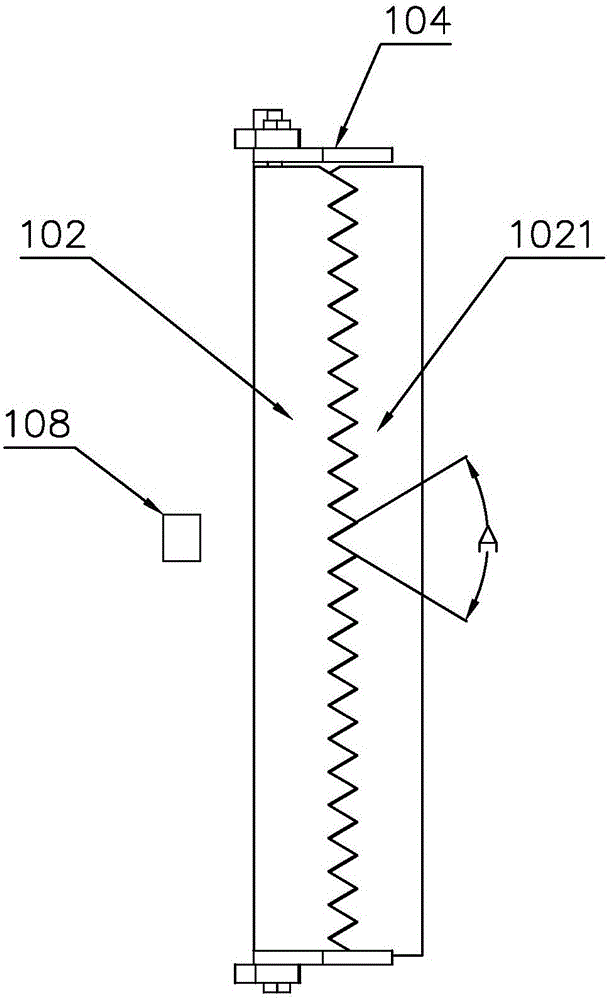

[0040] The comb tooth mechanism 12 includes a support frame 101, a comb tooth 102, an anvil block seat 1021, a connecting rod 103, an eccentric wheel 104, a motor 105, a synchronous pulley 106, a synchronous belt 107, a carrier roller 109, a carrier belt 110, and a drive roller 111, transmission belt 112, tra...

Embodiment 2

[0054] Compared with Example 1, the difference is that the comb teeth 102 are W-shaped, and the angle between the tooth surfaces of the comb teeth 102 is 90°; for the butt joint in step 3) of the splicing process, nailing is used: each The corner of one tooth is used as the splicing point. After the butt joint is completed, use the automatic plastic Martin gun group to quickly nail the butt joint to firmly splice the veneers.

Embodiment 3

[0056] Compared with Example 1, the difference is that the comb teeth 102 are W-shaped, and the angle between the tooth surfaces of the comb teeth 102 is 110°; the glue used is phenolic glue and melamine glue, and the two are mixed in any proportion. , The heating method of hot press forming is ultrasonic heating, and the heating temperature is 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com