Thick material cutting method for dynamically controlling three-dimensional track of laser spot and system of method

A cutting method and three-dimensional trajectory technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficulty in meeting actual processing and production needs, low economic applicability, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

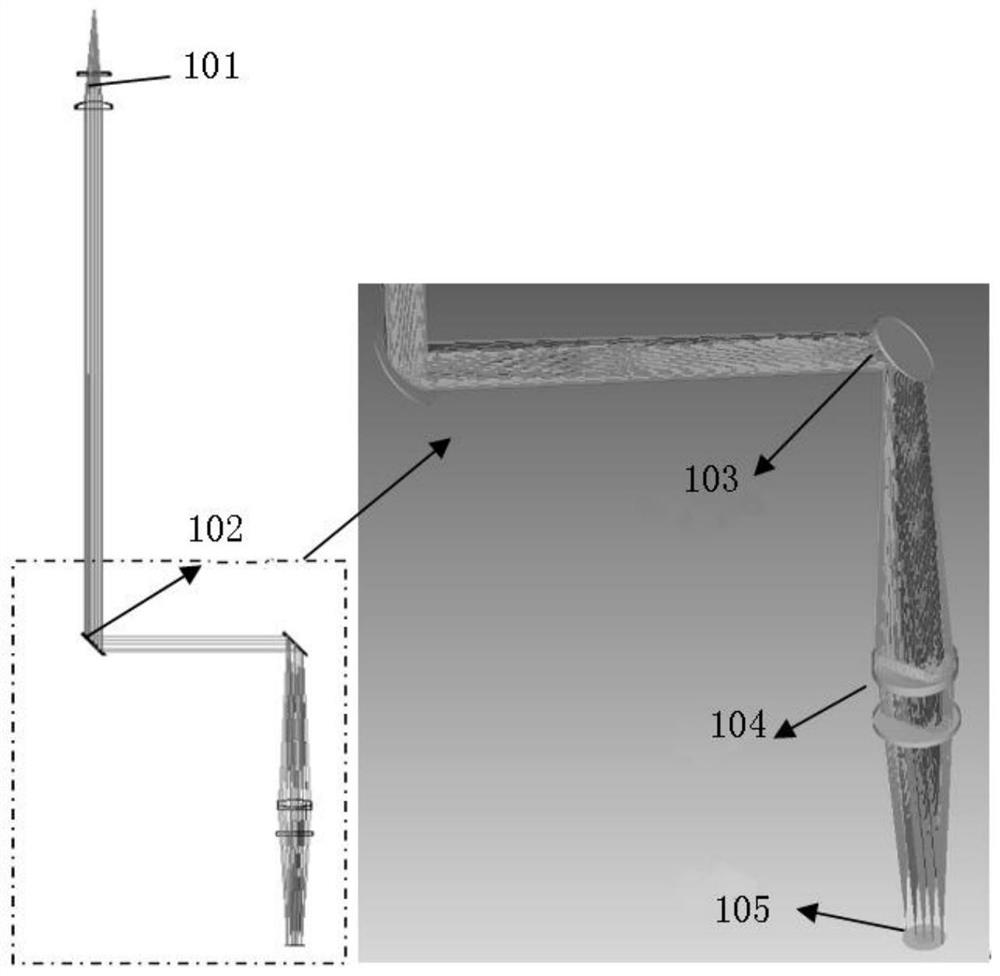

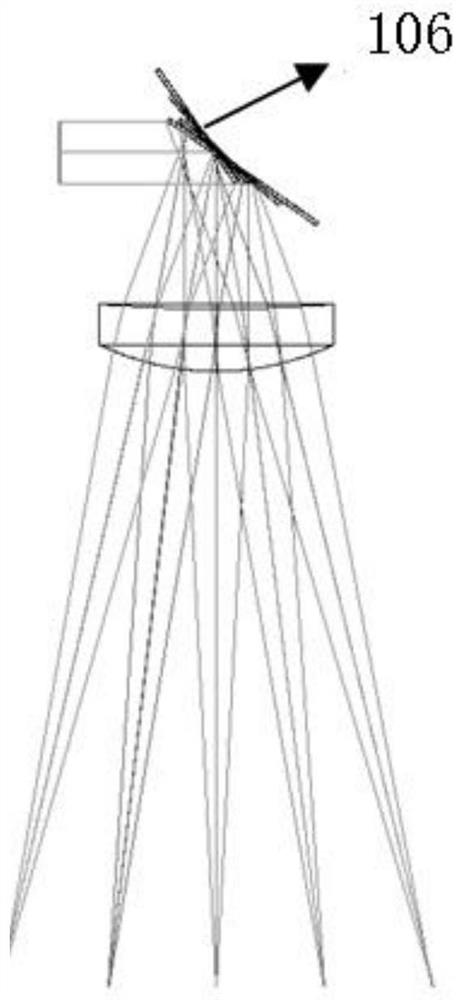

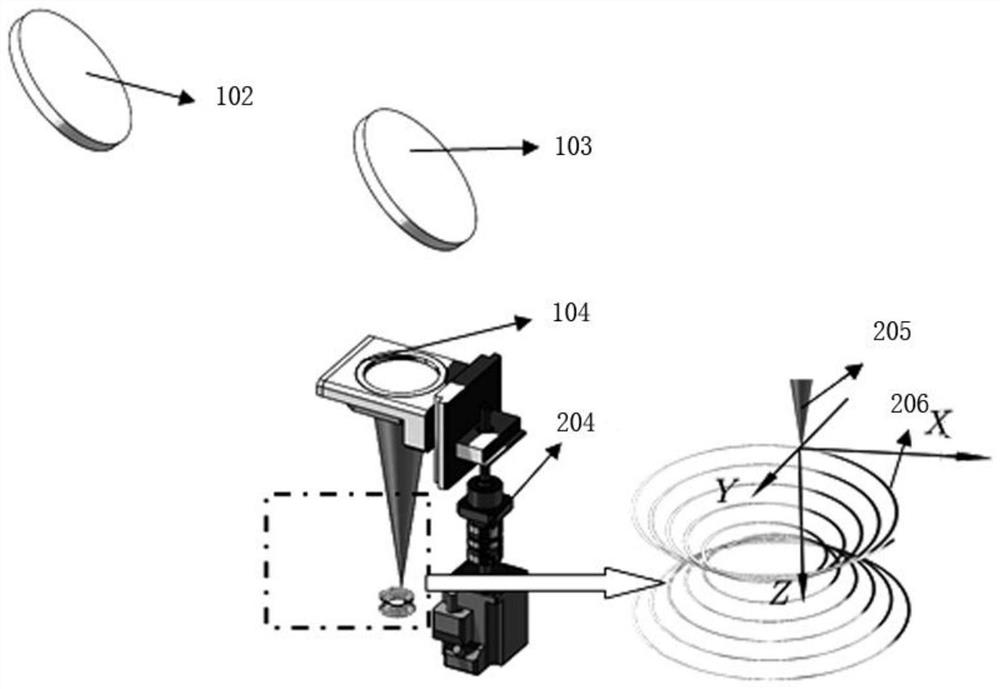

[0057] Such as Figure 1-Figure 3 As shown, a thick material cutting method with dynamic control of the three-dimensional trajectory of the laser spot includes a laser that emits laser light, uses a collimator lens 101 to collimate and distribute the laser beam, and uses a mirror 102 and a vibrating mirror assembly 103 to change the collimation. The optical path of the laser beam uses the focusing lens assembly 104 to focus the collimated laser beam, and the focused laser is shot onto the thick material 105 to be cut, and the focal spot of the laser is controlled to fall in the thick material 105 to be cut, along the predetermined The cutting track moves the focal spot of laser cutting to complete the cutting of thick materials;

[0058]During the cutting process, the focus spot is controlled to perform high-frequency vibration on the cutting track. Among them, the high-frequency vibration with a high-frequency frequency of 20kHz and an amplitude of 20-50μm can optimize the CO...

Embodiment 2

[0094] One of the embodiments of the present invention, the main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0095] In the thick material cutting method, during the cutting process, the focal spot is controlled to perform high-frequency vibration on the cutting track, and the high-frequency frequency is 2.1kHz-3kHz.

Embodiment 3

[0097] One of the embodiments of the present invention, the main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0098] In the thick material cutting method, during the cutting process, the focal spot is controlled to perform high-frequency vibration on the cutting track, and the high-frequency frequency is 3.1kHz-4kHz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com