Method for disassembling and recycling waste refrigerators

A recycling and refrigerator technology, applied in waste treatment, electronic waste recycling, recycling technology, etc., can solve the problems of reduced original value, high energy consumption, high investment and operating costs, so as to increase added value and reduce operating costs , the effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The method for dismantling and recycling waste refrigerators of the present invention comprises the following steps:

[0021] a. First, drill a hole on the pipeline connected to the compressor, and use a conventional refrigerant recovery device (such as a refrigerant recovery machine, model RG5410AE) to recover the refrigerant CFC-12 in the compressor, and recover the refrigerant CFC-12;

[0022] b. Remove the compressor, condensing system, inner partition, tray, and light source accessories from the refrigerator by manual disassembly to obtain directly usable materials and reusable parts; disassembled materials that cannot be directly used manual sorting for reuse or processing;

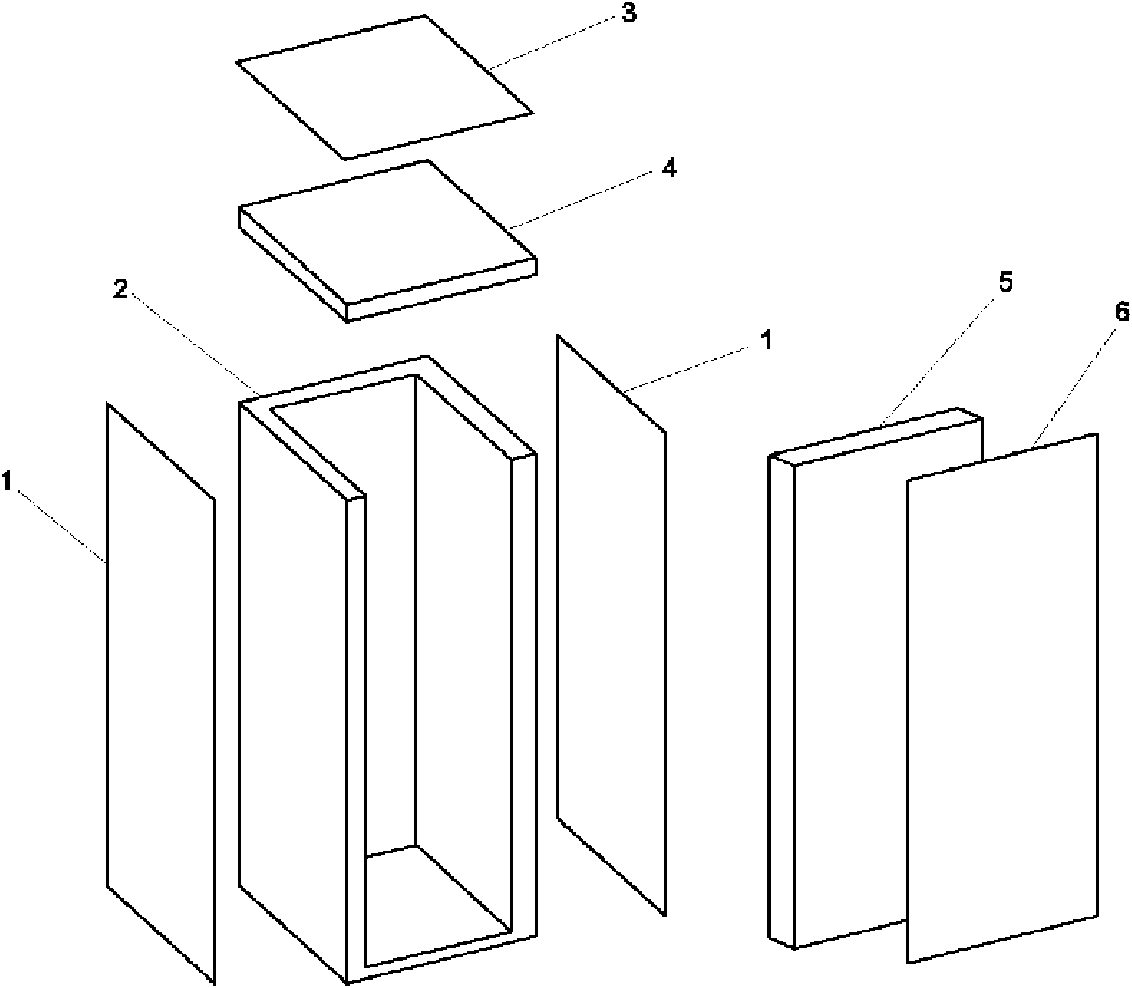

[0023] c. Referring to Fig. 1, in the closed system (the closed system can be a closed workshop), a sampling cutting tool (such as a saber saw, model GFZ 600E, produced by Xiyu Electromechanical Industrial Products Group) first cuts off the top plate 4 of the box body, and the refrigerator R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com