Method for controlling content of silicon tetrachloride in fused salt chlorination process of high titanium slag

A technology of silicon tetrachloride and molten salt chlorination, applied in the direction of titanium halide, etc., can solve the problems of difficulty in the purification of titanium tetrachloride, the inability of the molten salt chlorination furnace to operate stably for a long period of time, and the difficulty in the production of titanium dioxide. The effect of post-processing steps, reduction of production steps, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

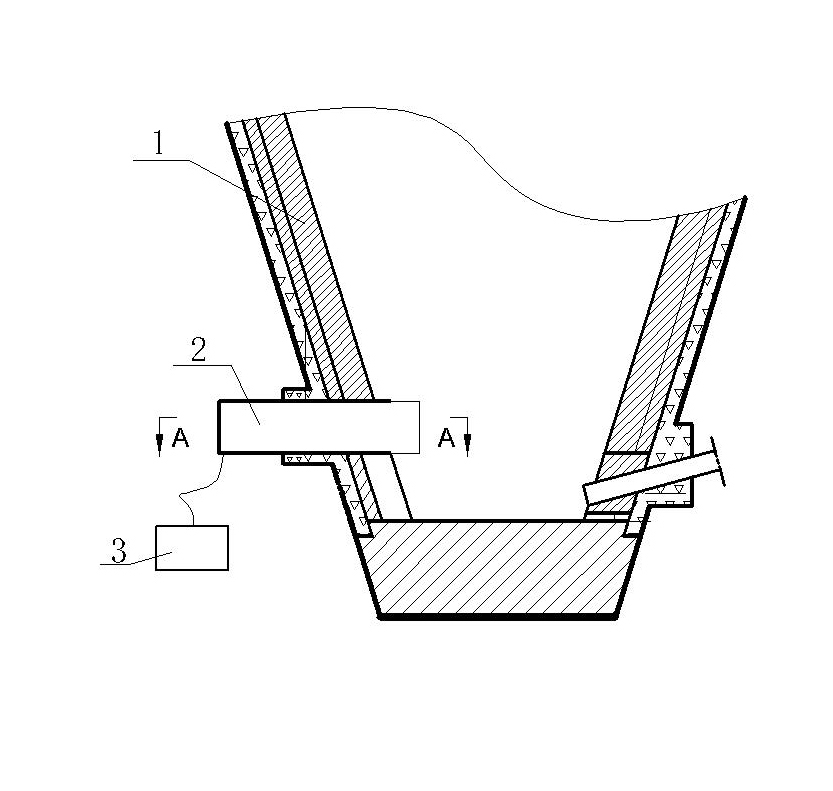

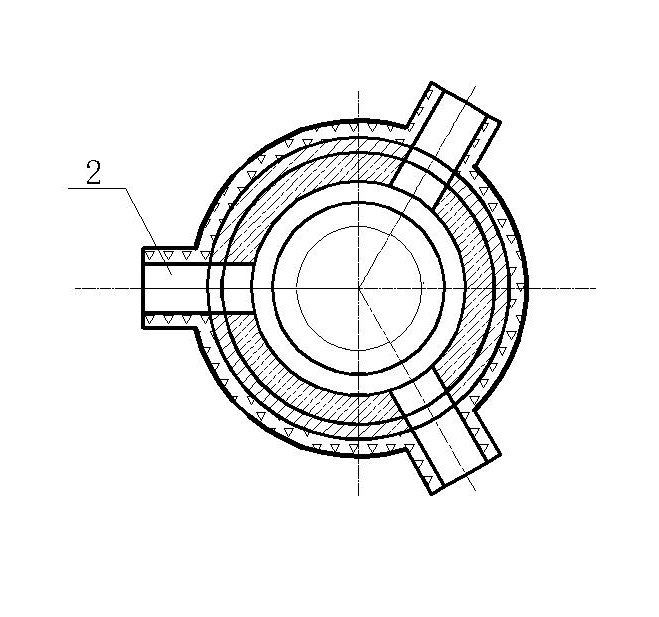

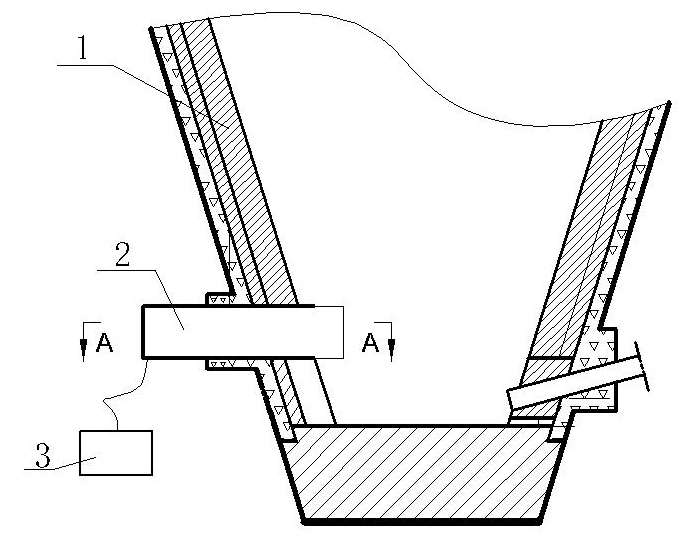

[0011] As shown in the figure, a graphite electrode 2 is connected to the inside of the molten salt chlorination furnace 1, and the graphite electrode 2 is connected to the electric furnace transformer 3, and 45 tons of 700°C-900°C molten sodium, magnesium, Calcium, manganese, iron chloride multi-component molten salt, continuously add 100 parts of high-titanium slag, 10 parts of petroleum coke and 150 parts of chlorine in parts by weight, start the furnace for 1 month, and control the secondary temperature of the electric furnace transformer 3 The voltage is 20V, so that the output current of the molten salt chlorination furnace 1 is 500-800A, and the molten salt current is measured every hour. The change of the resistance of the molten salt is reflected by the change of the measured molten salt current, and then the molten salt chlorination furnace is obtained. The relationship between running time, molten salt current and the mass content of high-titanium slag in molten salt...

Embodiment 2

