Clasp type intensive bus groove shell

A dense, busway technology, applied in the direction of open busway installation, etc., can solve the problems of increased installation workload, many connection points, heavy workload, etc., to achieve convenient manufacturing and installation, improve waterproof effect, and avoid water accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

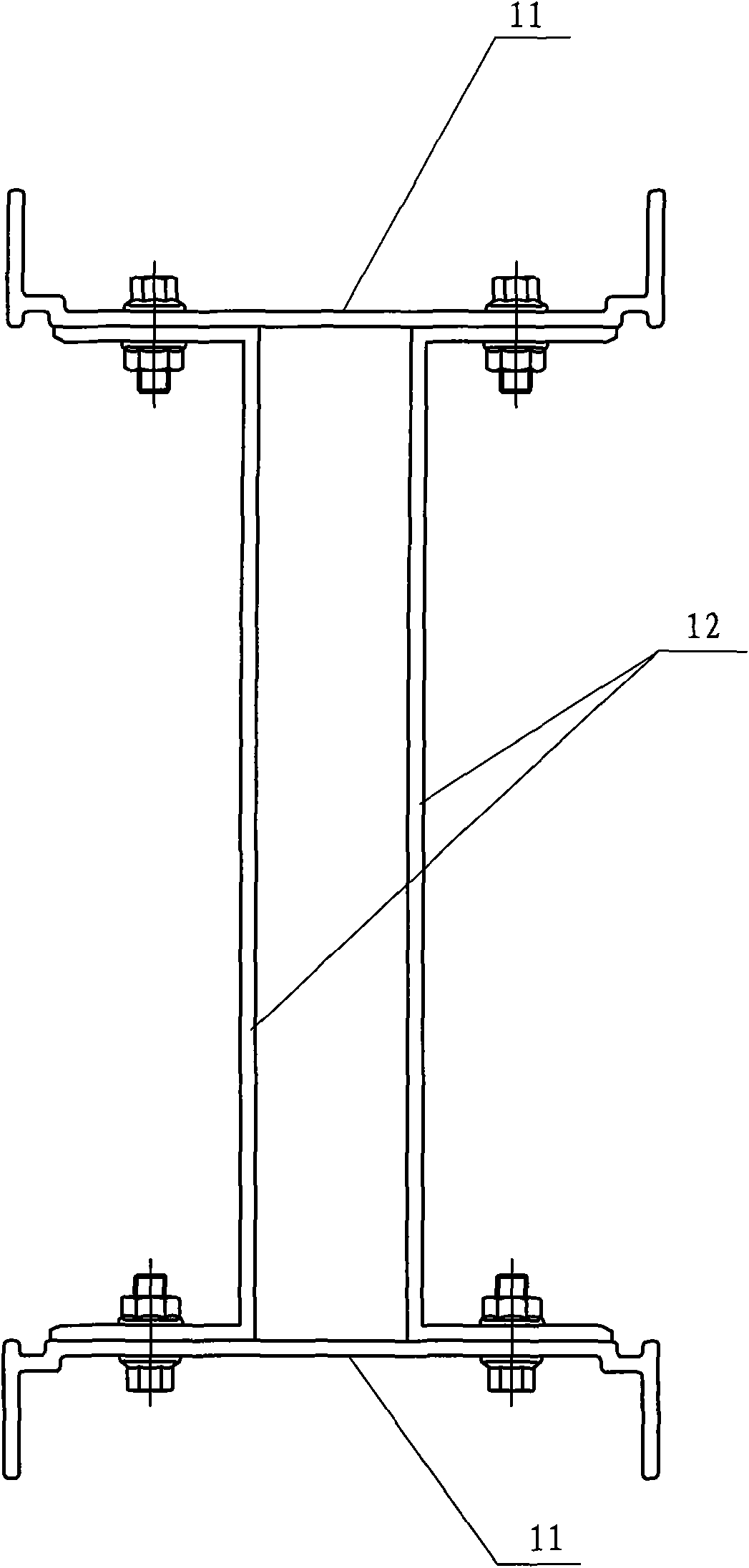

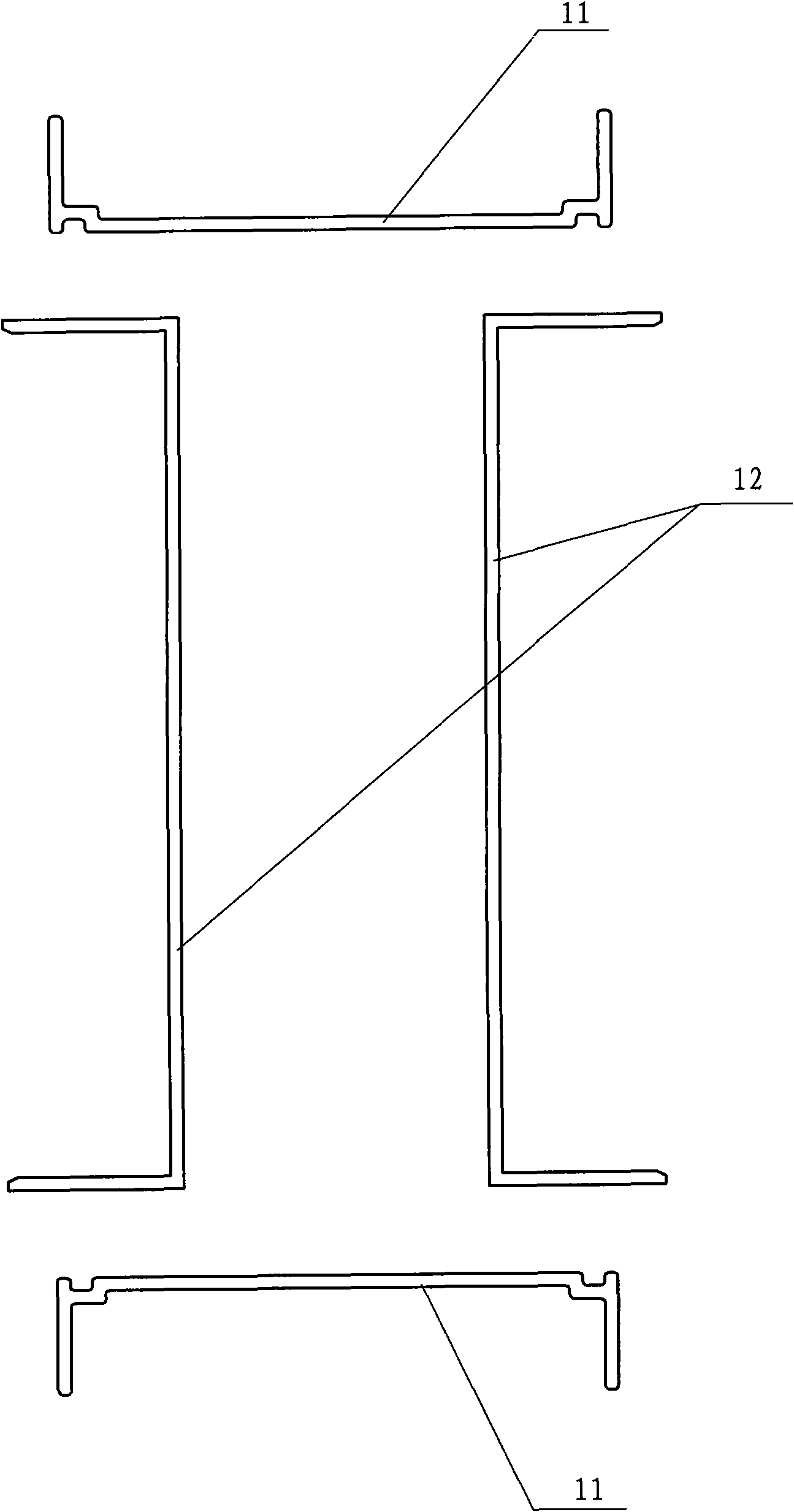

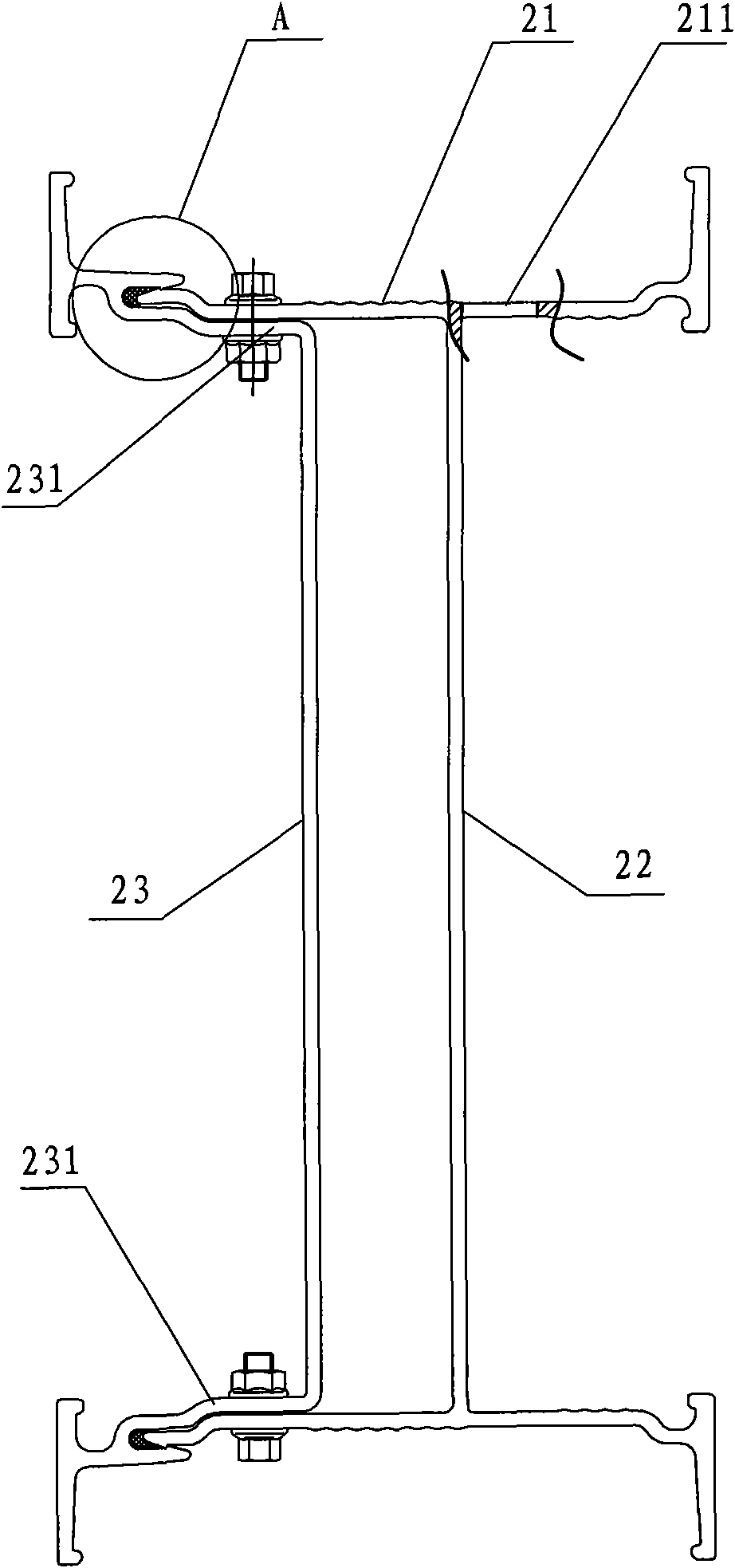

[0013] like image 3 , Figure 4 As shown, the hook-type intensive busway housing includes two upper and lower cover plates 21 and a fixed side plate 22 connected between the two cover plates and biased to one side. The two cover plates 21 are connected to the fixed side The plate 22 is made of an aluminum alloy profile with an overall structure, and a movable side plate 23 with a C-shaped cross section is arranged between the two cover plates to the other side. The cover plate is fixed by bolt or rivet connection. The edges of the two flaps 231 of the movable side plate are folded outwards to form two sealing grooves 232 on the outside, the bottom of the sealing grooves is provided with a sealing strip 24, and the edges of the upper and lower cover plates 21 are inserted into the sealing grooves 232 and Pressed on the sealing strip 24, the edges of the upper and lower cover plates and the side walls of the sealing groove are provided with mutually cooperating grab hooks 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com