Bridge prefabricated hollow pier stud connecting structure and construction method thereof

A technology for connecting structures and hollow piers, which is applied in the direction of basic structure engineering, bridges, bridge parts, etc., can solve the problems of difficult positioning of bridge piers, poor overall mechanical performance, and low structural connection strength, so as to improve the vertical and horizontal Bearing performance, convenient construction operation, and the effect of solving positioning problems and verticality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The design parameters and construction technical requirements of the prestressed anchor cable, the concrete design parameters and construction technical requirements, the manufacturing process of the T-shaped steel plate, etc. will not be repeated in this embodiment, and the embodiments of the structure related to the present invention will be focused on.

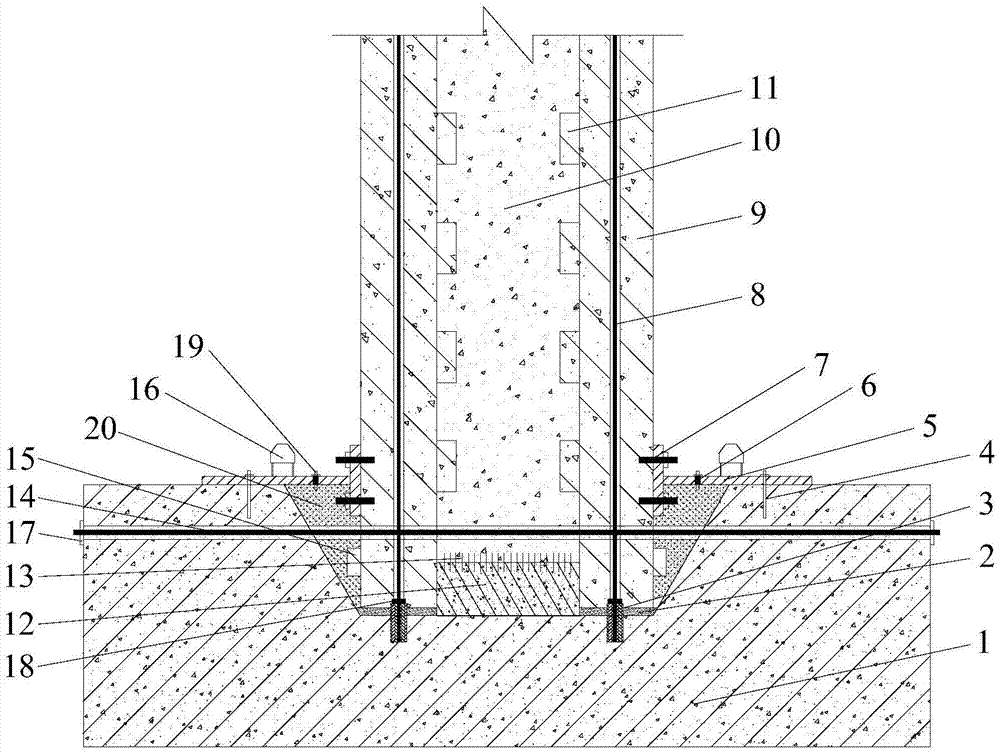

[0034] figure 1 It is a cross-sectional view of the bridge prefabricated hollow pier-column connection structure of the present invention. refer to figure 1 The bridge prefabricated hollow pier-column connection structure shown includes a pier-column foundation 1 and a prefabricated hollow pier-column 9 .

[0035] The pier column foundation 1 is provided with an insertion groove for the prefabricated hollow pier column 9. The cross section of the insertion groove is a trapezoid with a large upper part and a smaller lower part. Anchor cable fixed end 3 and positioning block 12 are installed, and vertical connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com