[0013] As shown in the figure, a graphite electrode 2 is connected to the inside of the molten salt chlorination furnace 1, and the graphite electrode 2 is connected to the electric furnace transformer 3, and 45 tons of 700°C-900°C molten sodium, magnesium, Calcium, manganese, iron chloride multi-component molten salt, add 100 parts of high titanium slag, 30 parts of petroleum coke and 250 parts of chlorine according to the weight ratio, start the furnace for 2 months, and control the secondary voltage of the electric furnace transformer 3 to 50V , so that the output current of the molten salt chlorination furnace 1 is 3200-3500A, and the molten salt current is measured every 2 hours, and the change of the resistance of the molten salt is reflected by the change of the measured molten salt current, and then the operation of the molten salt chlorination furnace is obtained. The relationship between time, molten salt current and the mass content of high-titanium slag in the furna...

Embodiment 3

[0015] As shown in the figure, a graphite electrode 2 is connected to the inside of the molten salt chlorination furnace 1, and the graphite electrode 2 is connected to the electric furnace transformer 3, and 45 tons of 700°C-900°C molten sodium, magnesium, Calcium, manganese, iron chloride multi-component molten salt, add 100 parts of high titanium slag, 20 parts of petroleum coke and 200 parts of chlorine according to the weight ratio, start the furnace for 8 months, and control the secondary voltage of the electric furnace transformer 3 to 30V , so that the output current of the molten salt chlorination furnace 1 is 1700-1900A, and the molten salt current is measured every 90 minutes, and the change of the resistance of the molten salt is reflected by measuring the change of the molten salt current, and then the operating time of the molten salt chlorination furnace, The relationship between the molten salt current and the mass content of high-titanium slag in the molten sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com