Narrow-beam transition section steel mould trolley for tunnel and construction method

A technology of steel formwork trolley and gradual transition section, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of many concrete formwork joints, large construction interference and large construction costs, so as to reduce redesign and processing. cost, reduce construction delamination, reduce the effect of formwork joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

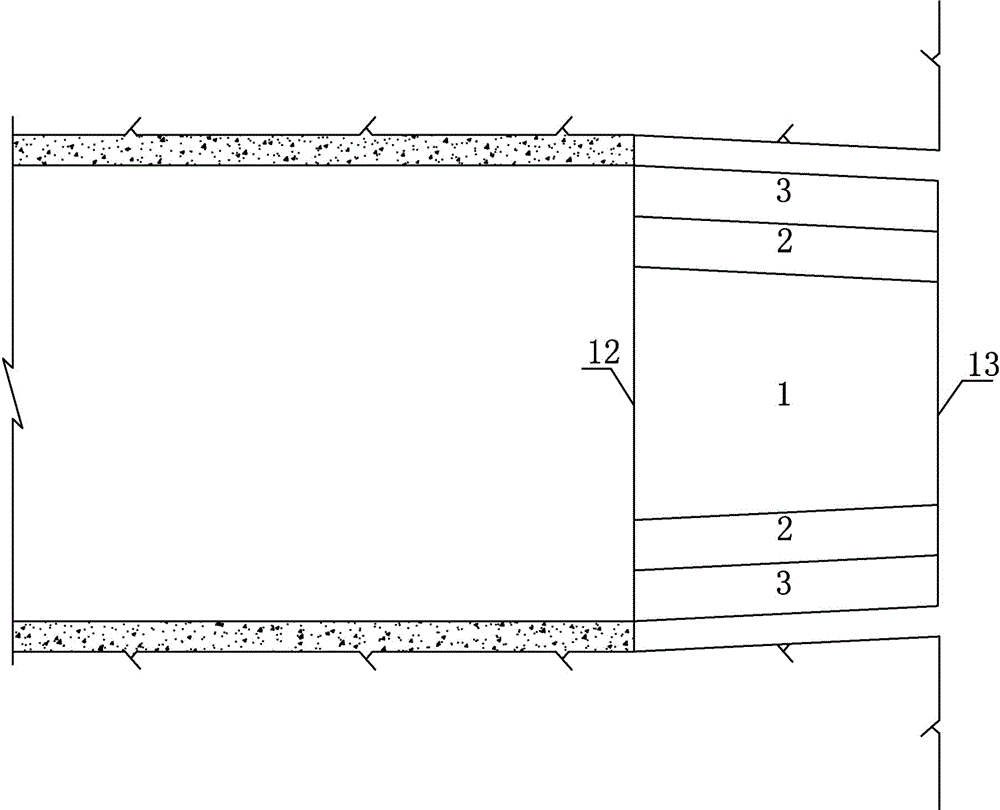

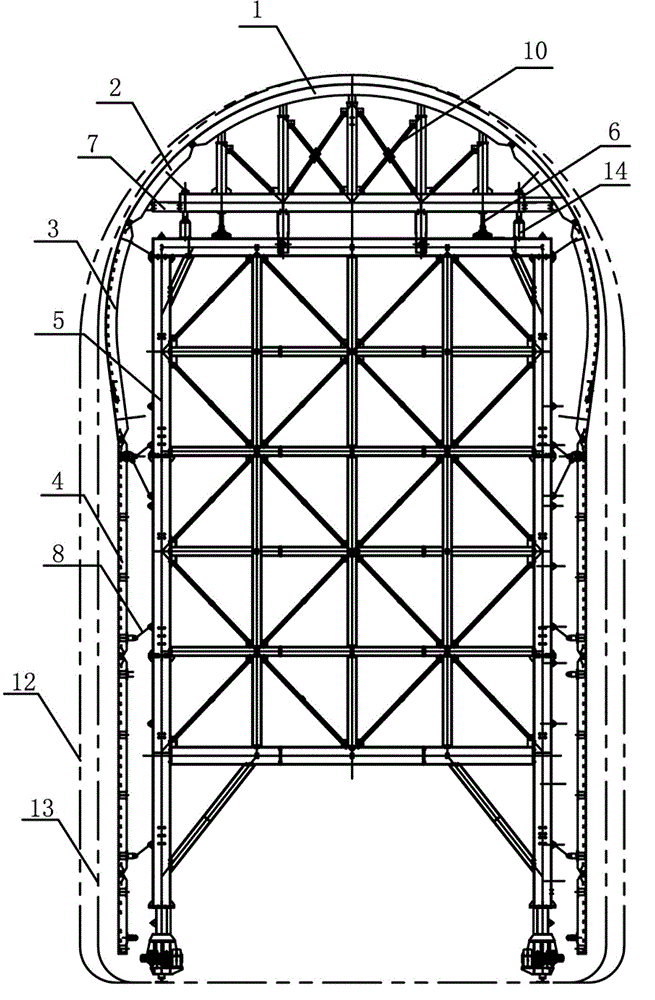

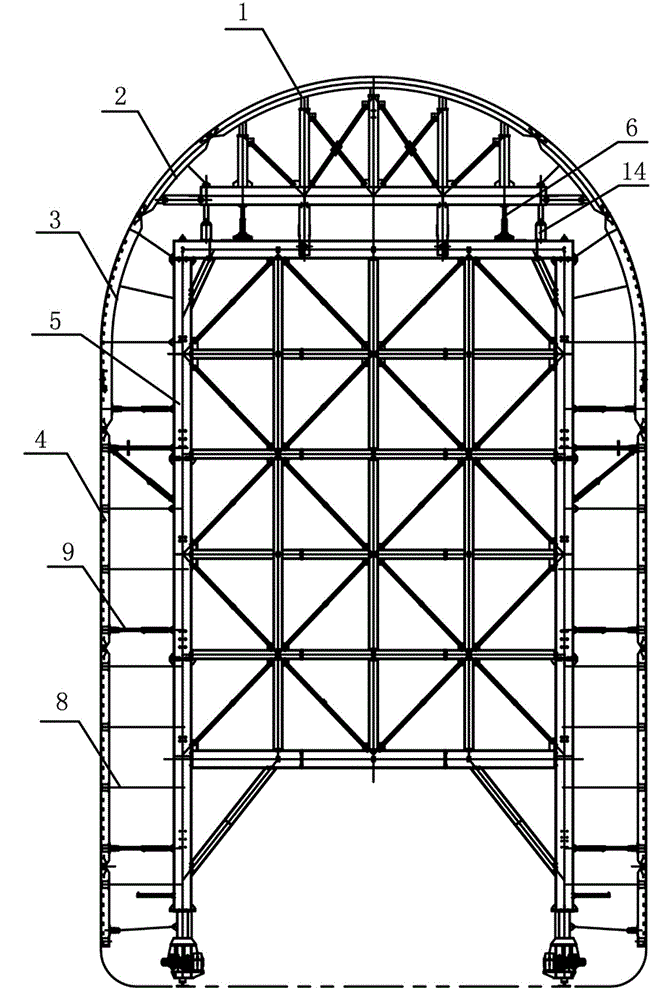

[0035] like figure 1 , image 3 As shown, a concrete lining steel form trolley for the narrow and gradual section of the tunnel bundle includes a trolley door frame 5, a moving assembly is provided at the lower part of the trolley door frame, and multiple sets of tops are arranged between the trolley door frame 5 and the top mold support frame 10. Die lifting cylinder 6 and jack 14, top mold support frame 10 is connected with top mold 1 of gradual change section, both sides of top mold 1 of gradual change section are respectively connected with top mold transition formwork 2, top mold transition formwork 2 is connected with side top formwork 3, side The top form 3 is connected with the side form 4; the transition section top form 1 and the top form transition template 2 are laid on the top form support frame 10; A plurality of hydraulic cylinders 9 are connected and fixed with the trolley door frame 5 . The side form 4 cooperates with the chain block 11 to adjust the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com