Thermo electromagnetic forming method of magnesium alloy sheet material

An electromagnetic forming and magnesium alloy technology, which is applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of limiting the application range of flat blank electromagnetic forming technology, uneven distribution of magnetic pressure, and low coil efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 uses AZ31 magnesium alloy sheet material as warm electromagnetic bulging experiment

[0032] 1. Experimental process

[0033] 1. Material preparation:

[0034] The material used in the experiment is the AZ31 magnesium alloy cross-rolled plate provided by Yingkou Yinhe Magnesium Aluminum Alloy Co., Ltd., and its chemical composition is shown in Table 1. The experimental materials were subjected to homogenization annealing treatment, the annealing temperature was 300°C, kept for 1 hour and then cooled in the furnace.

[0035] Table 1 The chemical composition of the AZ31 magnesium alloy sheet used in the experiment

[0036]

[0037] 2. Forming process

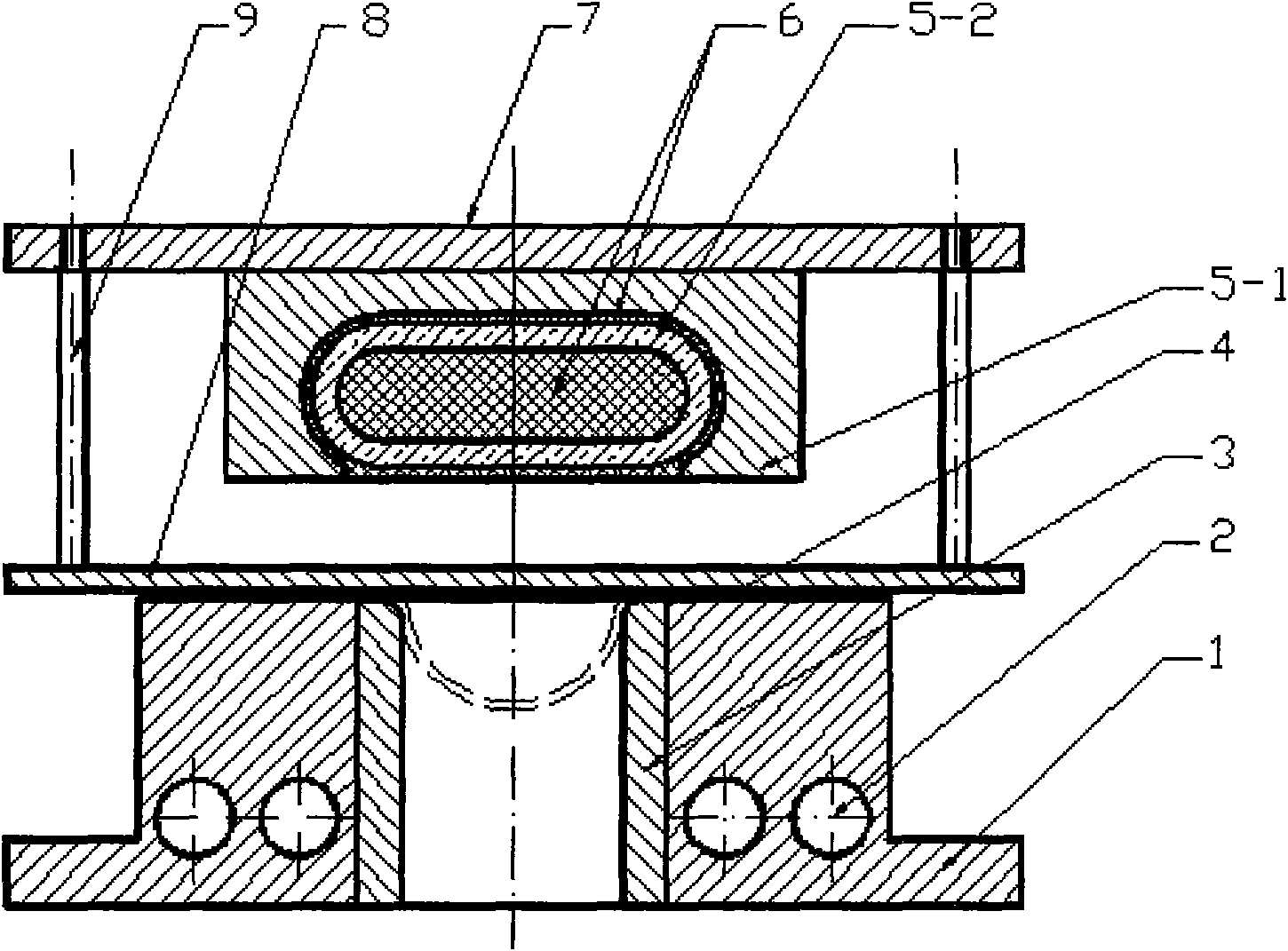

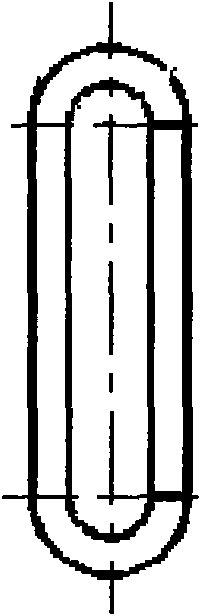

[0038] Electromagnetic bulging test in such as figure 1 Carried out on the tooling structure shown. use Figure 2a , Figure 2b , image 3 The electromagnetic forming coil shown was used for experiments. A rectangular sample with a thickness of 0.5-2.5mm and a thickness of 70mm×100mm is used.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com