High-precision digital template guide belt type direct embossing machine

A high-precision printing machine technology, applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve problems such as excessive labor, high printing defective rate, high energy consumption, etc., to reduce post-processing procedures , Improve production efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

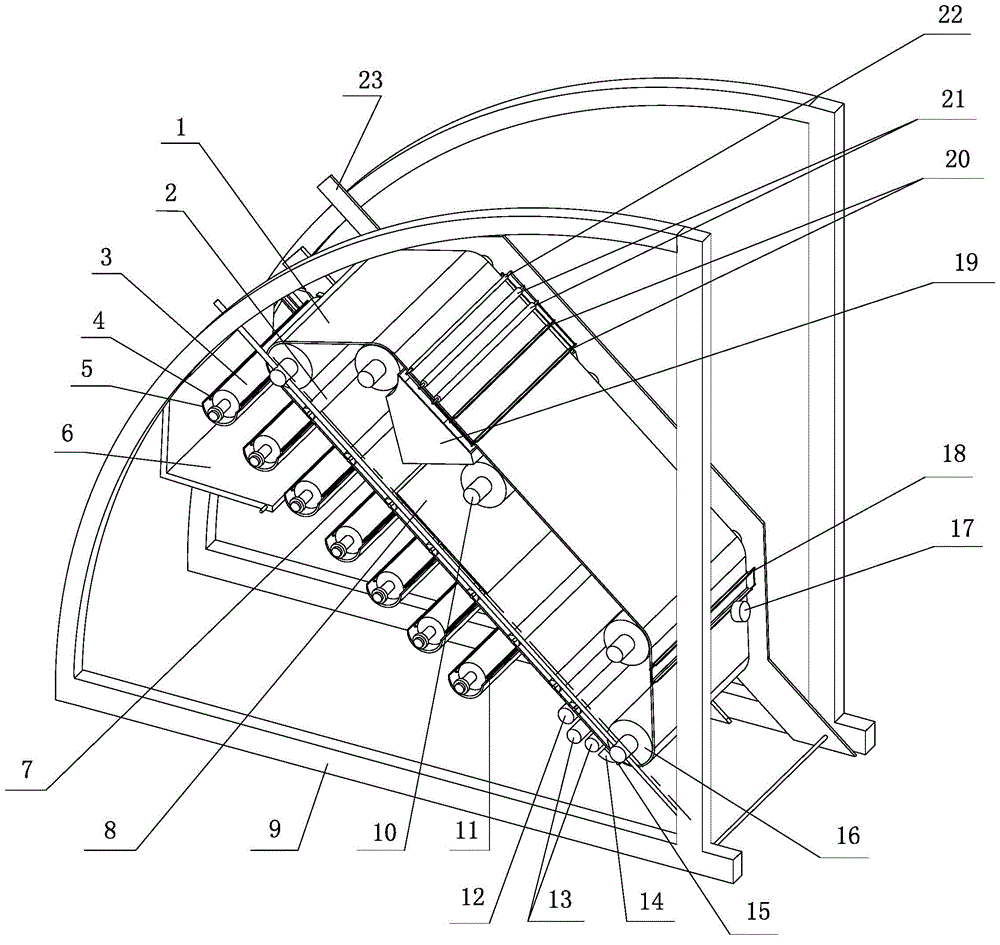

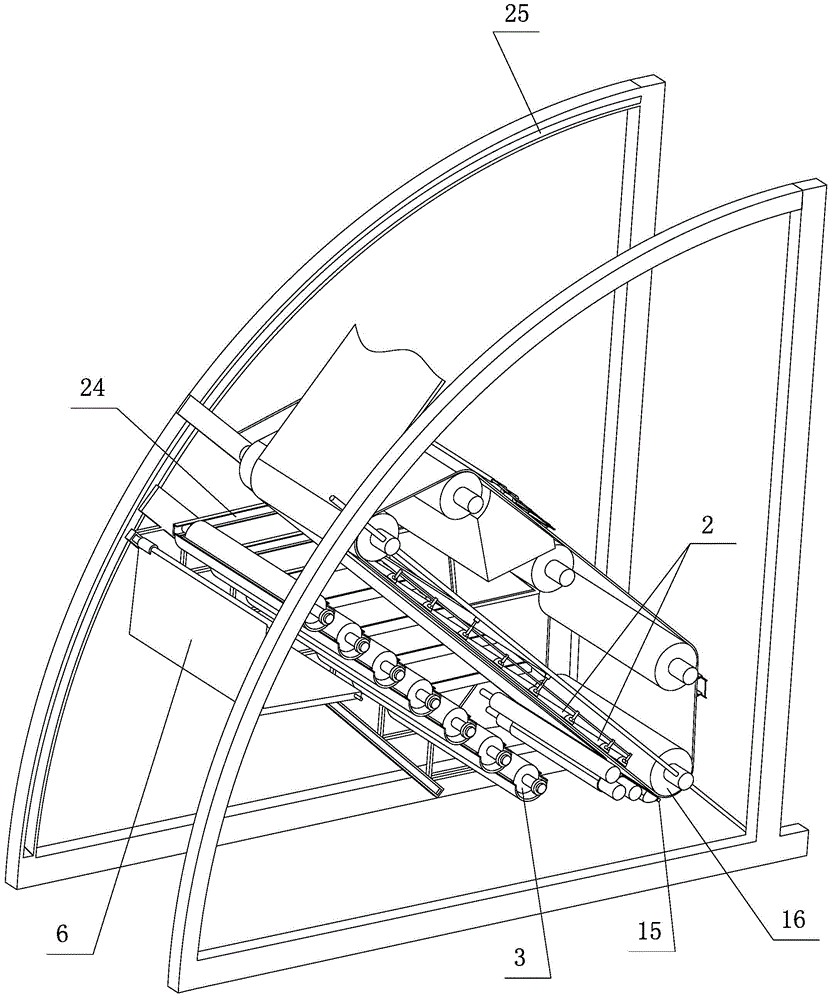

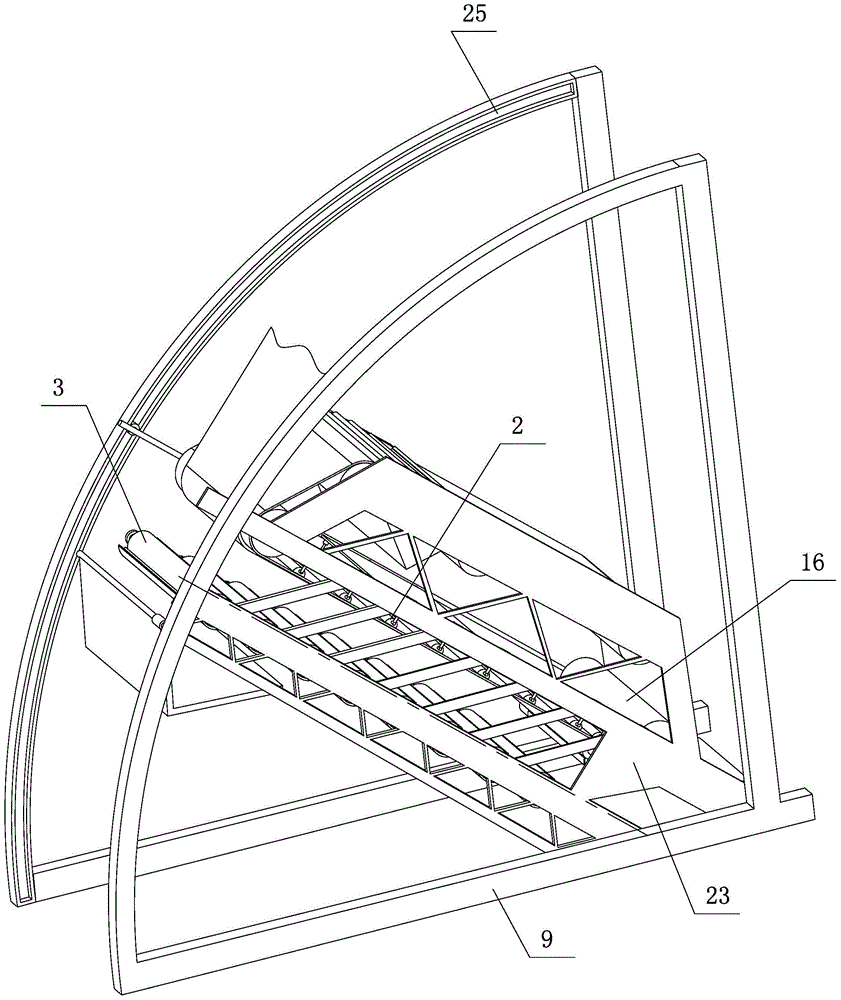

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the high-precision digital board guide belt type direct printing machine of the present invention includes a printing guide belt 1, several high-precision digital template flower rollers 3 arranged in parallel to each other and on the same plane A, and a printing support surface of the printing guide belt 1 The angle B between 7 and the horizontal plane is adjustable from 0° to 90°, the plane A is parallel to the printing support surface 7, and when the angle B is less than 90°, the plane A is located below the printing support surface 7; each A slurry tank 5 is installed directly below the high-precision digital template flower roller 3, and each high-precision digital template flower roller 3 is equipped with a scraper 11, and each group of high-precision digital template flower rollers 3, slurry tank 5, and scraper 11 Driven by the driving mechanism, it can move and position between the original positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com