Preparation method for energy-saving anti-icing/deicing coating combining super-hydrophobic coating and heating coating

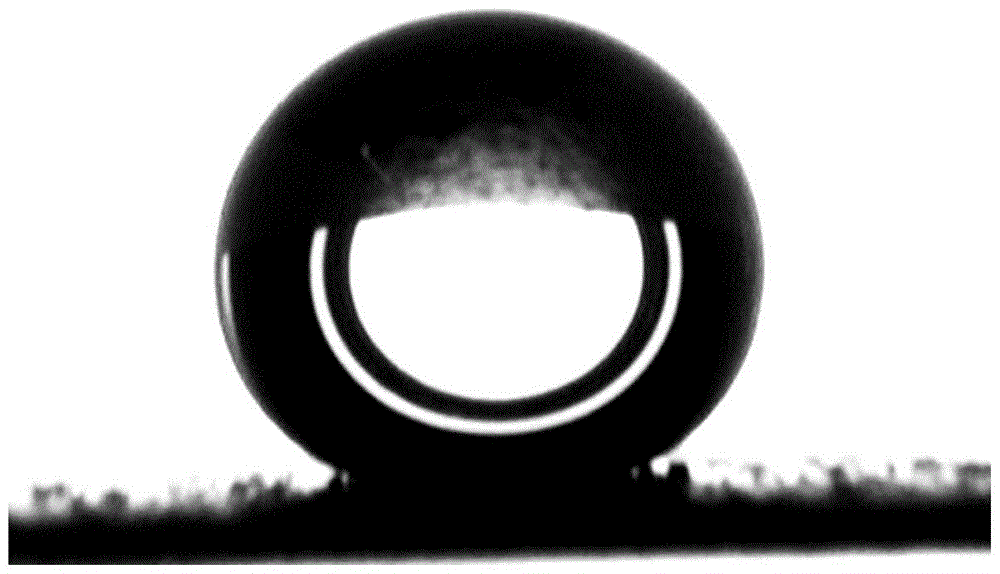

A technology of super-hydrophobic coating and heating coating, which is applied in the direction of coating, liquid coating device on the surface, sustainable manufacturing/processing, etc. It can solve the problem of energy consumption of ineffective electric heating deicing, and achieve efficient and convenient anti-icing , ideal hydrophobic effect, and stable resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

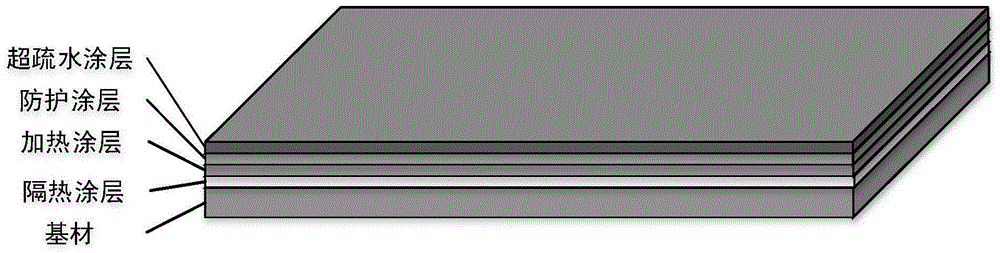

[0041] See figure 1 — Figure 6 , the present invention will be described in detail below through specific examples.

[0042] Step 1: The substrate is sanded or sandblasted, and cleaned repeatedly to obtain a clean and rough surface and improve the bonding force between the coating and the substrate.

[0043] Step 2: Spray a heat-insulating coating on the surface of the treated substrate to prevent heat from being transmitted to the inside of the material and improve thermal efficiency.

[0044]Step 3: After the heat insulation material is completely cured, cover the part that does not need to be sprayed to form a linear arrangement with controllable resistance. Hydrophilic treatment of the surface of the material. Dilute the high-temperature-resistant conductive adhesive with deionized water, stir for 10 minutes, and spray it on the surface of the treated substrate under high pressure. Curing at room temperature for 24 hours, remove the cover after complete curing, fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com