Hanging bracket supporting system of side-span cast-in-place section and implementation method thereof

A support system and cast-in-place technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of narrow space and insufficient height between cast-in-place beams and transition piers, and achieve favorable construction quality and material consumption little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

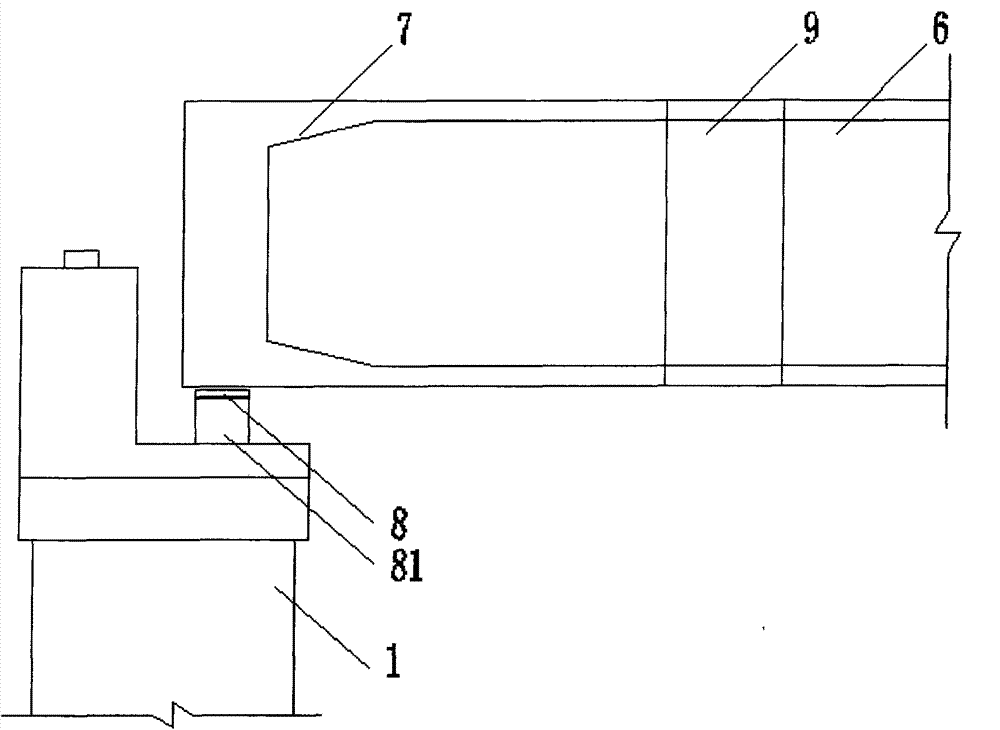

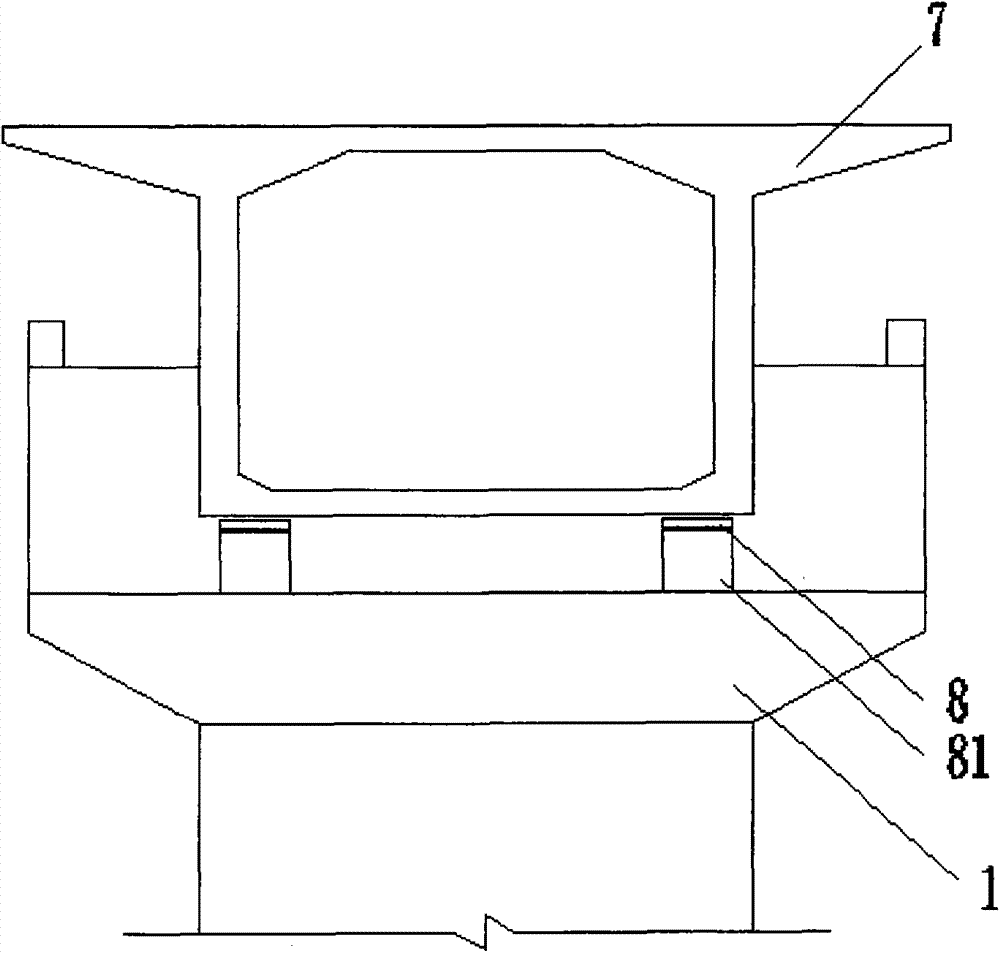

[0037] Such as figure 1 , figure 2 As shown, the design structure of the side span cast-in-place section of a long-span continuous bridge includes transition pier 1, cantilever end beam body 6, cast-in-place beam body 7, closing section beam body 9, permanent support 8 and permanent support