Full-component resource reclamation method for waste positive electrode materials of lithium ion batteries

A technology for lithium ion batteries and positive electrode materials, which is applied to the recycling and re-preparation of waste ternary composite positive electrode materials, and the full-component recycling of waste lithium ion battery positive electrode materials, can solve the problem of low separation efficiency between active materials and aluminum foil, Complex process, secondary pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

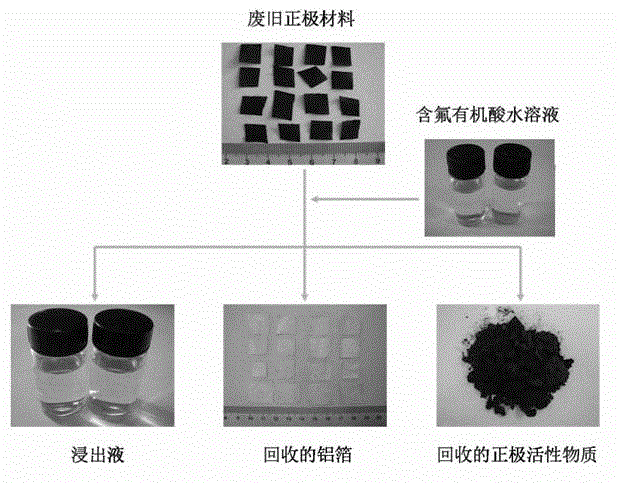

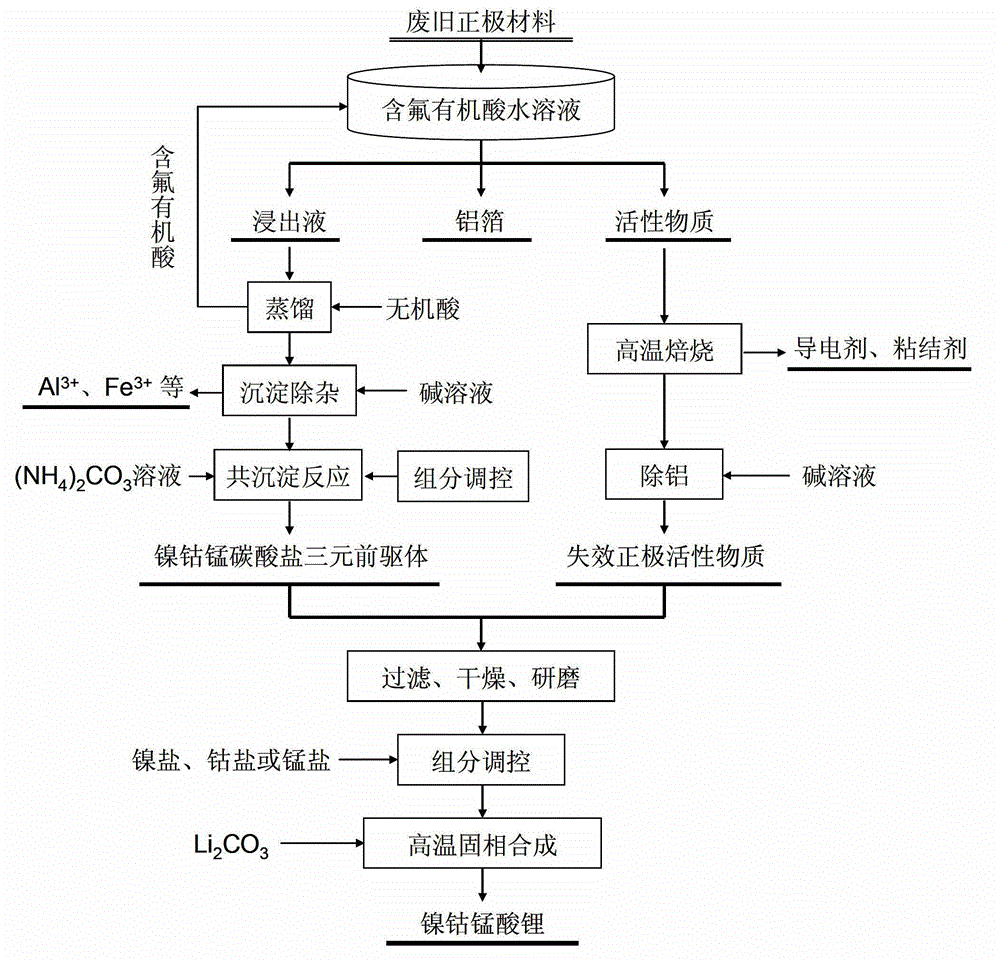

[0044] refer to figure 1 , take about 12.5g of waste nickel cobalt lithium manganese oxide ternary composite positive electrode material after sorting, wherein the binder used is polytetrafluoroethylene, and then prepare battery material grade nickel cobalt lithium manganese oxide according to the following steps. Specific steps are as follows:

