Double-moving-bed reactor, application thereof to flue gas dedusting and denitrating integration device and treatment method

A double moving bed and reactor technology, applied in the field of flue gas purification, can solve the problems of complex device and process, high condition requirements, inability to eliminate poison, etc., and achieve the effect of reducing subsequent processing steps and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

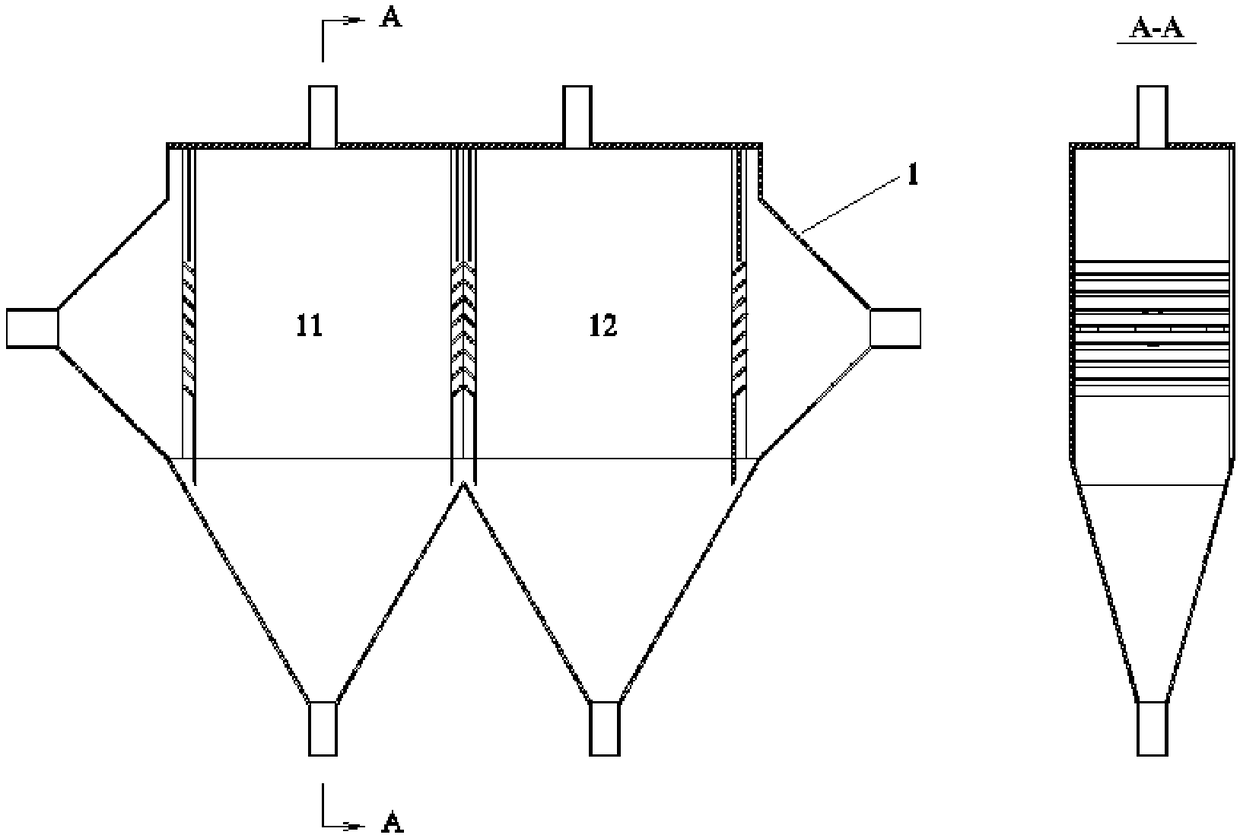

[0086] This embodiment provides a double moving bed reactor 1, and its structure diagram is as follows figure 1 As shown, the double moving bed reactor 1 includes an inlet cavity, a filter bed 11, a catalyst bed 12, and an outlet cavity that are adjacent to each other in sequence, and the inlet cavity, the filter bed 11, the catalyst bed 12, and the outlet cavity are respectively It is separated by the first partition, the second partition and the third partition.

[0087] Wherein, the inlets of the filter bed 11 and the catalyst bed 12 are both located at the top, and the outlets are both located at the bottom.

[0088] The first partition and the third partition are both composed of a louver board, the second partition is composed of two louver boards, the two louver boards are connected together, the distance between the first partition and the second partition The distance between the second partition and the third partition is the same, both are 500 mm.

[0089] The louver boar...