Cushion Stone 81. The lengths of the beams in the cast-in-place section and the closing section are 8.31 meters and 2.0 meters respectively, and the height of the beams is 5.0 meters. The construction sequence is: first construct the transition pier 1, then construct the permanent support pad stone 81, and install the permanent support 8; after the cantilever end beam body 6 is completed, construct the side span cast-in-place beam body 7, and finally construct the closing beam body 9.

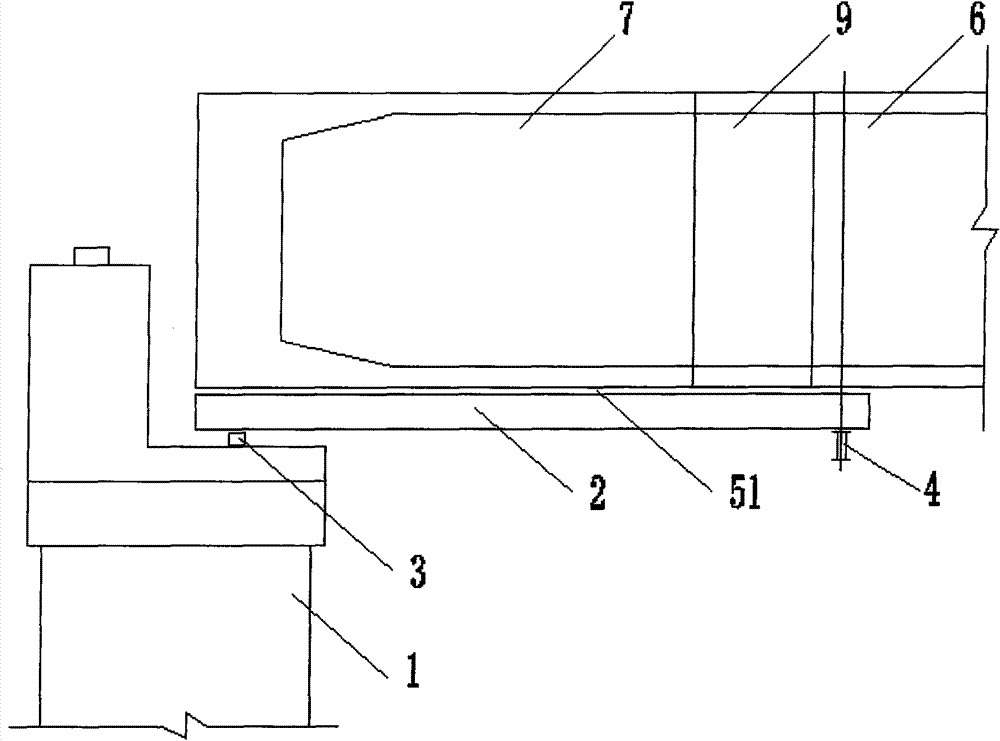

[0038] Such as image 3 , Figure 4 , Figure 5 As shown, the hanger support system of the present invention is composed of several load-bearing longitudinal beams 2, longitudinal beam supports 3, canti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com