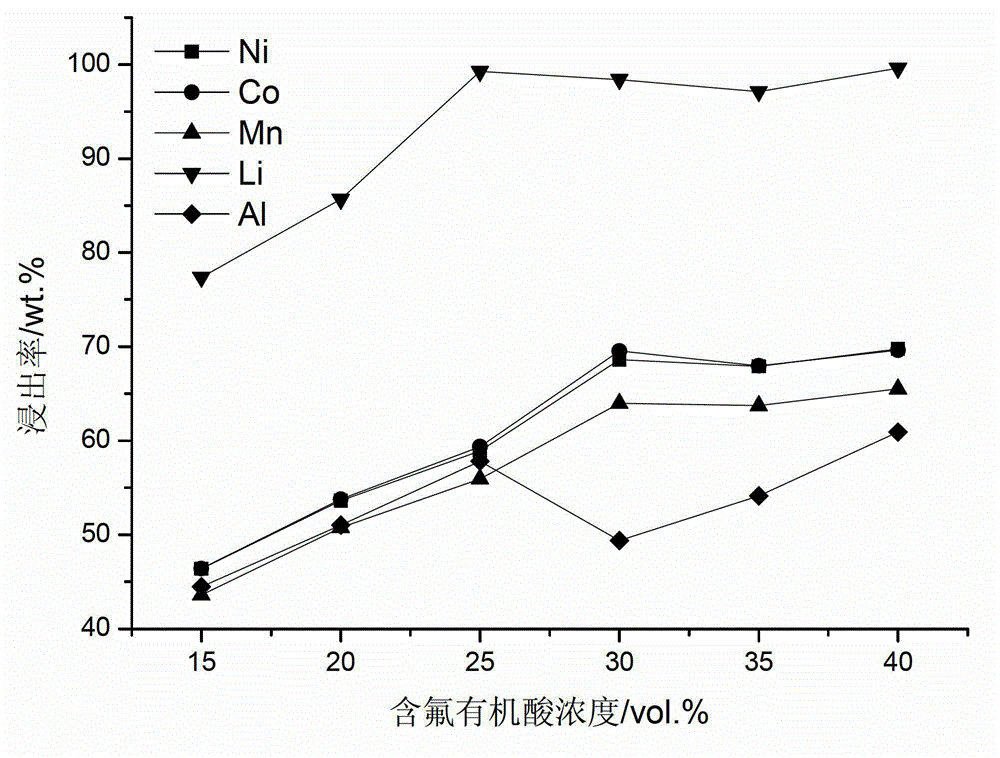

[0045] (1) Add about 12.5g of waste nickel-cobalt-lithium manganese oxide ternary composite positive electrode material after sorting to 100mL of trifluoroacetic acid aqueous solution with a volume concentration of 10%, stir and react in a constant temperature environment of 50°C for 240min, and the reaction is completed Afterwards, liquid-solid-solid separation is carried out to obtain leachate, lithium-containing active material and aluminum foil respectively. The mass content distribution of nickel, cobalt, manganese, lithium and aluminum in the leaching solution, lithium-containing active material and aluminum foil was determined...

Embodiment 2

[0058] Take 15g of a mixture of lithium nickel cobaltate binary composite positive electrode material and lithium manganate positive electrode material waste products in a mass ratio of 2:1, wherein the binder used is polyvinylidene fluoride, and then prepare the battery material according to the following steps Grade Nickel Cobalt Lithium Manganese Oxide. Specific steps are as follows:

[0059] Step (1) ~ step (3) and step (6) are the same as in Example 1, and the rest of the steps are as follows:

[0060] (4) Add 4mol L to the leaching solution obtained in step (1) -1 Nitric acid, and heated to about 80 ° C, using the difference in relative volatility to recover trifluoroacetic acid, used to continue to process waste lithium-ion battery cathode materials, after testing, the recovery rate of trifluoroacetic acid is 80%. Then add 1mol·L to the raffinate after acid heat treatment -1 Potassium hydroxide solution is heated to about 80° C., the pH value of the raffinate is adju...

Embodiment 3

[0068] Take about 30g of a mixture of lithium nickel manganese oxide binary composite positive electrode material and lithium cobaltate positive electrode material scrap with a mass ratio of 2:1, wherein the binder used is styrene-butadiene rubber, and then prepare the battery material according to the following steps Grade Nickel Cobalt Lithium Manganese Oxide. Specific steps are as follows:

[0069] Steps (4) to (7) are the same as in Example 1, and the rest of the steps are as follows:

[0070] (1) Add about 30g of the above-mentioned positive electrode material scrap mixture after sorting to 600mL of trifluoropropionic acid aqueous solution with a volume concentration of 25%, and stir and react in a constant temperature environment of 40°C for 30min. After the reaction is completed, carry out liquid-solid- Solids were separated to obtain leachate, lithium-containing active material and aluminum foil respectively. The mass content distribution of nickel, cobalt, manganese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com