Toothed mating surface case for compact bus groove

A busway and meshing surface technology, applied in the direction of open busbar installation, can solve the problems of easy aging and falling off of the sealant, increase the installation workload, and have many connection points, so as to ensure the sealing and waterproof effect, facilitate manufacturing and installation, and improve the The effect of the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

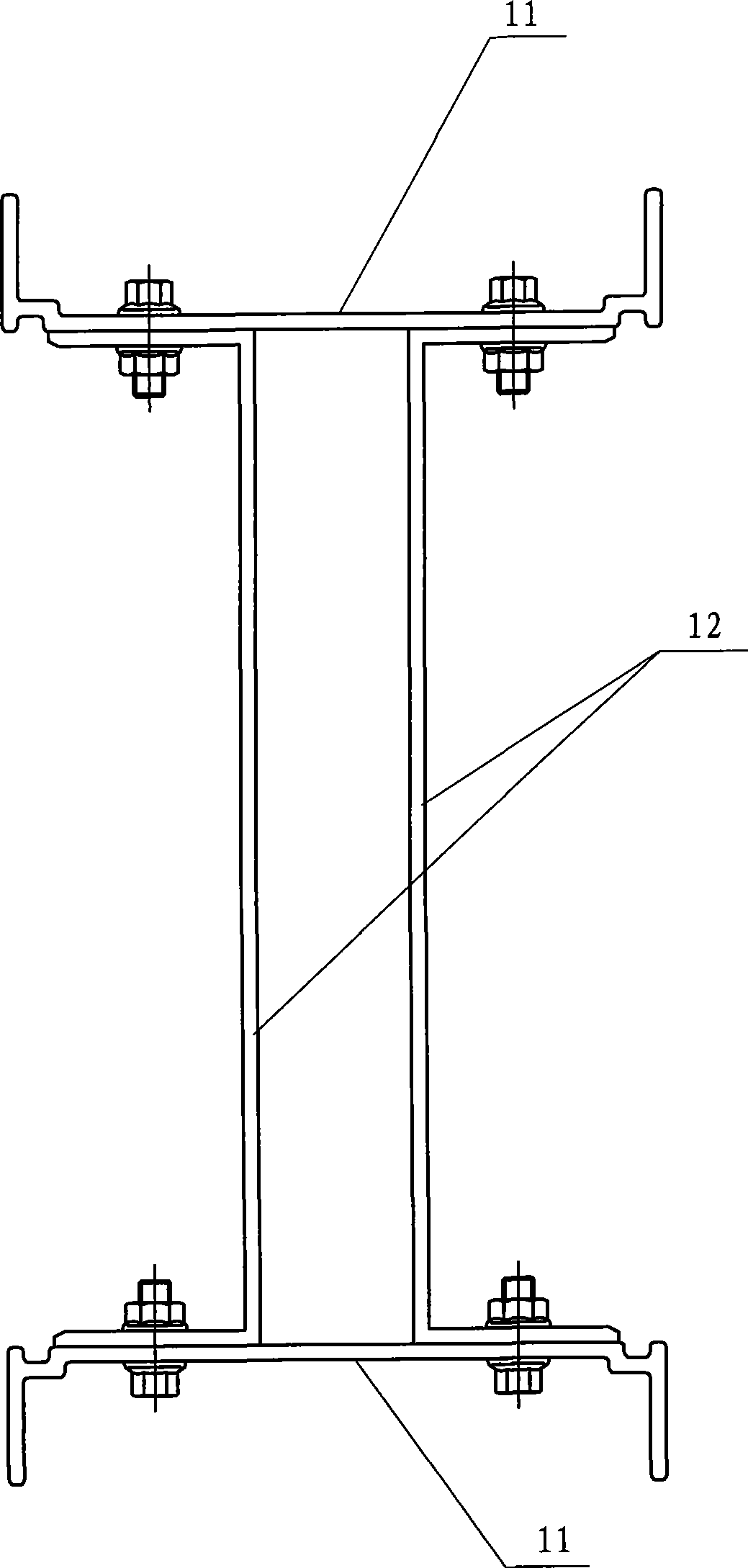

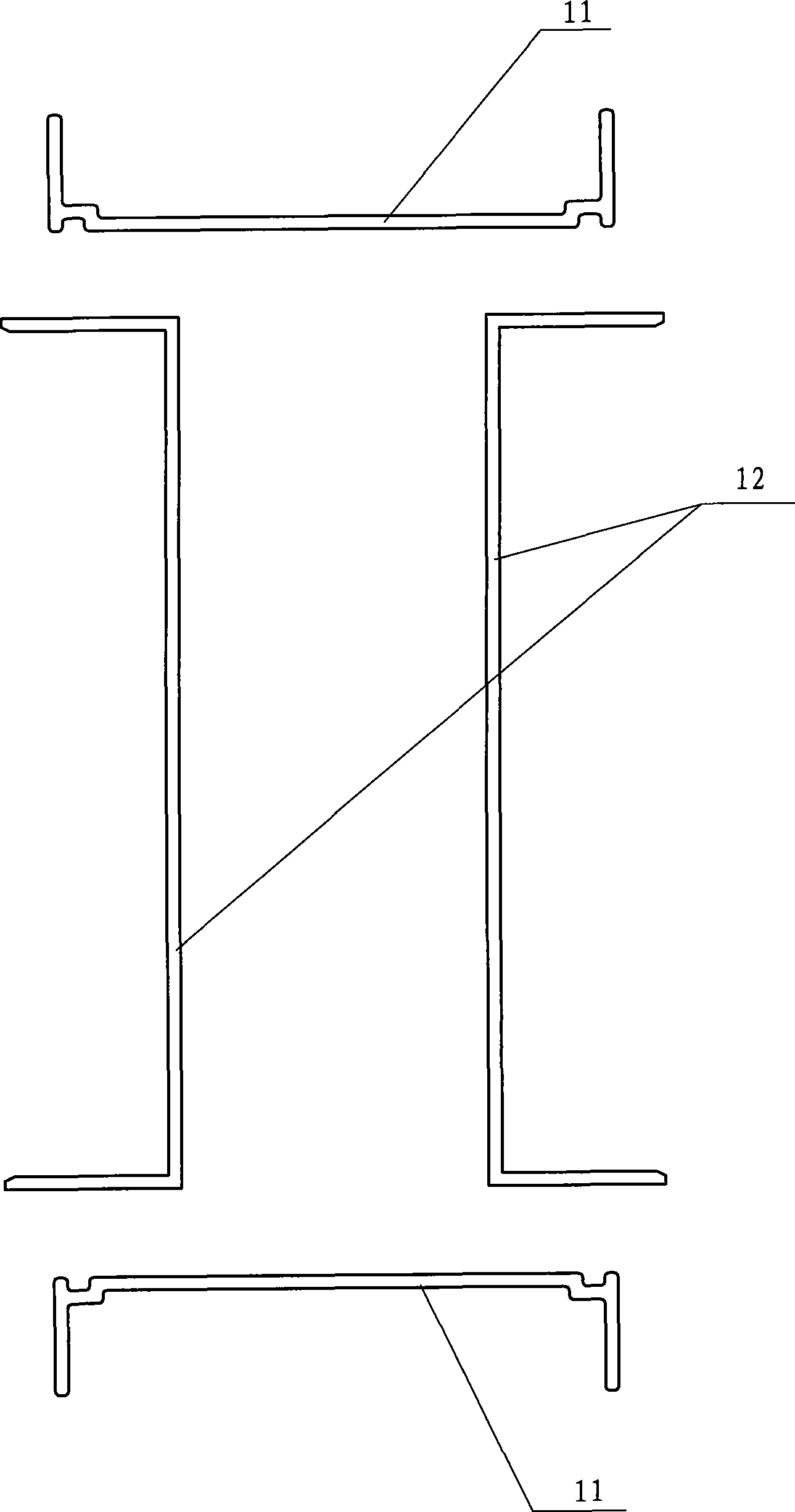