Embodiment 2

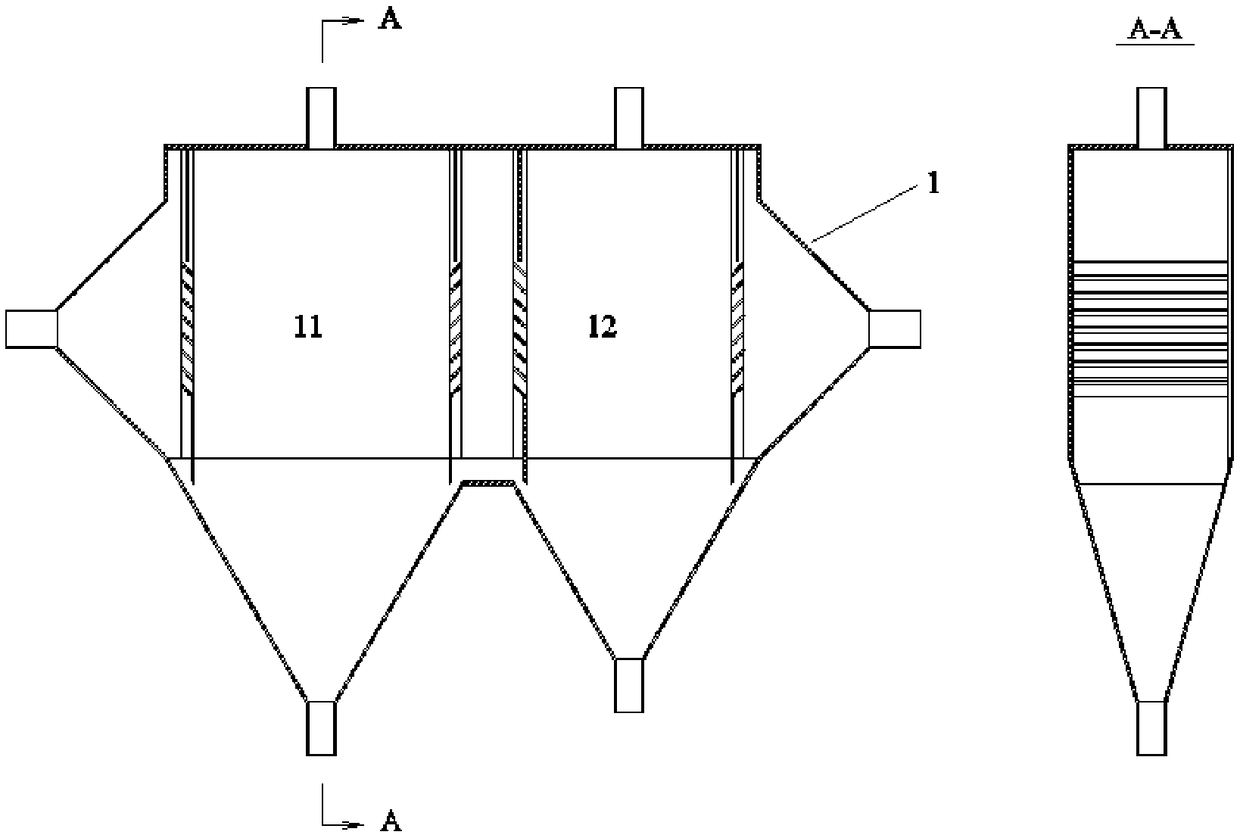

[0092] This embodiment provides a double moving bed reactor 1, and its structure diagram is as follows figure 2 As shown, the double moving bed reactor 1 includes an inlet cavity, a filter bed 11, a catalyst bed 12, and an outlet cavity that are adjacent to each other in sequence, and the inlet cavity, the filter bed 11, the catalyst bed 12, and the outlet cavity are respectively It is separated by the first partition, the second partition and the third partition.

[0093] Wherein, the inlets of the filter bed 11 and the catalyst bed 12 are both located at the top, and the outlets are both located at the bottom.

[0094] The first partition and the third partition are both composed of a louver board, the second partition is composed of two louver boards, the two louver boards are separated by 250mm, and the distance between the first partition and the second partition is 700mm, the distance between the second partition and the third partition is 500mm.

[0095] The louver board is ...