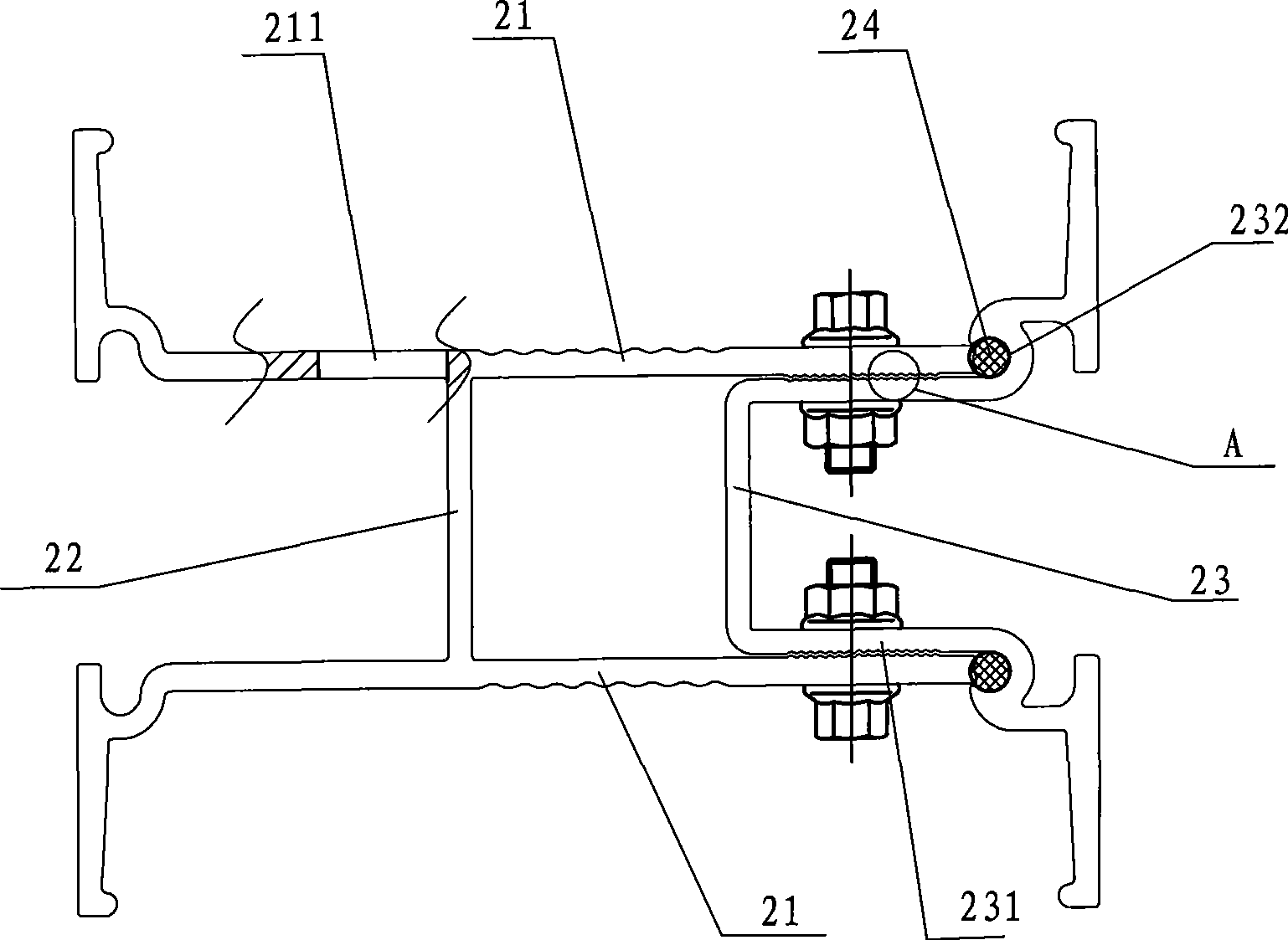

[0013] like image 3 , Figure 4 As shown, the housing of the serrated meshing surface of the intensive busway includes two upper and lower cover plates 21 and a fixed side plate 22 connected between the two cover plates and biased to one side. The two cover plates 21 are connected to the fixed side The plate 22 is made of an aluminum alloy profile with an overall structure, and a movable side plate 23 with a C-shaped cross section is arranged between the two cover plates to the other side. The cover plate is connected and fixed by bolts or rivets. The cross-sectional shape of the joint surface of the flange and the upper and lower cover plates is a sawtooth shape that engages with each other (such as Figure 5 shown). The top cover plate 21 is also provided with a drain hole 211 , and the lateral position of the drain hole is located outside the fixed side plate 22 . The edges of the two flaps 231 of the movable side plate are folded outwards to form two sealing grooves 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com