Embodiment 3

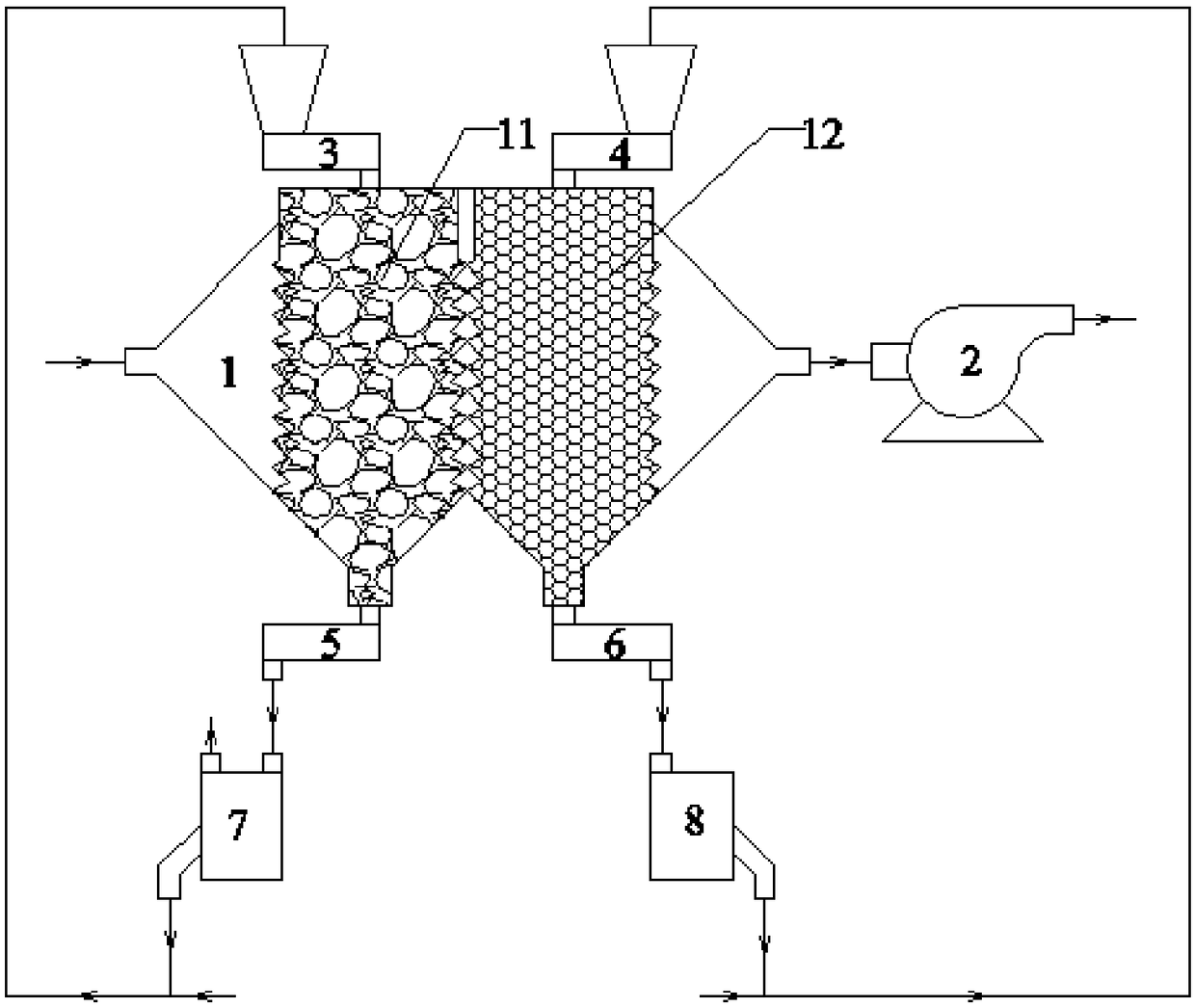

[0098] This embodiment provides an integrated device for flue gas dust removal and denitration. The schematic diagram of the device connection is as follows: image 3 As shown, the device includes the double moving bed reactor 1, a fluidized bed dust removal device 7 and a fluidized bed resurrection device 8.

[0099] Wherein, the structure of the double moving bed reactor 1 refers to Example 1.

[0100] The discharge port of the filter bed 11 in the double moving bed reactor 1 is connected to the feed port of the fluidized bed dust removal device 7, and the discharge port of the fluidized bed dust removal device 7 is connected to the filter The feed port of the material bed 11 is connected, and the feed port of the catalyst bed 12 in the double moving bed reactor 1 is connected to the feed port of the fluidized bed resurrection device 8, and the outlet of the fluidized bed resurrection device 8 The feed port is connected to the feed port of the catalyst bed 12.

[0101] The device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com